Description 5

Transducer

The PENTEK

INTELLIDRIVE uses a 4-20mA, 0-668

kPa pressure transducer to control motor speed

(max is 2068 kPa transducer).

The transducer (see Figure 1) senses pressure

in the pipe and converts it to an electrical signal.

The Drive senses and processes the signal in the

PID (Proportional, Integration, Derivative) control.

When operating in AUTOSTART mode, the Drive

increases and decreases the speed of the pump

motor as needed to maintain constant pressure in

the piping system.

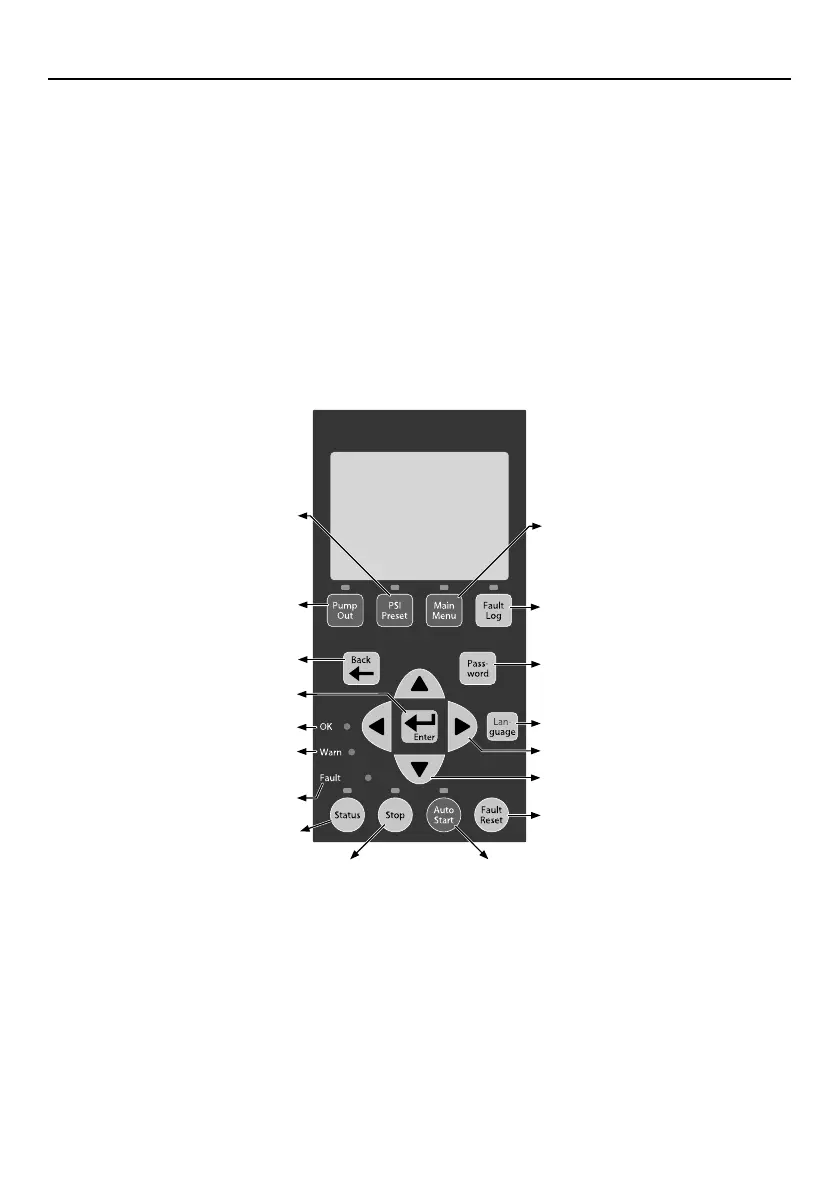

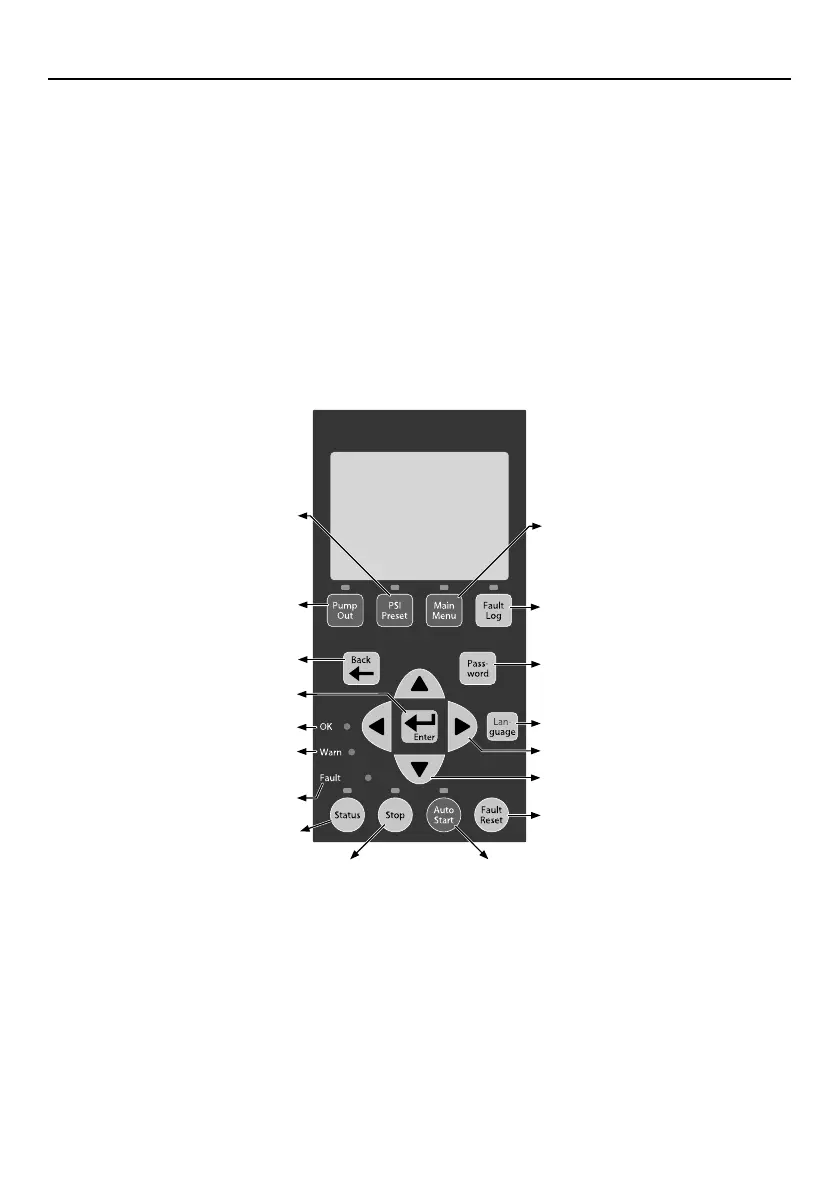

Keypad

The keypad programs the Drive, monitors the

status of the pump, and displays faults if they

occur. Each button has a unique function, as

described in Figure 2. The LCD display shows a

text display of the status of the Drive’s operation.

Other LEDs light up to indicate when certain

buttons are pressed or certain events occur.

Fan

The Drive uses a thermostatically controlled

internal fan which operates automatically when

necessary to cool the Drive components.

Figure 2 - PENTEK INTELLIDRIVE keypad functions

Stops the

motor.

Power is ON to Drive.

A fault has

occurred.

Selects menu items and confirms

numeric value changes.

Displays Drive’s current operating

condition and changes display

parameters.

Changes display to previous screen.

Drive is in Warning Mode (TPM); refer to

Troubleshooting section.

Changes internal pressure setpoint

from 103 kPa to transducer max

-20 kPa . ie 2047kPa

Runs the Drive at 45Hz (with no

pressure control) to allow installer to

pump out well.*

Up and down arrows scroll through

menus and change numeric values.

Toggles between English, Spanish, and

French (default is English).

Resets fault that stopped Drive/pump.

With code, locks and unlocks password

protected keys.

Left and right arrows move cursor.

Shows last 15 faults.

Checks for line fill, then starts pump

in constant pressure mode.

Views and changes

parameters.

PID_OM_2014.indd 5 24/02/2014 1:49:53 PM

Loading...

Loading...