Installaon and Inial Start‐Up Instrucons

24

Once the swim spa is in its final locaon perform the following steps to begin the start‐up procedure.

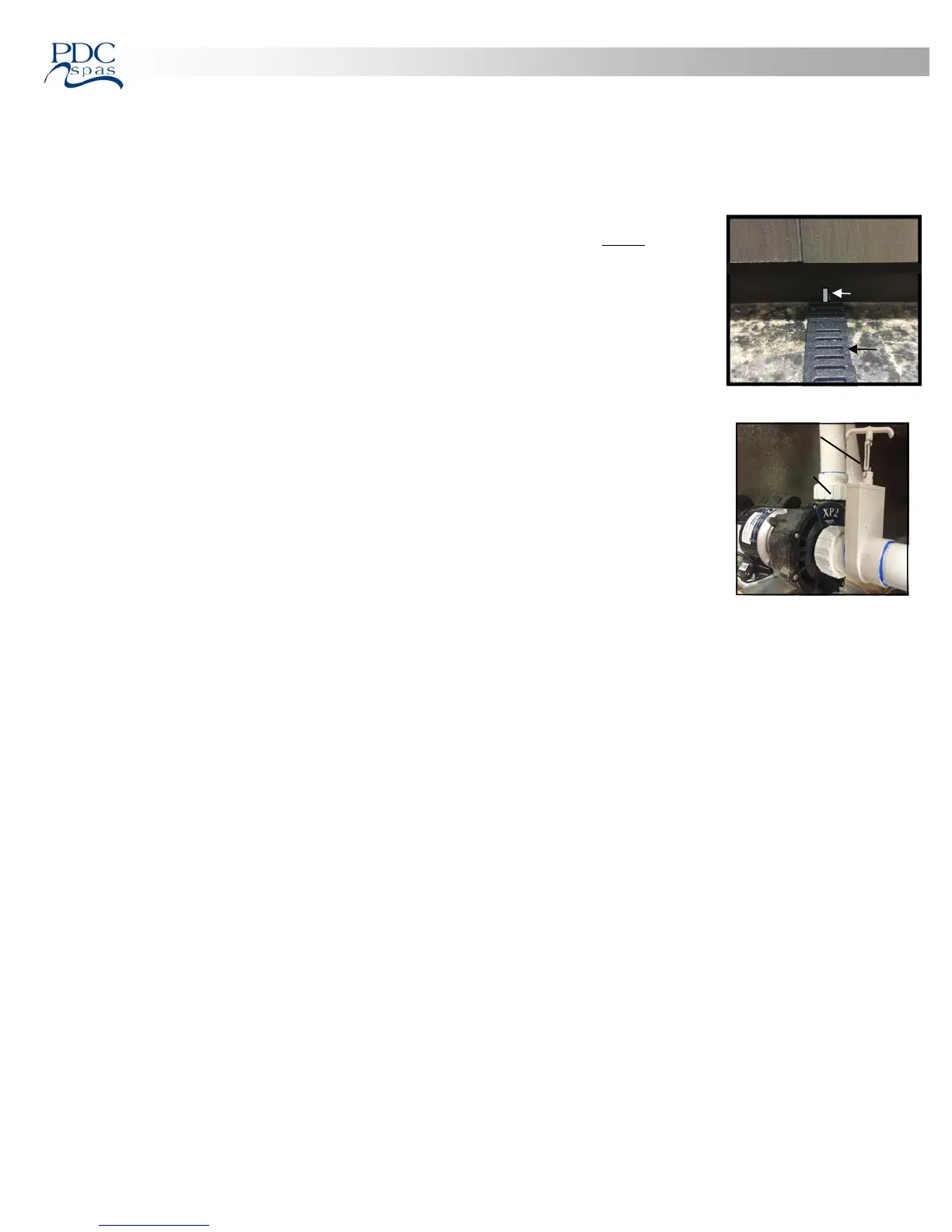

1. Locate white lines painted on the outside of the swim spa base. There are as few as 8 and as many as 14 depending

on the model and series. Insert provided composite shim below the painted line, between

the swim spa base and foundaon. Push shim in by hand unl it stops, then gently tap shim

with hammer unl it stops. Score shim with ulity knife and break off flush with swim spa

base. Photo top right.

2. Consult the specificaon sheet for your specific swim spa model to locate the electrical

spa pack. Remove the cabinet panel exposing pack to complete electric connecon.

