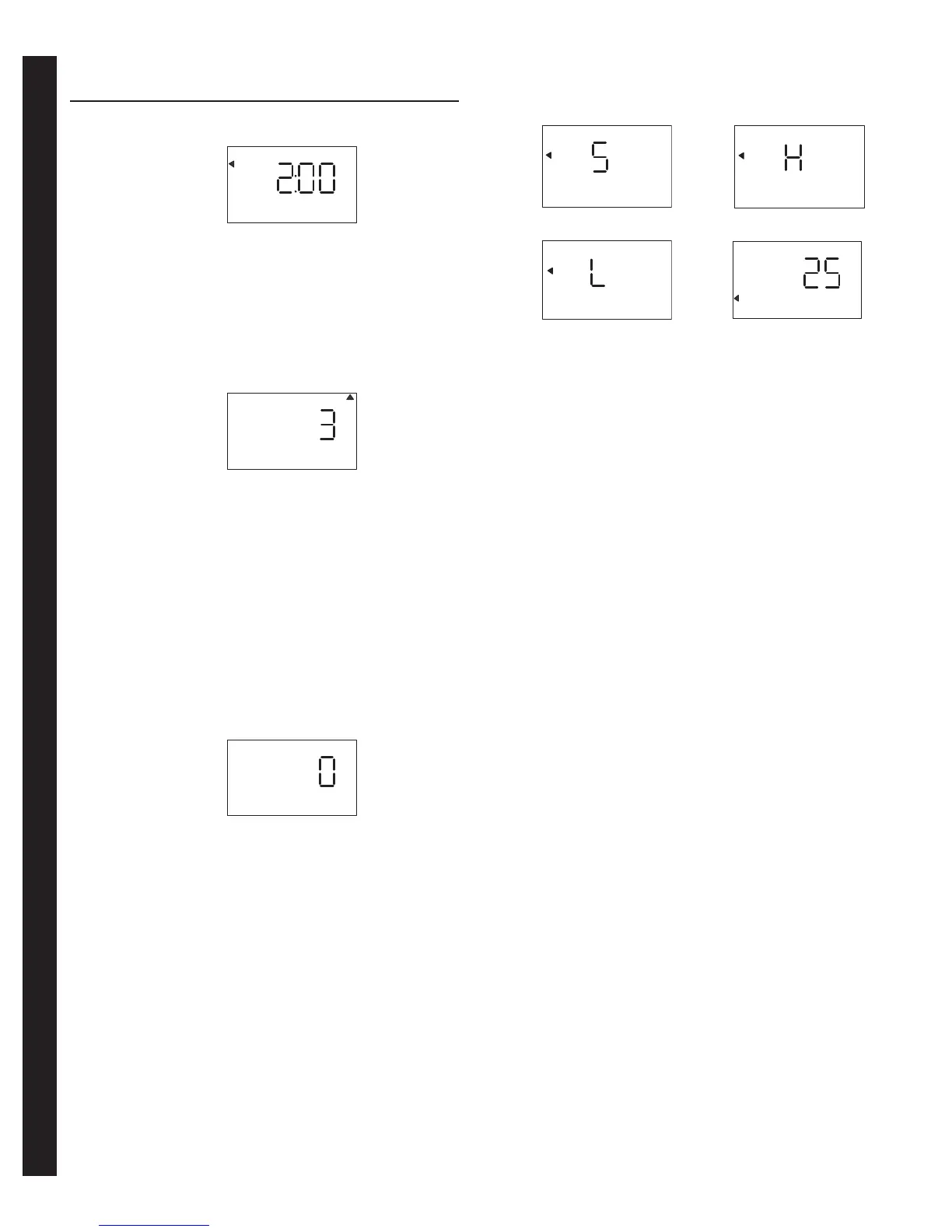

Step 4: Set Regen Time

Time & Day

Time & Day

Salt

SU MO TU WE TH FR SA DAYS

Capacity

Hardness

• 2:00 (AM) is the default time of regeneration. To accept

this time, press the DOWN button to move to step 5.

