44

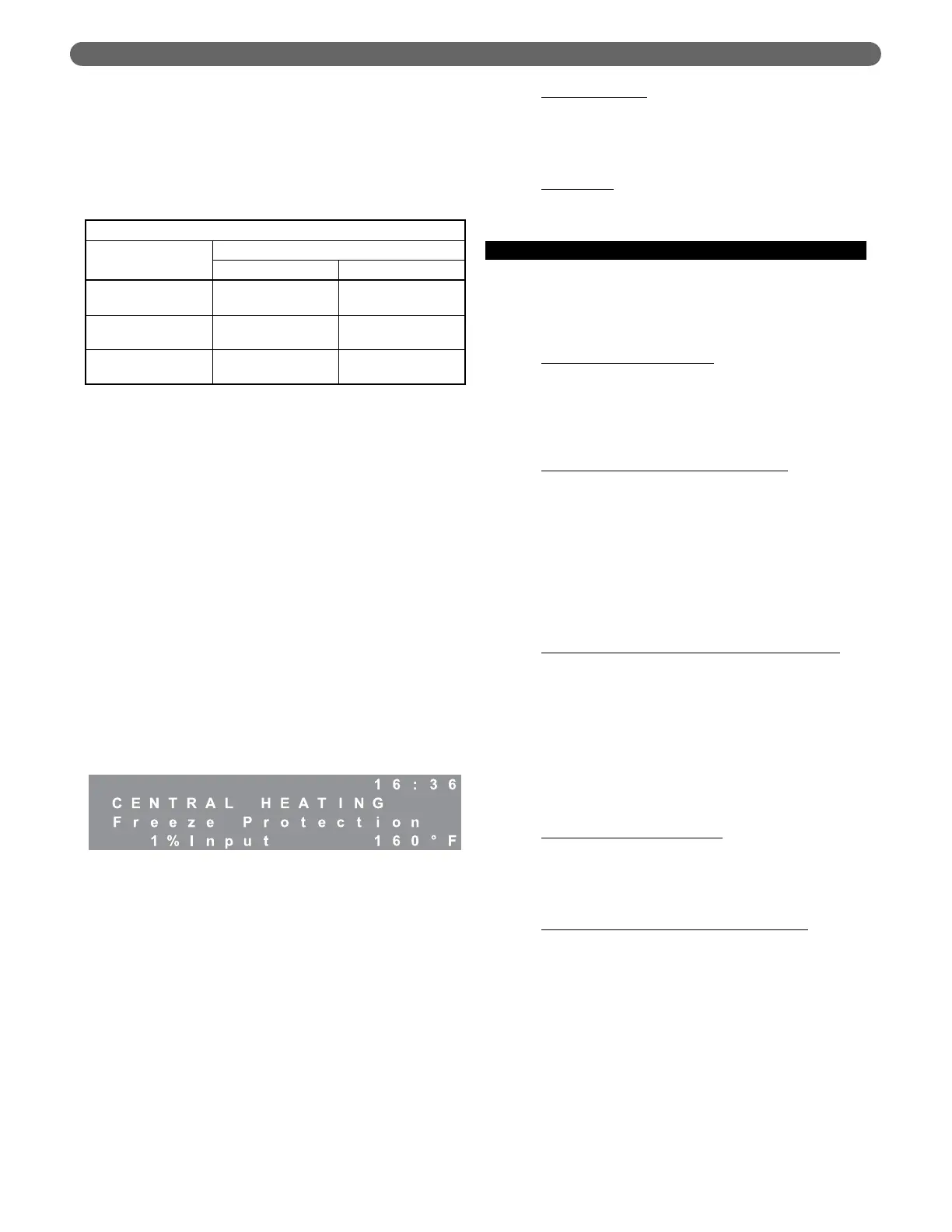

2. Installation Location & Vent Material:

The P

UREFIRE

®

boiler allows the installer to input the

installation location and the vent material used. This

information is used to determine the suitable vent

temperature limit based on National Codes. Table 8.6

shows the vent temperature limit based on the

location and vent material.

