17

FUEL PIPING

5. Refer to table 5.4 for minimum supply pressure for

the purpose of input adjustment.

6. Install the boiler such that the gas ignition system

components are protected from water (dripping,

spraying, rain, etc.) during appliance operation and

service (circulator replacement, condensate trap

clean out, control replacement, etc.)

7. The boiler and its gas connection must be leak tested

before placing the boiler in operation.

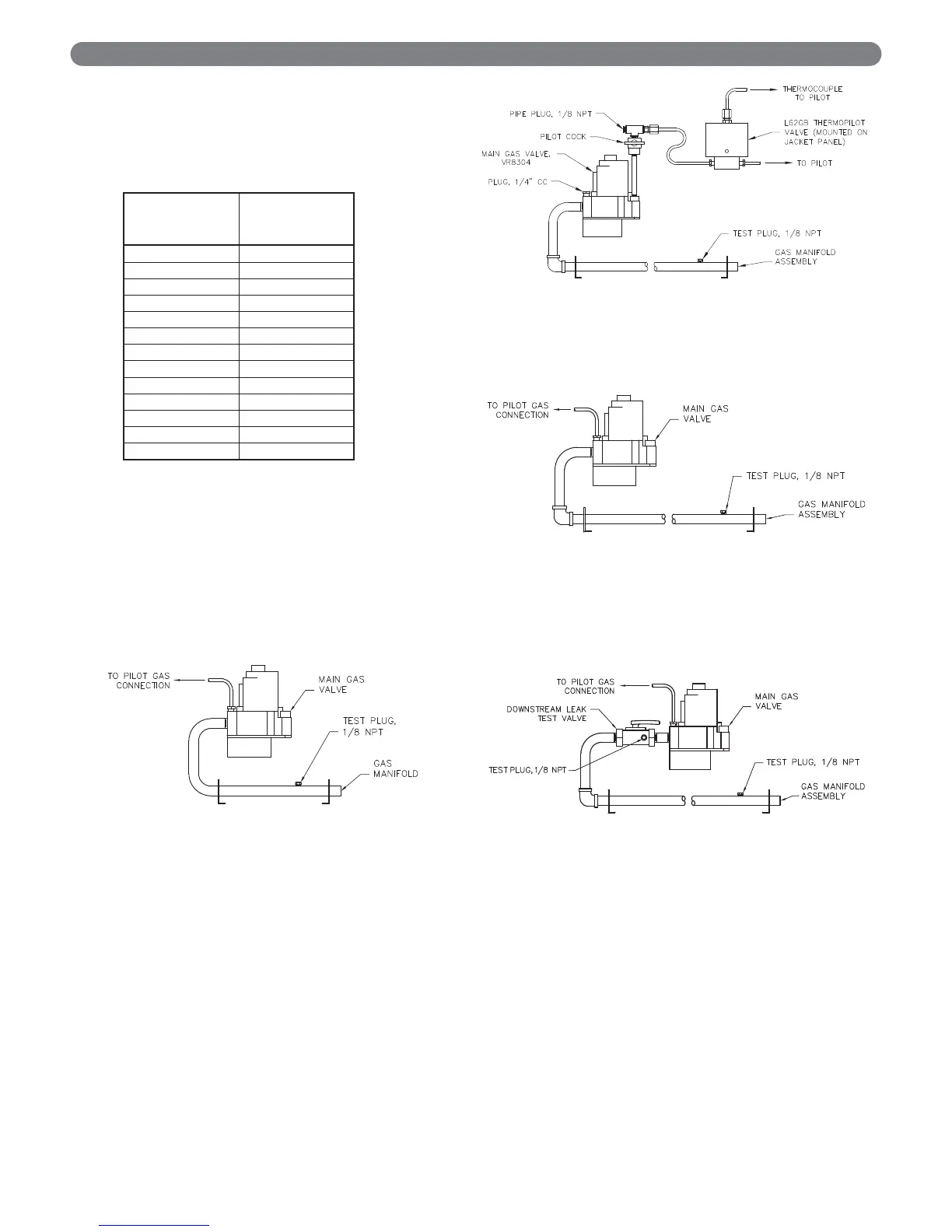

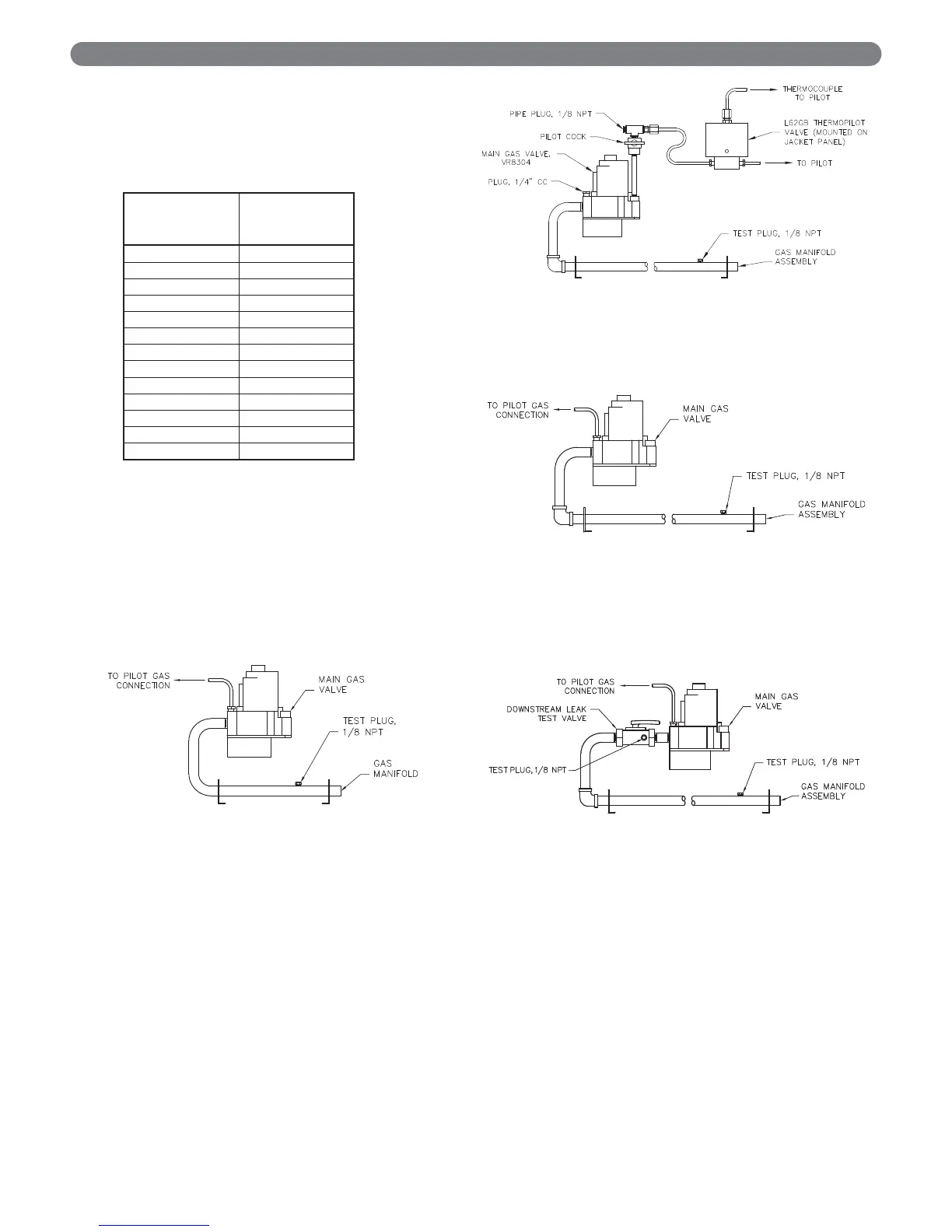

8. Typical gas train manifolds are illustrated in Figure

5.2 through 5.5.

Model

Supply

Pressure

(in. Water)

63-03L 5.00

63-03 5.00

63-04L 5.00

63-04 5.35

63-05L 5.00

63-05 5.00

63-06 5.56

64-07 5.00

64-08 5.27

64-09 5.00

64-10 5.00

64-11 5.00

64-12 5.10

Table 5.4: Minimum Supply

Pressure Natural Gas

Figure 5.2: Gas Train Manifold 63-03L

Through 63-06

Figure 5.5: Gas Train Manifold – Natural & LP Gas

64-09 Through 64-12

Figure 5.4: Gas Train Manifold – 64-07/08 LP Gas,

Standing Pilot & 64-07/08 Spark

Ignited Natural & LP Gas

Figure 5.3: Gas Train Manifold – 64-07 & 64-08

Natural Gas, Standing Pilot

Loading...

Loading...