• To change the regen time, press SET - causing 2:00 to flash.

• Use the UP and DOWN buttons to advance to the desired

regen time.

• Press SET to accept the time and advance to the

next parameter.

Step 5: Set Days to Regenerate (740 Time-clock Control Only)

Time & Day

Time & Day

Salt

SU MO TU WE TH FR SA DAYS

Capacity

Hardness

• If using 760 control - proceed to step 5a.

• Set number of days between time-clock regeneration

(regen frequency).

• Default time is 3 days.

• Days can be adjusted from 1/2 (.5) to 99 days.

• To change, press SET to make the "3" flash.

• Use the UP and DOWN buttons to change to the number

of days desired.

• Press SET to accept the regen frequency, and advance to

the next cycle.

To use the 7-day timer option - see full Dealer

Installation Manual.

Step 5a: Set Calendar Override (760 Demand Control Only)

Time & Day

Time & Day

Salt

SU MO TU WE TH FR SA DAYS

Capacity

Hardness

• If using 740 control - proceed to step 7.

• Set number of days for calendar override on

demand control.

• "0" days is the default for calendar override.

• Days can be adjusted from 1/2 (.5) to 99 days.

• To change, press SET to make the "0" flash.

• Use the UP or DOWN buttons to change to the number of

days desired.

• Press SET to accept the regen frequency, and advance to

the next cycle.

