Engines Operating on B20 Biodiesel

Refer to this Manual Fluid Recommendations, “Fuel

Specification” for the required service interval for

operating with B20.

Engines Operating on High Sulfur Fuel

Refer to this Manual Fluid Recommendations, “Fuel

Specification” for the required service interval for

operating with high sulfur fuel.

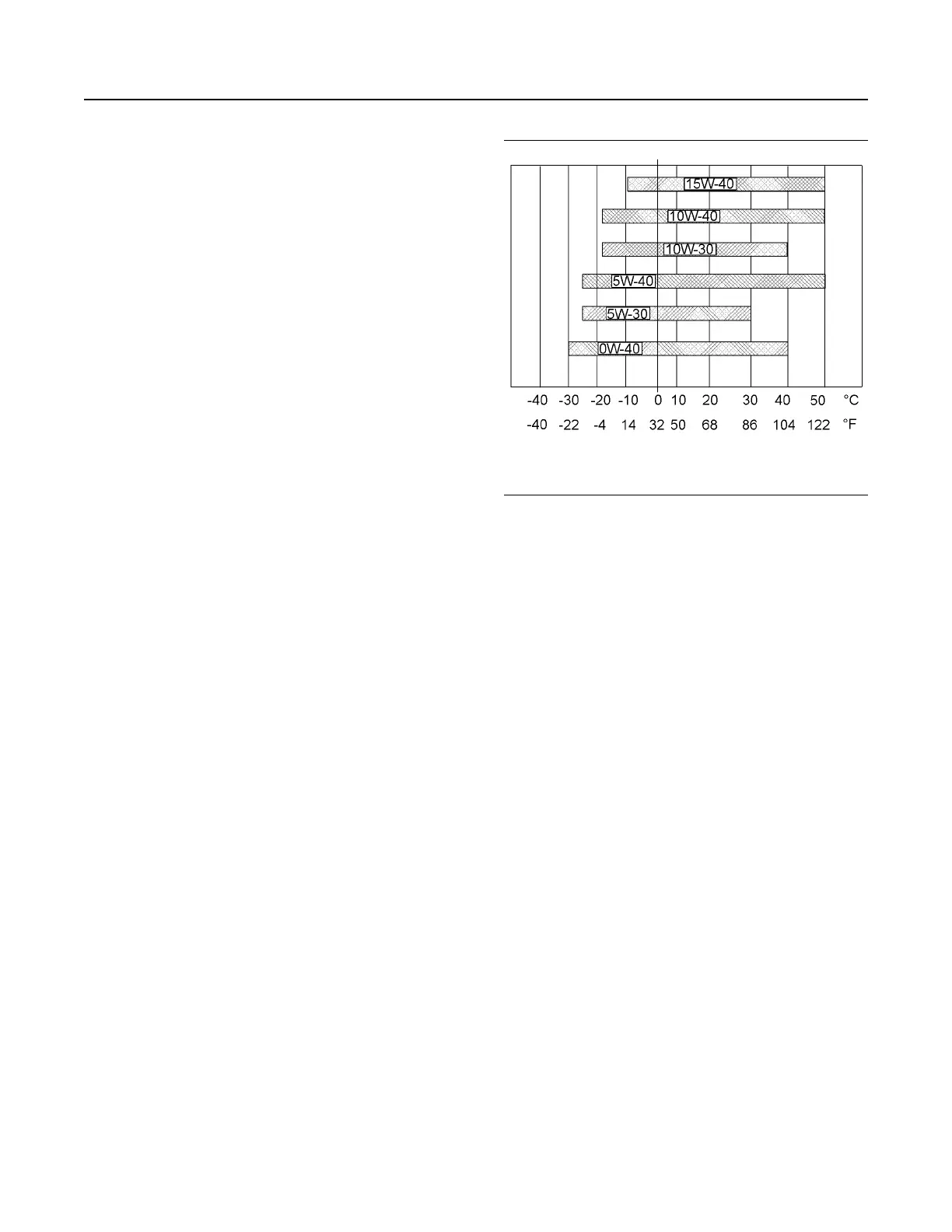

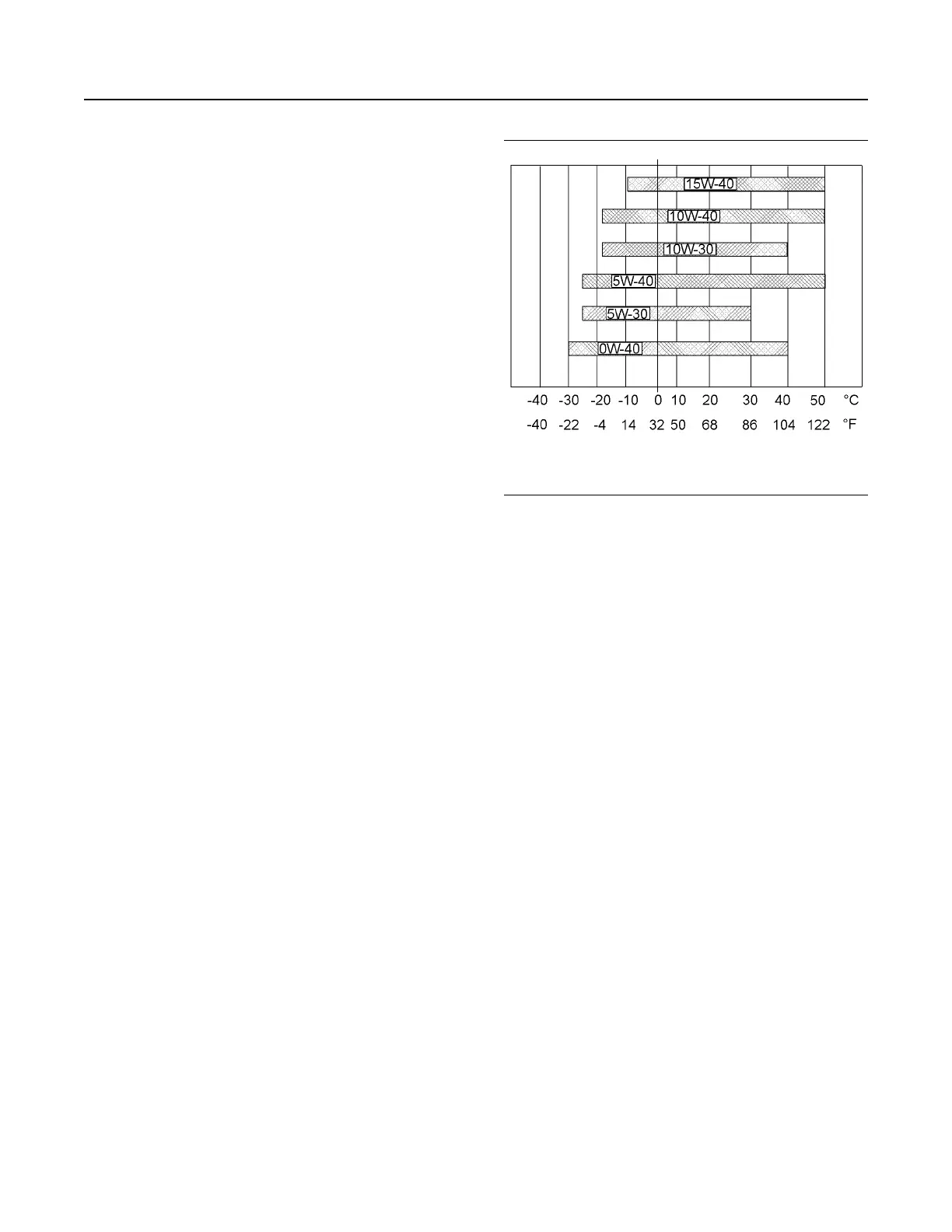

Lubricant Viscosity Recommendations

for Direct Injection (DI) Diesel Engines

The correct SAE viscosity grade of oil is determined

by the minimum ambient temperature during cold

engine start-up, and the maximum ambient

temperature during engine operation.

Refer to illustration 33 (minimum temperature) in

order to determine the required oil viscosity for

starting a cold engine.

Refer to illustration 33 (maximum temperature) in

order to select the oil viscosity for engine operation at

the highest ambient temperature that is anticipated.

Generally, use the highest oil viscosity that is

available to meet the requirement for the temperature

at start-up.

Illustration 33 g03347115

Lubricant Viscosities

Supplemental heat is recommended for cold soaked

starts below the minimum ambient temperature.

Supplemental heat may be required for cold soaked

starts that are above the minimum temperature that

is stated, depending on the parasitic load and other

factors. Cold soaked starts occur when the engine

has not been operated for a period of time. This

interval will allow the oil to become more viscous due

to cooler ambient temperatures.

Aftermarket Oil Additives

Perkins does not recommend the use of aftermarket

additives in oil. It is not necessary to use aftermarket

additives in order to achieve the engines maximum

service life or rated performance. Fully formulated,

finished oils consist of base oils and of commercial

additive packages. These additive packages are

blended into the base oils at precise percentages in

order to help provide finished oils with performance

characteristics that meet industry standards.

There are no industry standard tests that evaluate

the performance or the compatibility of aftermarket

additives in finished oil. Aftermarket additives may

not be compatible with the finished oils additive

package, which could lower the performance of the

finished oil. The aftermarket additive could fail to mix

with the finished oil. This failure could produce sludge

in the crankcase. Perkins discourages the use of

aftermarket additives in finished oils.

To achieve the best performance from a Perkins

engine, conform to the following guidelines:

• See the appropriate “Lubricant Viscosities”. Refer

to the illustration 33 in order to find the correct oil

viscosity grade for your engine.

SEBU8731-04

63

Maintenance Section

Engine Oil Specification

Loading...

Loading...