Using the RS485 output to communicate

with BACnet

You can optionally connect the A525 Fermentation

Controller to a supervisory controller through a BACnet

MS/TP bus for remote monitoring and programmability

within a building automation system (BAS).

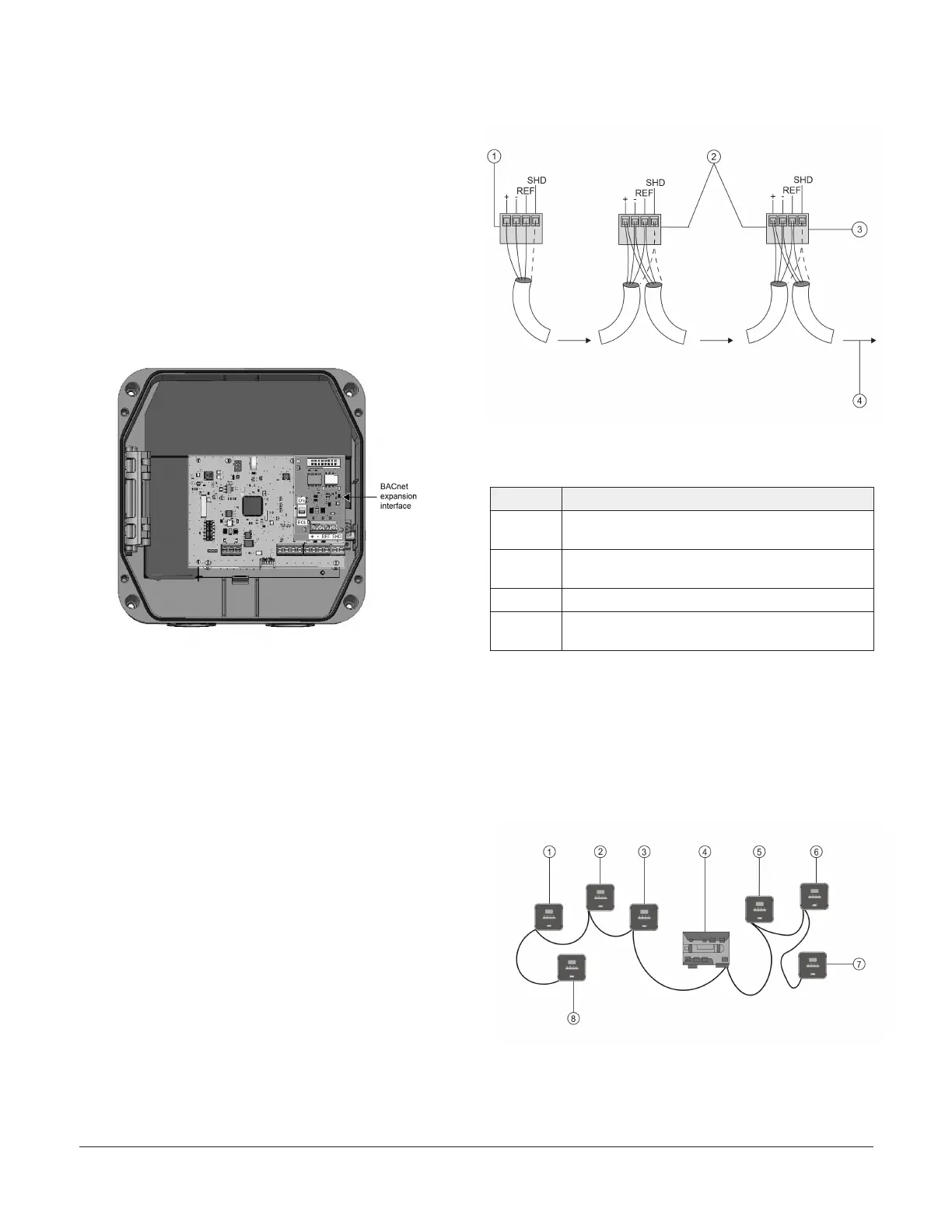

The A525 Fermentation Controller uses the isolated

RS485 output on the BACnet expansion interface to

communicate with BACnet. See the following figure for

an example of the BACnet expansion interface on the

controller.