LOGIX™ SERIES INSTALLER

QUICKSTART SHEET CONTINUED

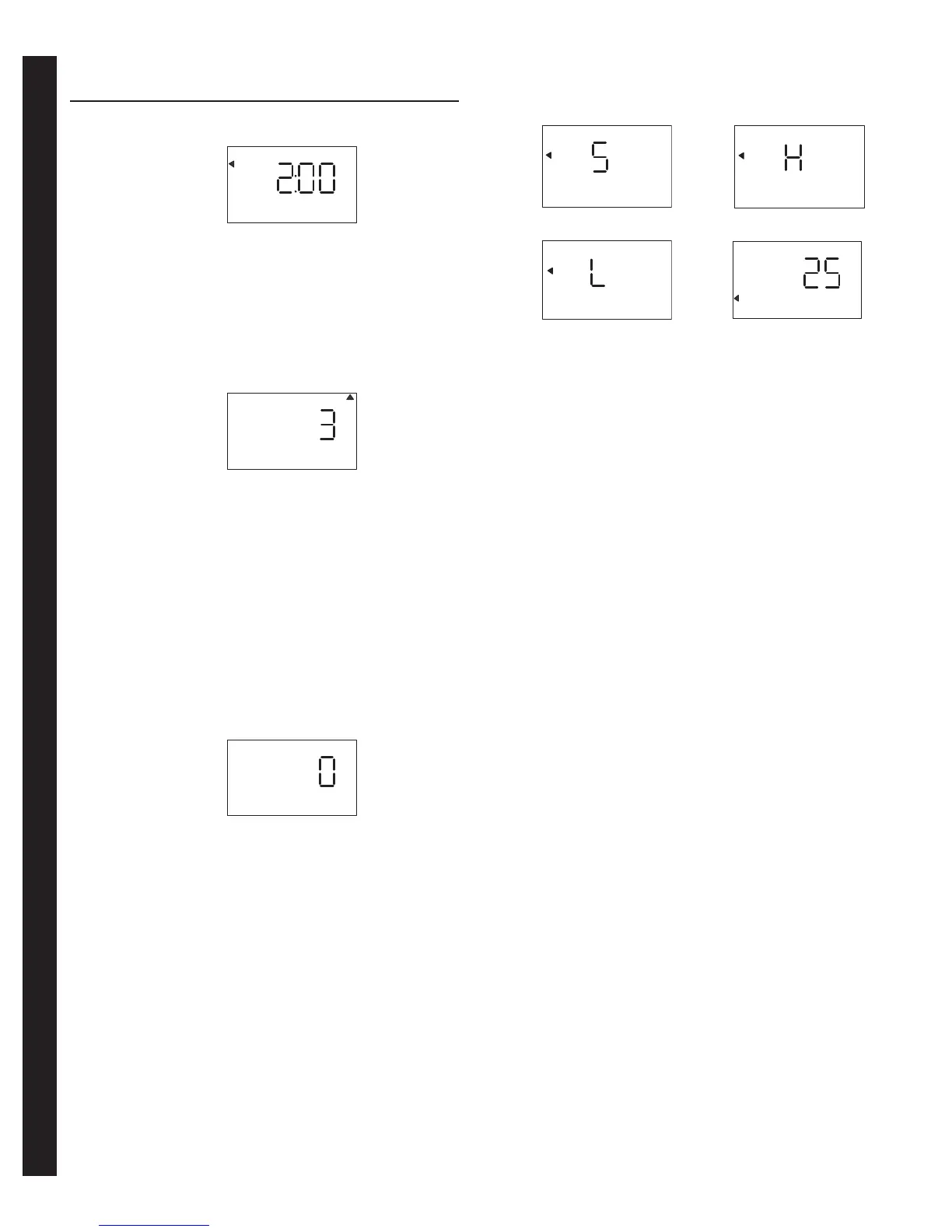

Step 6: Amount of Regenerant used per Regeneration

Time & Day

Time & Day

Salt Amount

SU MO TU WE TH FR SA DAYS

Capacity

Hardness

Time & Day

Time & Day

Salt Amount

SU MO TU WE TH FR SA DAYS

Capacity

Hardness

Standard Setting High Capacity Setting

Time & Day

Time & Day

Salt Amount

SU MO TU WE TH FR SA DAYS

Capacity

Hardness

KG

Time & Day

Time & Day

Salt

SU MO TU WE TH FR SA DAYS

Capacity

Hardness

Low Setting (High Efficiency)

• Set desired regenerant amount.

• Default setting is "S" standard salting.

• 3 salt settings are available on 740 and 760 controls:

S – Standard Salt – 9 lbs/cubic foot of resin (120 grams/

liter of resin)

H – High Salt – 15 lbs/cubic foot of resin (200 grams/liter

of resin)

L – Low Salt – 3 lbs/cubic foot of resin (40 grams/liter

of resin)

• Low Salt is the "Highly Efficient Mode".

• To change salt setting, press the SET button and use the

UP and DOWN buttons to change to the desired setting.

• Press SET to accept the setting and advance to the

next parameter.

See Dealer Installation Manual for more complete information

on :salt settings for different system sizes, capacities and

expected efficiencies.

Step 7: Estimated Capacity

• System capacity is displayed in total kilograins or kilograms

of hardness removed before a regeneration is necessary.

• Value is derived from the system’s resin volume input,

and salt amount input.

• The capacity displayed is a suggested value - as

recommended by resin manufacturers.

• Capacity is only displayed for information purposes on

740 control - it does not (and cannot) need to be changed.

• To change capacity on 760 control, press SET to make the

default capacity flash. Use the UP and DOWN buttons to

increment to the desired capacity.

• Press SET to accept the setting and advance to the

next parameter.

If using 740 control, programming is complete. The control will

return you to the normal operation mode.

Step 8: Enter Hardness (760 Demand Control Only)

• Enter inlet water hardness at installation site.

• Default hardness setting is 25 grains (25 ppm for metric).

• To change hardness, press SET to make the setting flash.

Use the UP and DOWN buttons to scroll to the

correct hardness.

• Press SET to accept the entered hardness value.

• The control will return you to the normal operation mode

Initial system programming is now complete. The control will

return to normal operation mode, if a button is not pushed for

30 seconds.

4 •AUTOTROL

®

740/760 Control 255 & Performa Series Valves (268, 268FA) Service Manual

QUICK START

Loading...

Loading...