2 V46 Series 2-Way Pressure-Actuated Water-Regulating Valves With Union Fittings Installation Instructions

Table 1: V46 Valve Dimensions, inches (millimeters)

Code

Valve

V46AJ-2C 1/2 in. 3-1/2 (89) 1-13/16 (47) 6-3/8 (162) 3-3/4 (96)

2-5/8 (67)

3/4 in. 3-13/16 (97) 2 (52) 6-13/16 (173) 4-3/16 (106) 2-5/8 (67)

V46AL-2C 1 in. 5-1/8 (130)

2-5/8 (67)

9-11/16 (246) 5-15/16 (151) 3-3/4 (95)

V46AM-2C 1-1/4 in. 5-3/16 (131) 2-5/8 (67) 10-1/8 (260) 6-3/16 (160) 3-15/16 (100)

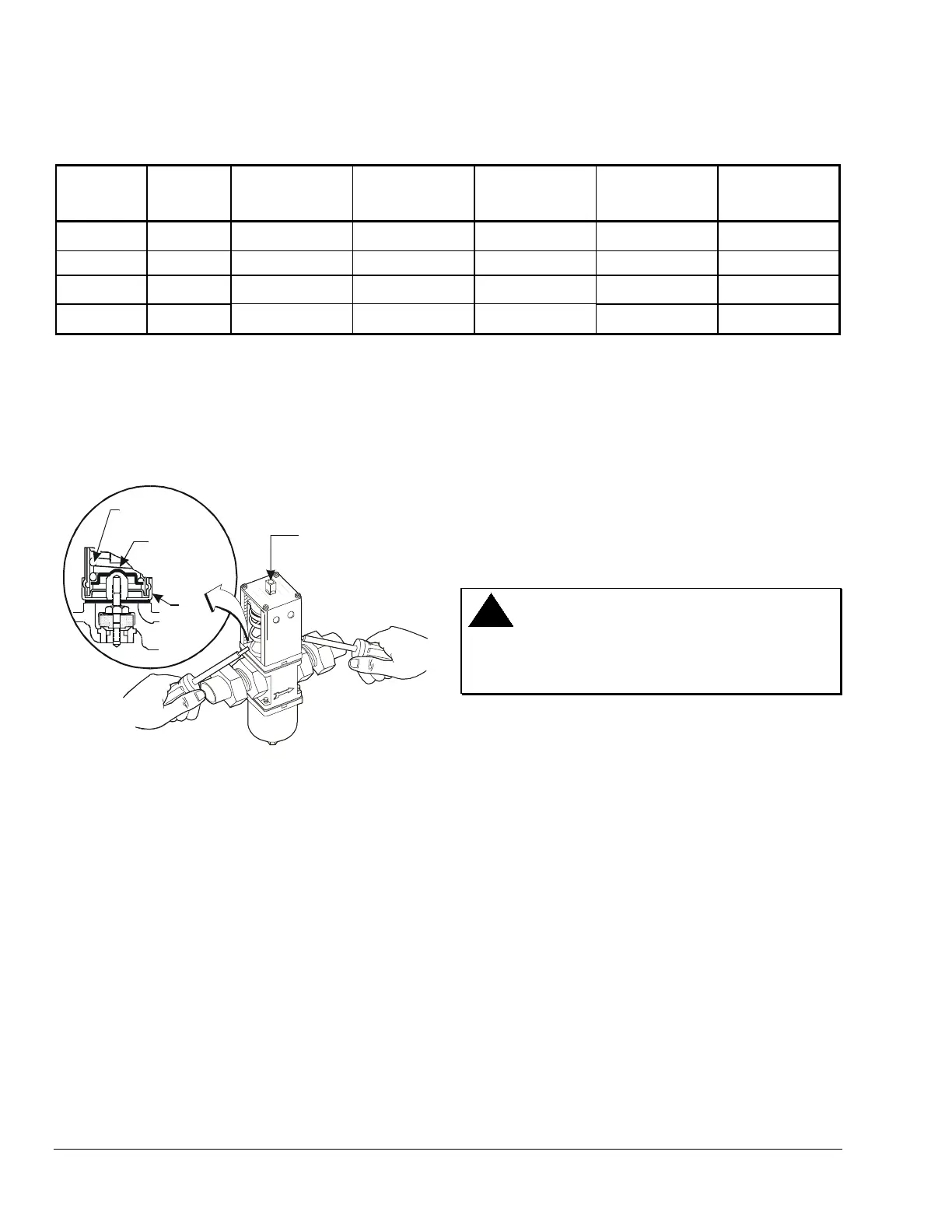

Manually Flushing the Valve

Manually flush the valve and fluid piping before and

after installing, repairing, or replacing a valve to

remove filings, chips, or other foreign matter. Insert

screwdrivers under both sides of the valve spring

guide and lift upwards to flush the valve. See Figure 2.

Manual flushing does not affect valve adjustment.

Range Adjustment

Screw

Range

Spring

Valve Spring

Guide

Top

Retainer

Insert screwdrivers

underneath the valve

spring guide.

Figure 2: Manual Flushing

V46_union_flush.cdr

Location Considerations

Install the valve vertically with the range adjustment

screw on the top and the bellows and pressure

connection line on the bottom to allow drainage of oil

and refrigerant away from the valve bellows.

Do not mount the valve in any position other than

vertical unless specified by the manufacturer of the

equipment on which the valve is installed. Follow the

manufacturer’s installation instructions.

Install the valve on the inlet side of the condenser. If it

is necessary to keep the condenser flooded with

water, install the valve on the outlet side of the

condenser.

If the system is located in an area with high ambient

temperatures, refrigerant head pressures may remain

high enough during off cycles to prevent the valve from

closing completely. In such instances, raise the

opening point of the valve just enough to cause the

valve to close flow to the condenser during

compressor standby periods.

Pressure Connections

WARNING: Risk of Personal Injury.

To avoid possible personal injury, shut off the liquid

supply and relieve the pressure before servicing the

valve.

Connect the refrigerant-side flare connector to the

appropriate high-side pressure tap point. If additional

capillary tubing is necessary, use 1/4-in. tradesize

copper tubing.

Follow the guidelines below when making pressure

connections:

• Use Pressure Tap Points Located on the Top

Side of the Refrigerant Lines

This reduces the possibility of oil, liquids, or

sediment accumulating in the pressure connection

line or valve bellows, which could cause valve

malfunction.

• Avoid Sharp Bends in the Capillary Tubes

Sharp bends can weaken or kink capillary tubes,

which may result in refrigerant leaks or

restrictions.

• Allow for Slack in the Capillary Tubes to

Dampen Vibration

Mechanical vibration can weaken or damage the

capillary tubes.

Loading...

Loading...