The P

UREFIRE

®

control will reduce the boiler firing rate

if the vent temperature approaches the vent

temperature limit. If the vent temperature continues to

rise, the control will shut down the boiler.

3. Freeze Protection:

The P

UREFIRE

®

boiler control is intended to prevent

the central heating system from freezing. The default

temperature to activate this function is 50°F (10°C).

If the supply temperature drops to below the freeze

protection setpoint, the general pump and/or the CH

pump (depending on pump mode) will be activated. If

the supply or return temperature drops more than 9°F

(5°C) below the setpoint, the control lights the boiler

using the ignition sequence described in section 8.B.

The control will operate the burner at minimum

power until the both the supply and return boiler

temperature are more than 9°F (5°C) above the freeze

protection setpoint.

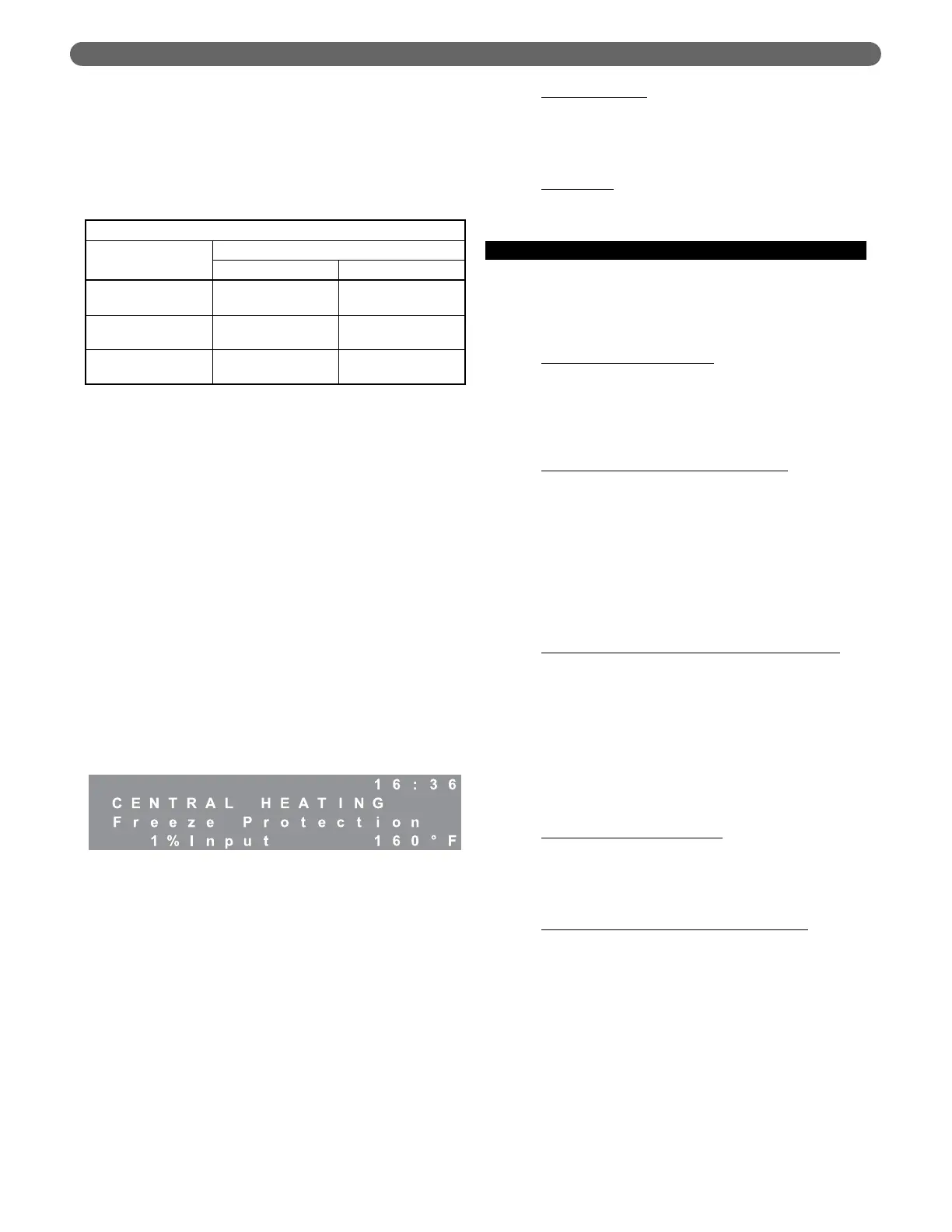

While this function is active the interface panel will

display the following:

4. Blower Postpurge Time:

The P

UREFIRE

®

boiler control allows the installer to

change the burner postpurge timing. This is useful

under extreme conditions where high winds and

unusual wind currents prevent proper purging of the

combustion chamber.

This parameter is adjustable from 30 seconds to 120

seconds with the 30 second minimum as its default. It

is important to note that increased purge times may

slightly reduce the boiler efficiency.

5. Additional Safety Functions:

The P

UREFIRE

®

boiler control is equipped with terminals

for either a low water cutoff or a flow switch. The low

water cutoff option is the factory default and a factory

supplied jumper is installed. This jumper is to be

removed if a low water cutoff or flow switch is installed.

Low Water Cutoff

: The installer can connect the

power supply wires for a probe-type low water cutoff

to terminal #19 (Hot) and #20 (Neutral) in the main

terminal box. The contacts should be wired to

terminals #9 and #10.

Flow Switch

: If a flow switch is used, simply wire the

contacts to terminals #9 and #10 in the main

terminal box.

D. CENTRAL HEATING

1. Heating Modes:

Table 8.1 provides an overview of the central heating

(CH) modes. The following are detailed descriptions

of the operation of these modes:

Mode 0 – Indoor Thermostat

: This is the default mode

for the control. When this mode is selected, the

control starts the boiler in response to a demand from

the indoor thermostat. The boiler will target the User

selected setpoint each time there is a heat demand. In

this case, the outdoor thermostat is not required.

Mode 1 – Thermostat and Outdoor Reset

: In this

mode, the control uses the outdoor temperature to

calculate a target for the boiler setpoint.

The installer selects design temperatures and mild

weather temperatures on the installer menu. The

control then calculates a target supply temperature

based on the current outdoor temperature.

A detailed explanation of Outdoor Reset is provided

in section 8.D.3.

Mode 2 – Permanent Demand and Outdoor Reset

:

In this mode, the boiler control operates on a

permanent demand independent of room thermostats.

The boiler is held at a target supply temperature

calculated using the current outdoor temperature. In

this mode, a contact closure across terminals #1 and

#2 (CH T’Stat) will result in an 18°F temperature

setback. This can be used in conjunction with a timer

or switch for night or unoccupied setback periods. A

detailed explanation of Outdoor Reset is provided in

section 8.D.3.

Mode 3 – Permanent Demand

: Mode 3 is similar to

Mode 2 except that the boiler target is a constant user

defined setpoint. Again, a contact closure across

terminals #1 and #2 (CH T’Stat) will result in an

18°F temperature setback.

Mode 4 – 0-10 V Input to Modulate Setpoint

:

This feature requires the use of the PFA-1 Interface

Adapter kit (54271). With this adapter, this mode

allows the boiler setpoint to be controlled by an

external source using a 0-10 VDC analog signal. An

input of 2 volts is required to activate the call for heat.

With an input voltage of 2 volts, the setpoint

temperature will be 50°F and an input of 10 volts

corresponds to a setpoint of 195°F. The setpoint is

proportional between these values.

This mode is commonly used in conjunction with a

Building Management System (BMS) to control the

boiler setpoint based on the building requirements.

BOILER CONTROL: INTERNAL WIRING & OPERATION

Table 8.6: Vent Temperature Limits

Vent Limit Temperature

Vent

Material

Location

U.S.A. Canada

PVC

190°F

(80°C)

149°F

(65°C)

CPVC

230°F

(110°C)

190°F

(80°C)

PP(s)

230°F

(110°C)

230°F

(110°C)

Loading...

Loading...