User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 19

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

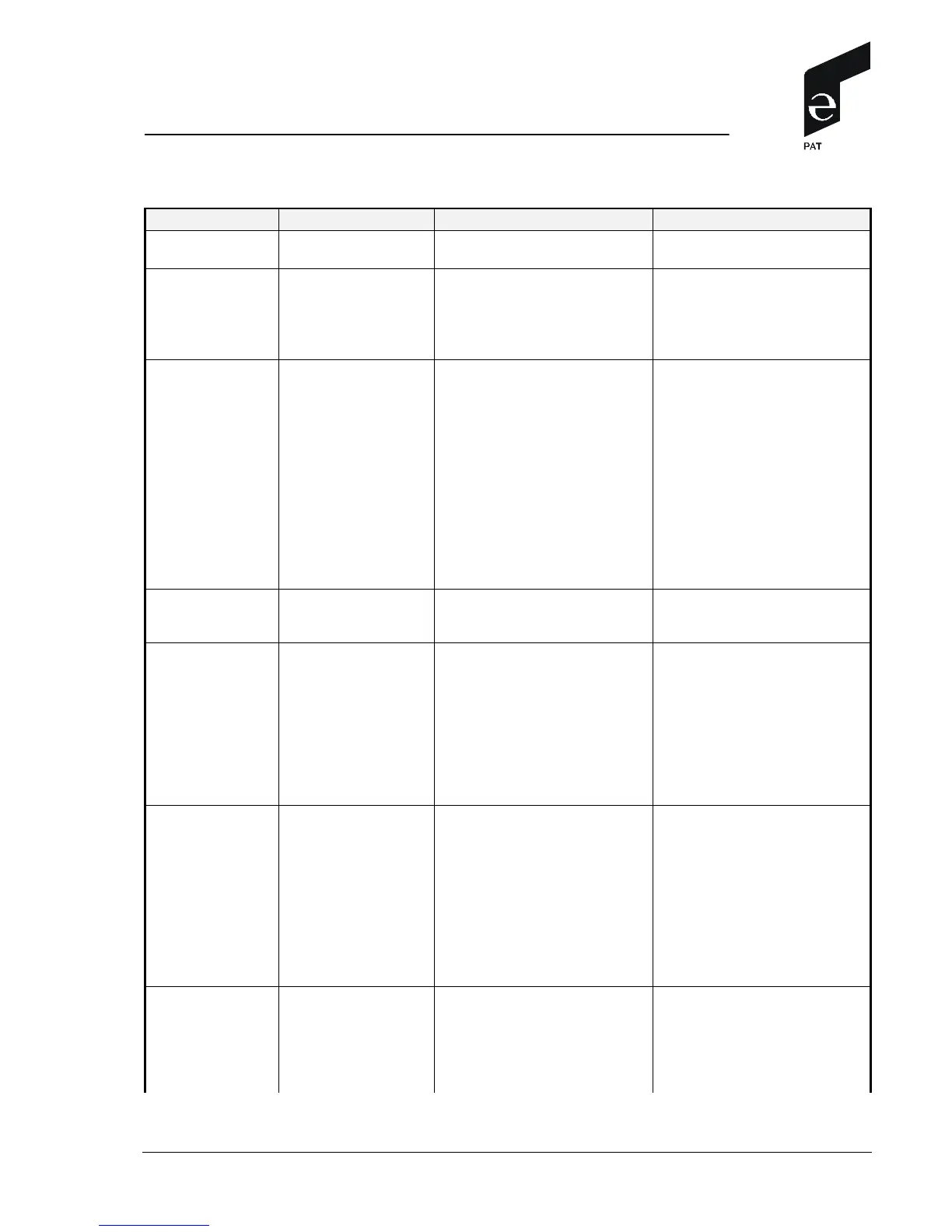

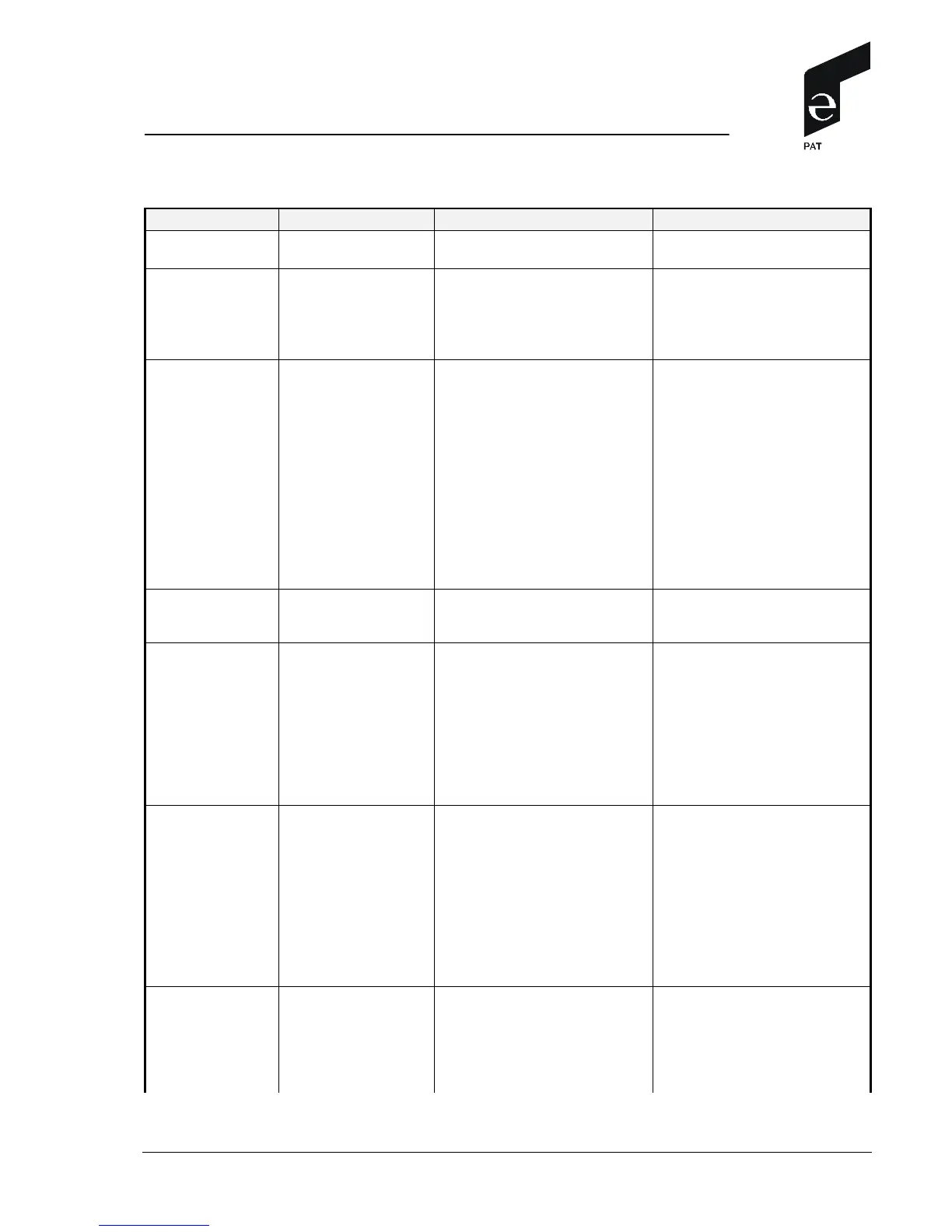

Error Code Error Cause Elimination

• Defective length poten-

tometer

• Replace length potentiome-

ter.

E06

Radius range ex-

ceeded or fallen be-

low angle range with

luffing jib operation

• Maximum radius as speci-

fied in the load chart ex-

ceeded or fallen below

minimum angle due to luffing

down the luffing jib too far

• Luff the jib to a radius or an-

gle specified in the load

chart.

E07

Faulty acknowledg-

ment of the overload

relay on the connec-

tion board.

The relay should be

energized, the 2nd

contact however is

indicated to be off, or

the 2nd contact is in-

dicated to be on

while the relay

should be de-

energized.

• Overload relay or connec-

tion board are defective

• Processor board defective

• Replace connection board

• Replace processor board.

E08

No acknowledgment

from the anti-two-

block relay

• refer to E07 • refer to E07

E10

Error in the length

measurement

• With the boom retracted, the

signal "main boom length"

differs by more than 2 %

from the programmed value

for the basic length

• Check length sensor of the

main boom

• With the boom retracted, the

signal "length Tele I (+II)"

differs by more than 2 %

from the reference value 0

• Check length sensor 2.

E11

Fallen below lower

limit value for meas-

uring channel "length

main boom"

• Cable between central unit

and length sensor is defec-

tive or disconnected. Water

inside the plug of the

length/angle sensor

• Check cable as well as

plugs, replace, if need be.

• Length potentiometer is

defective

• Replace length potentiome-

ter

• Electronic component in the

measuring channel is defec-

tive

• Replace LMI main board or

processor board.

E12

Fallen below the

lower limit value in

the measuring chan-

nel "pressure piston

side"

• Cable between the central

unit and pressure transduc-

ers defective or water inside

the plugs

• Check cable as well as

plugs, replace, if need be.

Loading...

Loading...