5

1. To set the tool to desired torque, select a nut or screw of known tightness of the same

size, thread pitch and thread condition as those on the job.

2. Turn air regulator to low position, apply wrench to nut and gradually increase power (turn

regulator to admit more air) until nut moves slightly in the direction it was originally set.

The tool is now set to duplicate that tightness, note regulator setting for future use.

3. When tightening nuts not requiring critical torque values, run nut up flush and then

tighten an additional one quarter to one-half turn (slight

additional turning is necessary if

gasket are being clamped).

4. For additional power needed on

disassembly work, turn regulator to its

fully open position. This impact wrench

is rated at 5/8 USS bolt size. Rating

must be down graded for spring U bolts,

tie bolts, long cap screws, double depth

nuts, badly rusted conditions and spring

fasteners as they absorb much of the

impact power. When possible, clamp or

wedge the bolt to prevent spring back.

5. Soak rusted nuts in penetrating oil and

break rust seal before removing with

impact wrench. If nut does not start to move

in three to five seconds use a larger size

impact wrench. Do not use impact wrench

beyond rated capacity as this will drastically

reduce tool life.

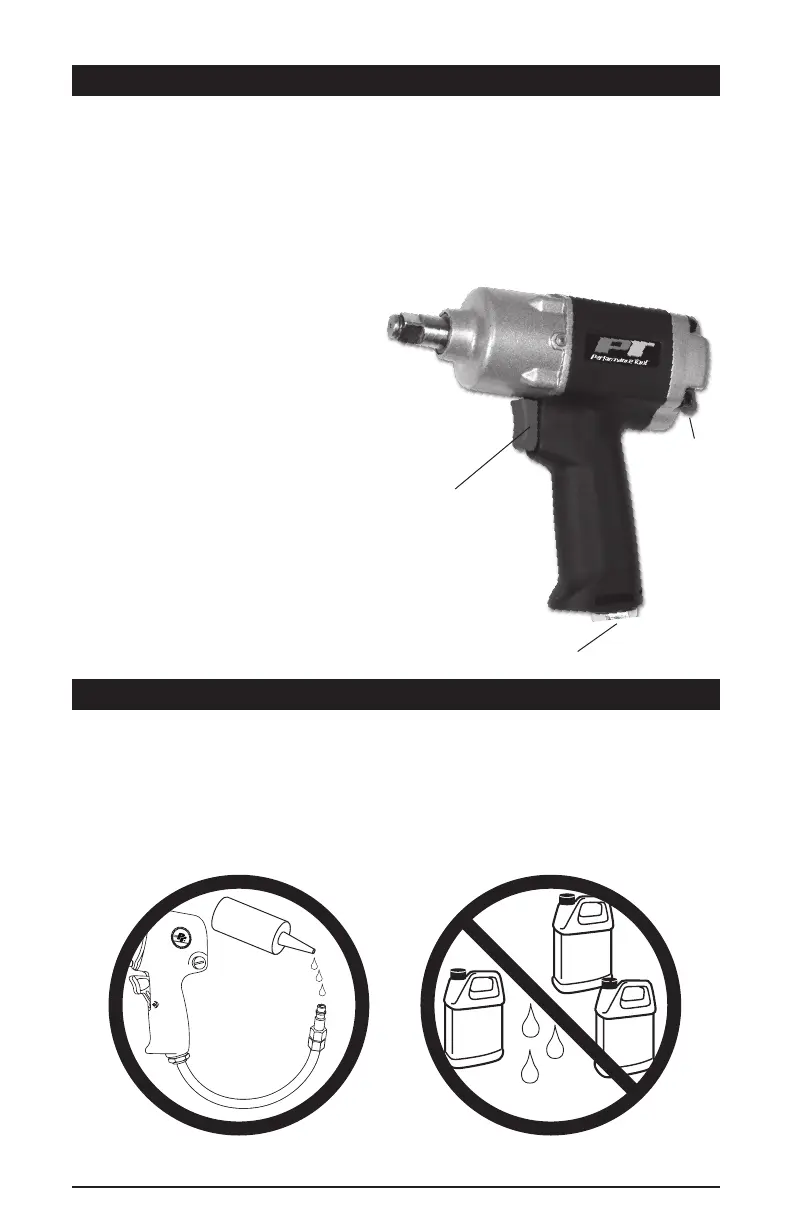

Oil tool before each use. 4 to 5 drops of a good grade Air Tool Oil placed in the air inlet is

sufficient. Use proper air pressure and CFM rating listed for this tool.

