14

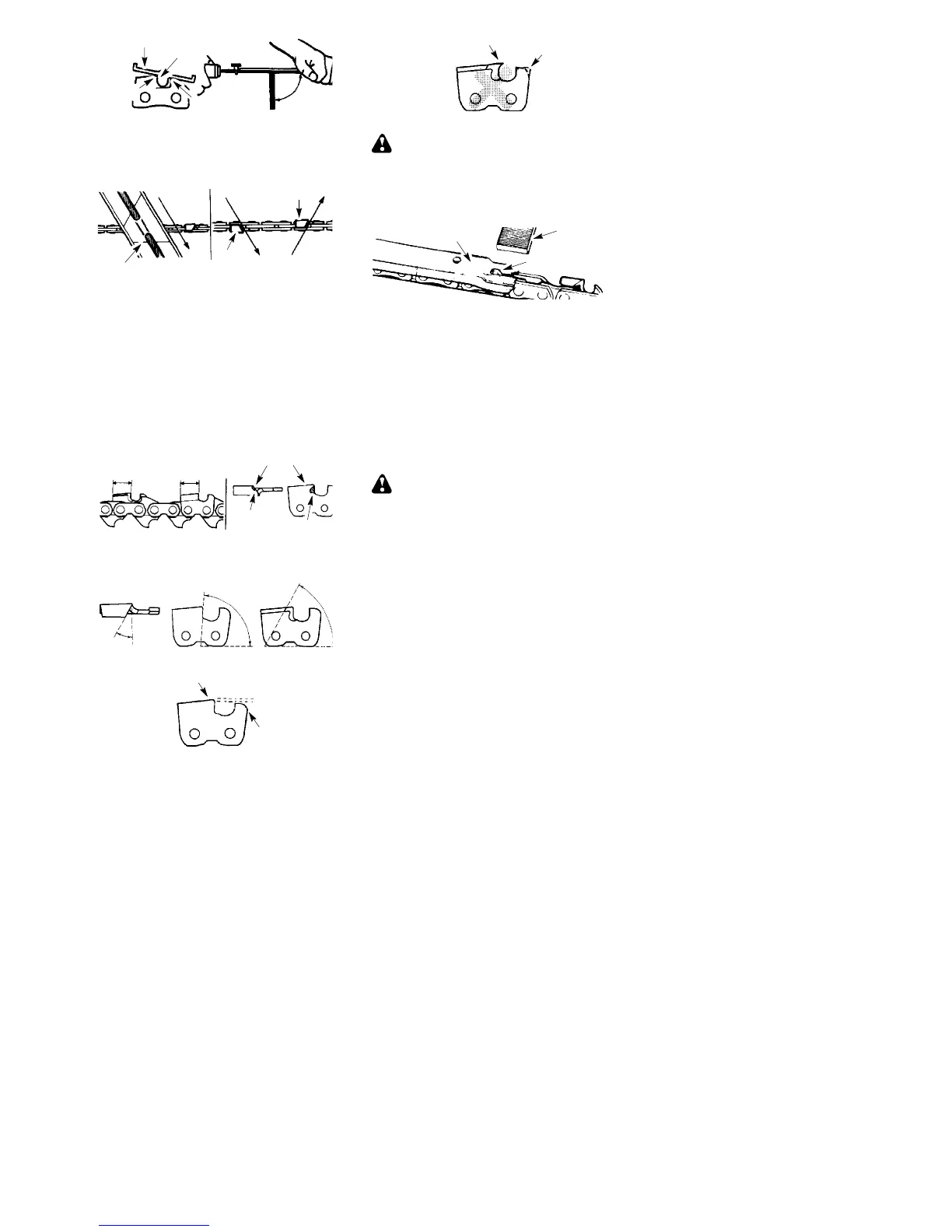

Depth Gauge

File

File Holder

Cutter

90˚

S Align the 30˚ file holder marks paral-

lelwith the bar andto thecenter of the

chain.

Cutter

Cutter

30˚

File Holder Line

S Sharpen cutters on one side of the

chain first. File from the inside of each

cutter to the outside. Then, turn the

chain saw around and repeat the pro-

cess for the other side of the chain.

S File on the forward stroke only. Use 2

or 3 strokes per cutting edge.

S Keep all cutters the same length

when filing.

S File enough to remove any damage

to cutting edges (side plate and top

plate of cutter).

ngle

WARNING: Maintai n the proper hook

angle according to the manufacturer’s specifi-

cations for the chain you are using. Improper

hook angle will increase the chance of kick-

back which can result in serious injury.

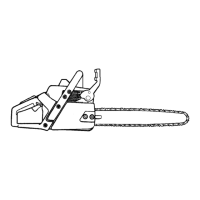

4. Check and lower depth gauges.

Depth Gauge Tool

Depth Gauge

File

S Place gauge tool on cutter.

S If the depth gauge is higher than the

depth gauge tool, file it level to the top of

the depth gauge tool.

S Maintain rounded front corner of

depth gauge with a flat file.

NOTE: The very top of the depth

gauge should be flat with the front

half rounded of f with a flat file.

If you require further assistance or are unsure

about performing this procedure, contact your

authorized service dealer .

CAR B UR E T O R ADJ UST M E N T S

WARNING: Thechainwillbemoving

during most of this procedure. W ear your pro-

tective equipment and observe all safety pre-

cautions. The chain must not move at idle

speed.

The carburetor has been carefully set at the

factory . Adjustmen ts may be necessary if you

notice any of the following conditions:

S Chain moves at idle. See IDLE SPEED--T

adjusting procedure.

S Saw will not idle . See IDLE SPEED--T ad-

justing procedure.

Idle Speed ---T

Allow engine to idle. If the chain moves, idle is

too fast. If the engine stalls, idle is too slow. Ad-

just speed until engine runs without chain

movement (idle too fast) or stalling (idle too

slow). The idle speed screw is located in the

area above the primer bulb and is labeled T.

S Turn idle speed screw (T) clockwise to in-

crease engine speed.

S Turn idle speed screw (T) counterclockwise

to decrease engine speed.

Loading...

Loading...