Figure 6: BACnet expansion interface on the A525

Fermentation Controller

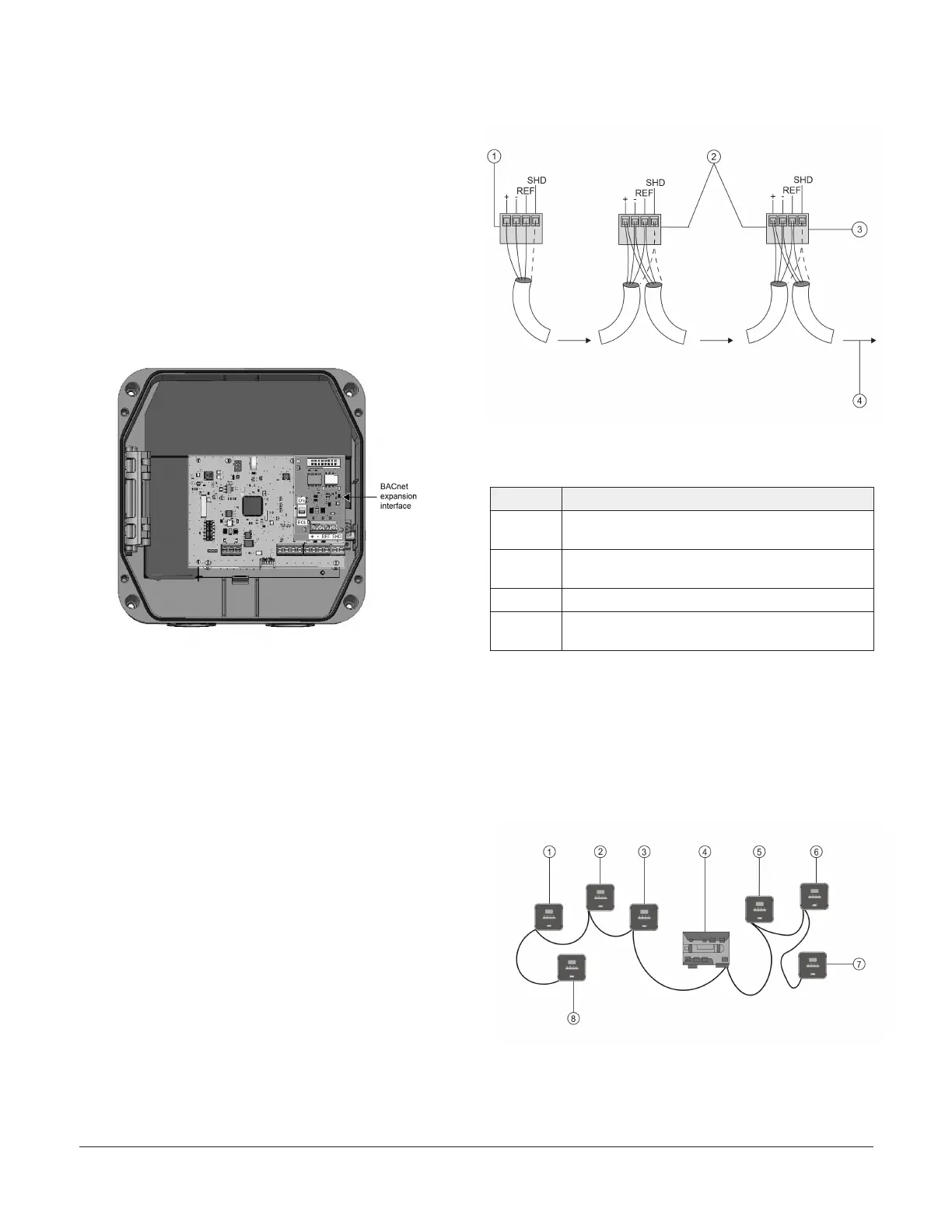

Connect the network terminal block on the A525

Fermentation Controller to the other devices in a daisy-

chain configuration using three-wire twisted, shielded

cable.

The isolated cable shield drain (SHD) terminal on the

network terminal block splices the cable shields along the

daisy-chain. See the following figure for more information

about daisy-chain configurations.

Figure 7: Network devices in a daisy-chain

configuration

Table 4: Network devices in a daisy-chain

configuration callout table

Callout Description

1

Terminating device on the RS485 network

trunk

2

Daisy-chained devices on the RS485 network

trunk

3 Isolated shield connection terminal

4

To the next device on the RS485 network

trunk

Set each network device that connects to the end of a

daisy-chain network trunk as a terminating device. The

A525 Fermentation Controller contains an end-of-line

(EOL) switch.

When you set the switch to on, the controller becomes

a terminating device. See the following figure for more

information.

Figure 8: EOL switch positions on network devices in a

daisy-chain network trunk

A525 Fermentation Tank Controller Installation Guide6

Loading...

Loading...