Drain water from hoses and compressor tank. Water in the air supply line will cause

gumming and loss of power. Clean the air filter on the supply line and flush the tool with

gum solvent or a 50/50 mix of air tool oil and kerosene. It may be necessary to

disassemble the tool to properly clean and re-lubricate.

LUBRICATION & MAINTENANCE

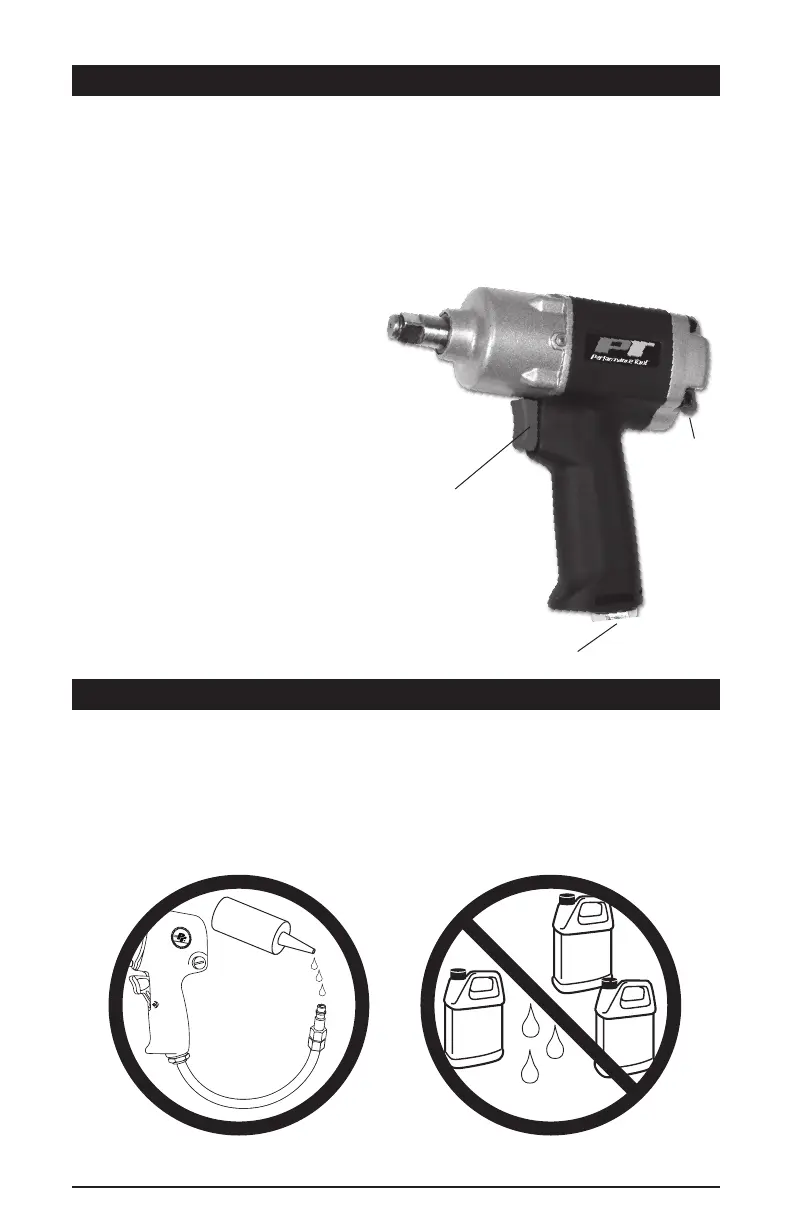

Motor

Oil

Trans.

Fluid

Brake

Fluid

Water

Whip

hose

Air Tool

Oil

OPERATION

Air Inlet

Air

Regulator

Trigger

Loading...

Loading...