■ 8

│

GB

│

IE

PBSD900A2

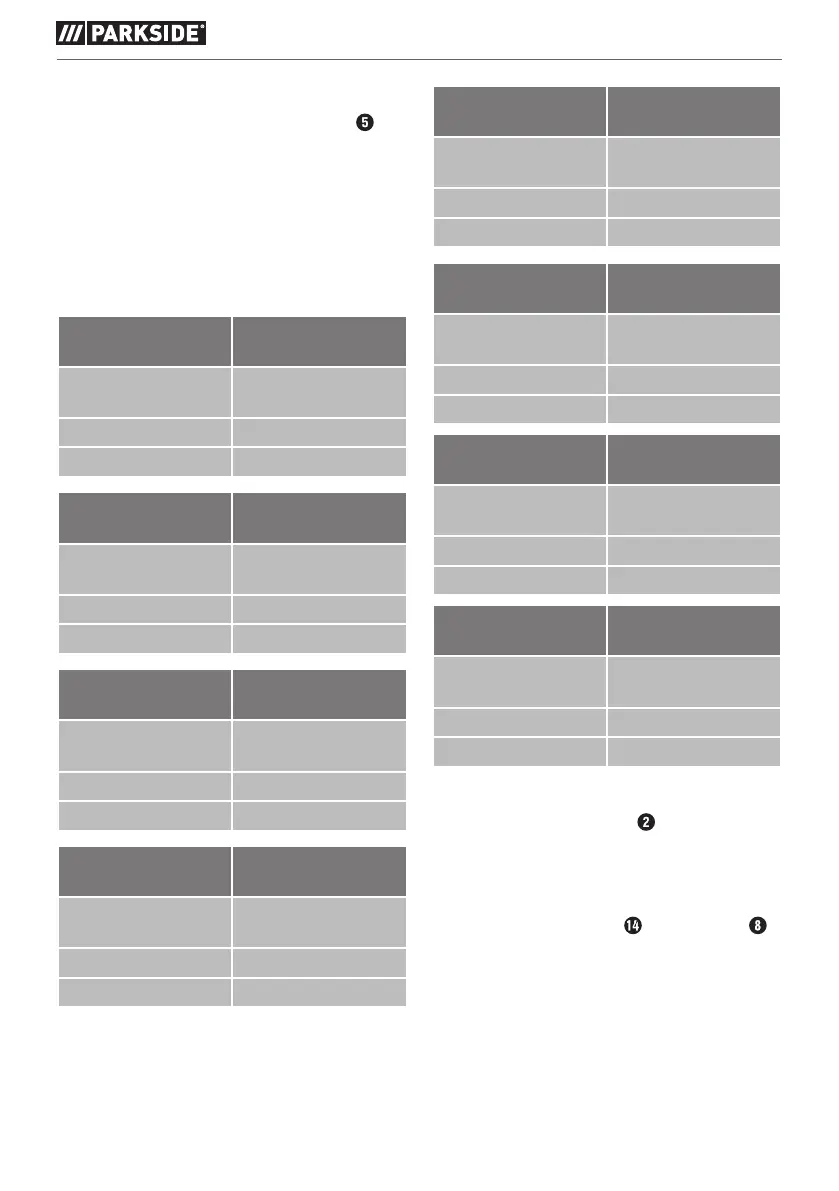

Selecting speed and abrasive belt

You can use the belt speed adjusting wheel to

adjust the speed, even while the appliance is

running. The optimum belt speed is dependent on

the workpiece or material being processed. We

recommend carrying out a practice run to deter-

mine the correct speed. In the table below, you will

find some recommended values which will help you

determine which belt and speed to use for which

job.

