WARNING: If control is wired to a transformer, do not switch the primary side of transformer to disconnect power or catastrophic

failure can result. Always disconnect control from secondary side of transformer.

CAUTION: Do not bundle potentiometer connections (P1, P2, P3) and Inhibit™ connections (I1, I2) with AC line or motor wires.

WARNING: Armature Switching. Do not switch the armature in and out of circuit or catastrophic failure will result. If armature

switching is required for dynamic brake or reversing, use model KBRG, KBPB or KBCC-R suffix controls.

NOTE: (Shunt motors only) For 90V DC motors with 50VDC fields and 180VDC motors with 100VDC fields, use half voltage

field connections F+ and L1. (See table 7, p. 8)

C. Voltage Following – All models can be controlled with an isolated analog reference voltage (0-7 VDC) in lieu of the main

speed potentiometer. The voltage is connected to P2 (+) and F-. The control output voltage will linearly follow the input voltage.

The source impedance of the input should be 10K ohms or less. The Min and Max trimpots are rendered inoperative in the

voltage following mode. Use auxiliary trimpots for scaling and to limit the control range. If the input signal is not isolated, or

is a current signal (4 - 20 mA), the KBSI-240D or SI-5 Barrier Terminal Board Signal Isolator must be used. It will allow direct

connection to process controllers and microprocessors.

CAUTION:

1. The voltage feeding P2 and F- must be isolated from the AC line. Do not earth ground P2 or F- to setup a zero or ground

reference.

2. Do not bundle signal wires to P2 and F- with AC line or motor connections. If signal wires are over 18 inches, use shielded

cables.

D. Fusing – The KBIC

®

has provision for adding a built-in AC line fuse and armature fuse*. The AC line fuse protects the control

against catastrophic failure. If the fuse blows, the control is miswired, the motor is shorted or grounded, or the KBIC

®

control

is defective. The armature fuse provides overload protection for the motor and control. Choose the proper size armature fuse

and AC line fuse (see fuse chart table 4, p. 5) by multiplying the maximum DC motor amps by 1.7. Armature and AC line fuse

kits are available from your distributor. On domestic 230 Volt AC lines, separate branch circuit protection for each line must

be used. All fuses should be normal blow ceramic 3AG or MDA or equivalent. The Barrier Terminal Kit (optional) contains

prewired AC line and armature fuses. *Contact your distributor.