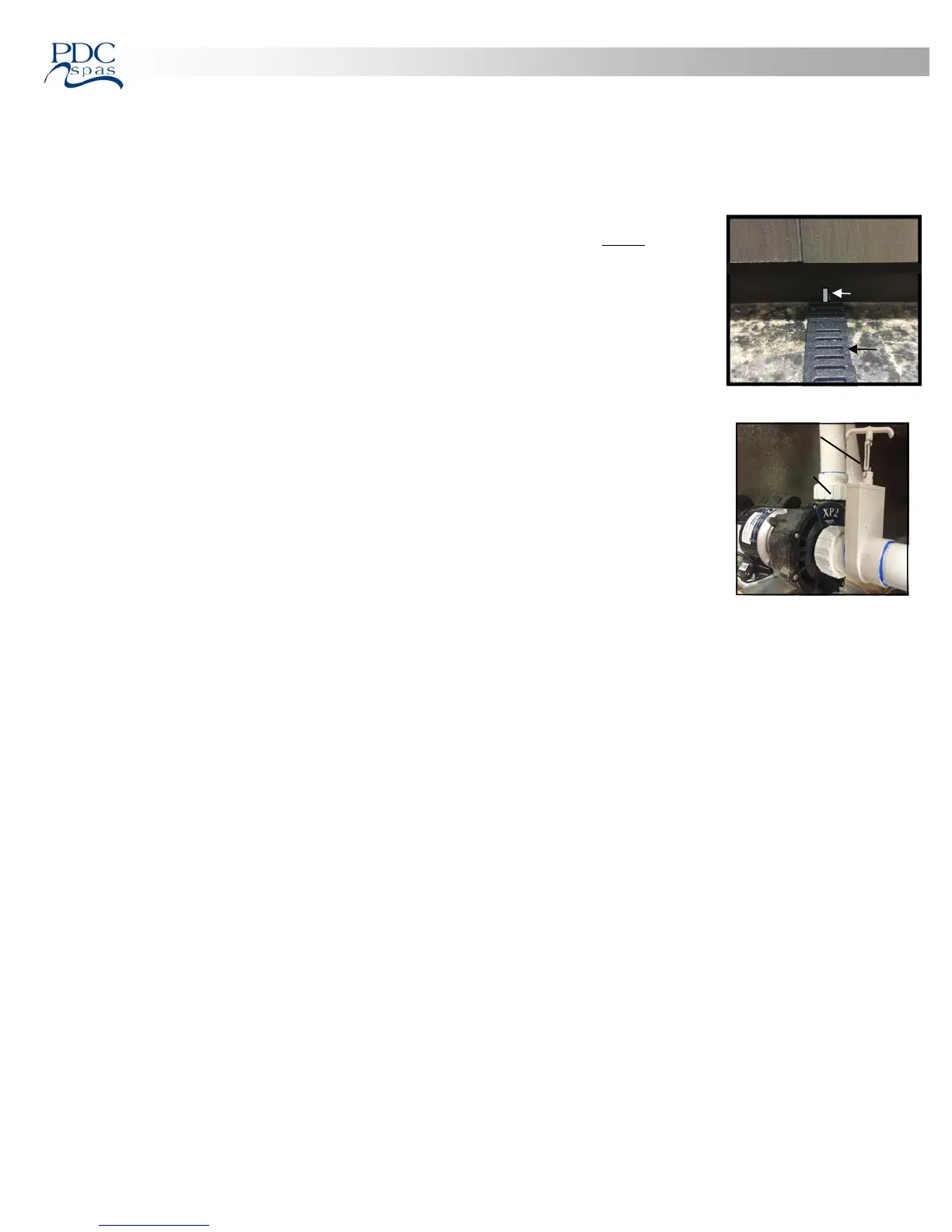

3. Consult the specificaon sheet to locate all the pumps for your specific model, then

remove appropriate cabinet panels. Be sure all pump and heater unions are secure. Each pump has 2 unions, the

heater has 2 unions. The unions of a newly delivered swim spa may have loosened during

transportaon. While checking the unions also check the slide valves are in the up posion

and the lock is installed. Photo boom right.

4. Inspect the swim spa for any dirt or parcles that may have goen on the surface aer

the plasc was removed from the swim spa. Wipe the swim spa with a so damp sponge.

5. For TruSwim® Series models, remove the end cabinet panel and check the hydraulic oil level

of the hydraulic oil reservoir. Oil reservoir should be 3/4 full. If oil is needed, add

biodegradable oil supplied by PDC Spas for TruSwim® propulsion systems only.

6. Ensure your water source is safe for hot tub use. Water may contain minerals that may cause stains or deposits.

Water with high mineral count may discolor the water once a sanizer is added.

7. Let the water run out of your garden hose for several minutes before filling the swim spa. This will flush out stagnant

water in the line that may cause bacteria.

8. Begin filling the swim spa. We recommend filling the swim spa to the top line on side wall. During the filling process

periodically check the unions to ensure they are ght and no water is leaking out. The dual zone models are separate

zones each with their own pack, heater, control. Follow the connecon, filling instrucons for each zone.

9. Once the swim spa is filled turn the circuit breaker on. The spa will turn on and start the circulaon pump.

10. It may be necessary to bleed air from the pump or pumps on your swim spa, if aer start up your swim spa pumps

do not operate. Due to the nature of water flow and hydrotherapy pumps, please be advised that air locking of

pumps may occur. PDC Spas has taken measures to reduce the possibility of this, but it sll may occur, especially

aer refilling a swim spa. This is not a service covered under warranty. To relieve an airlock situaon, loosen the

pump union on the discharge side of the pump. You may possibly hear air come out when union is loosened, aer a

few seconds ghten the union. Turn the pump on to see if proper jet flow has been achieved. If proper jet flow has not

been achieved repeat process.

11. Open air regulators allowing maximum flow through jets assuring pump operaon.

SwimSpaBase

WhiteLine

Composite

Shim

Foundaon

SlideValve

PumpUnion

Loading...

Loading...