Material/

working area

Softwood

Rough sanding

(grain size)

60

Finishing (grain size) 240

Speed preselection high (5–6)

Material/

working area

Hardwood

Rough sanding

(grain size)

60

Finishing (grain size) 180

Speed preselection high (5–6)

Material/

working area

Chipboard

Rough sanding

(grain size)

60

Finishing (grain size) 150

Speed preselection high (5–6)

Material/

working area

Removing

paint/varnish

Rough sanding

(grain size)

60

Finishing (grain size) ––

Speed preselection high (5–6)

Material/

working area

Rubbing down

paintwork/varnish

Rough sanding

(grain size)

150

Finishing (grain size) 320

Speed preselection low (1–2)

Material/

working area

Removing

rust from steel

Rough sanding

(grain size)

40

Finishing (grain size) 120

Speed preselection medium/high (3–4)

Material/

working area

Plastics

Rough sanding

(grain size)

120

Finishing (grain size) 240

Speed preselection low/medium (2–3)

Material/

working area

Non-ferrous metals

(e.g. aluminium)

Rough sanding

(grain size)

80

Finishing (grain size) 150

Speed preselection medium/high (3–4)

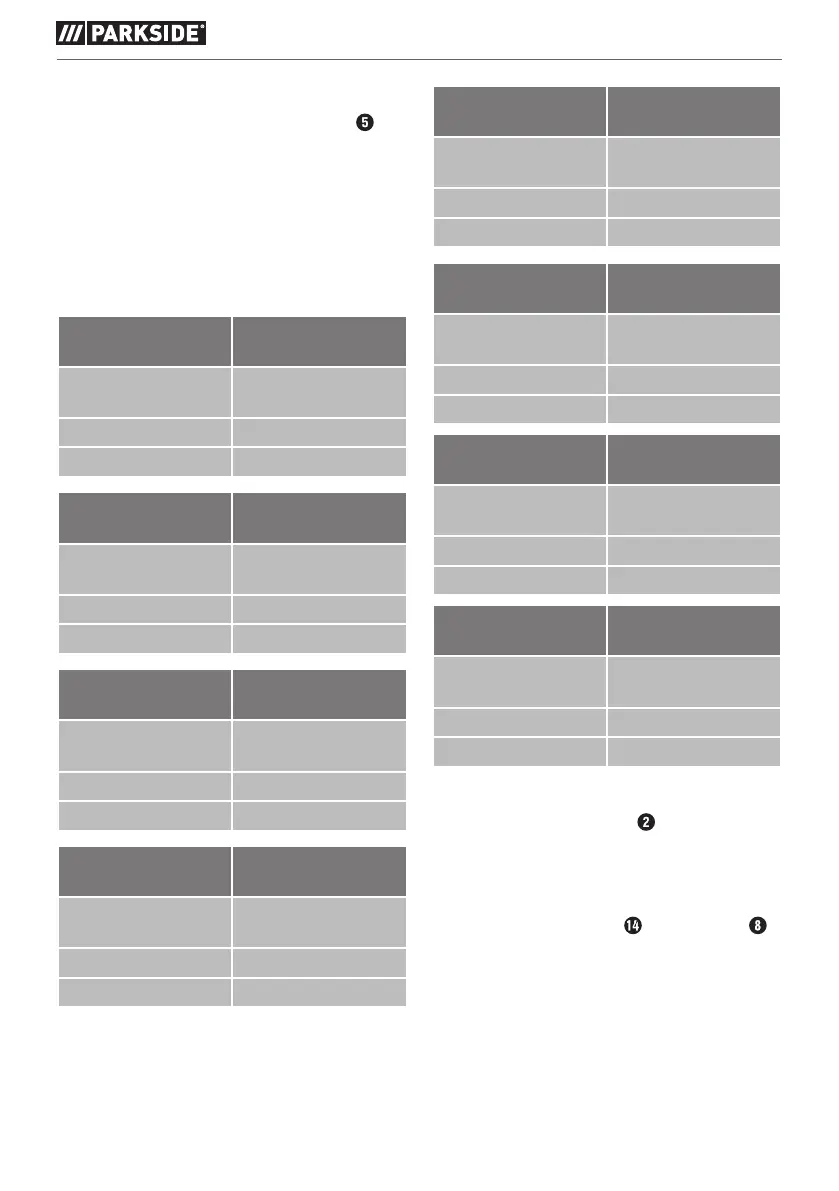

Stationary work

♦ Turn the additional handle to the horizontal

position.

♦ Turn the power tool as shown in the illustration

and place it on a stable worktop.

♦ Fit the two screw clamps

in the recesses

provided and clamp the power tool tightly.

Loading...

Loading...