9

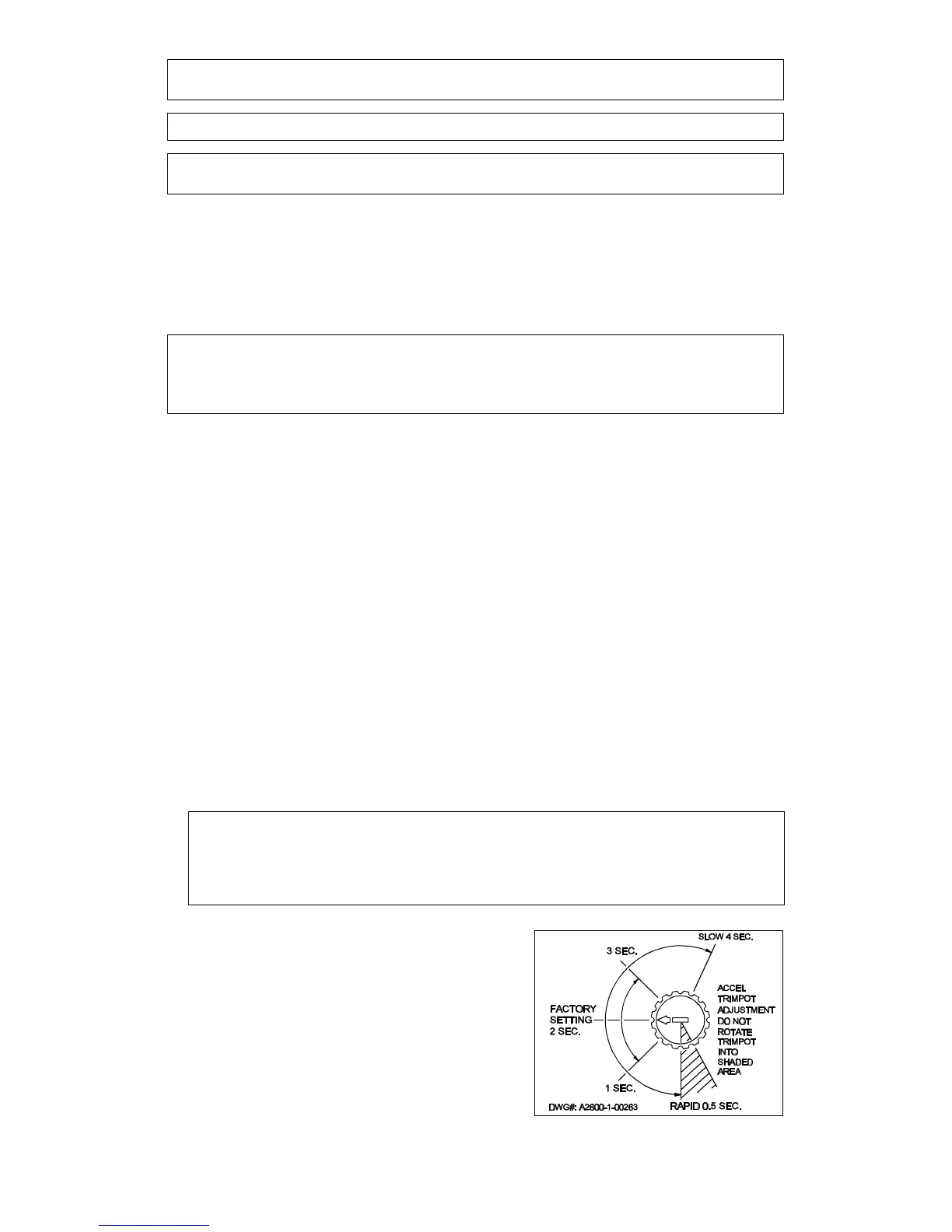

FIG. 4 – ACCEL TRIMPOT ADJUSTMENT

III. ADJUSTMENTS AND CONTROL FUNCTIONS

The KBIC

®

is factory adjusted to provide 0 to full speed range using a 5K potentiometer. Minimum and maximum speed trimpots

are provided to change the speed range from other than 0 to full speed. An acceleration start (located directly behind the MIN

trimpot) is factory set to provide motor acceleration from 0 to full speed over a time period of 2 seconds (approx.) each time the

AC power is applied. The current limiting (CL, or torque output) adjustment is factory set to approximately one and a half times

the motor rating. The IR Compensation (IR) is factory adjusted to provide excellent motor regulation under normal operation.

NOTE: In order for the IR comp and CL trimpot settings to be correct, the proper Plug-in Horsepower Resistor

®

must be

installed for the particular motor and input voltage being used. Do not attempt to change the settings of the trimpots

unless absolutely necessary since they are factory adjusted to near optimum settings.

IMPORTANT NOTE:

Readjusting the ACCEL time will affect the MAX speed and IR Comp. settings which will have to be readjusted (see

this Section). If the ACCEL time is decreased to the minimum time of 0.5 seconds (6 o'clock trimpot position), then

increase the IR trimpot 25% CW rotation and decrease the MAX trimpot 20% CCW rotation. If the ACCEL time is

increased to the maximum time of 4 seconds (full rotation), then decrease the IR and increase the MAX as per

above percentages of rotation.

The following procedure is presented in required order of adjustment.

It should be followed when readjusting all trimpot functions:

A. Acceleration Start – (ACCEL trimpot is located directly behind the

MIN trimpot.) If the ACCEL is to be readjusted to different times,

adjust the trimpot to the desired time according to fig. 4.

B. Maximum Speed Adjustment – Set main speed pot to full speed

(maximum CW position). Adjust MAX speed trimpot to new desired

setting.

Note: Do not attempt to adjust the MAX speed above the rated motor

RPM since unstable motor operation may occur. For moderate

changes in the MAX speed, there will be a slight effect on the

MIN speed setting when the MIN speed is set at zero. There

may be significant variation in the MIN speed setting if the MIN

speed is at a higher than zero setting.

C. Minimum Speed Adjustment – If a higher than zero speed is desired, readjust the minimum speed by turning the main

speed potentiometer to zero setting (full CCW position). Then adjust the MIN speed trimpot to the desired setting.

10

Loading...

Loading...