Dual Element Air Cleaners

The dual element air cleaner contains a primary air

cleaner element and a secondary air cleaner

element. The primary air cleaner element can be

used up to six times if the element has been properly

cleaned and inspected. The primary air cleaner

element should be replaced at least one time per

year. This replacement should be performed

regardless of the number of cleanings.

The secondary air cleaner element is not serviceable

or washable. The secondary air cleaner element

should be removed and discarded for every three

cleanings of the primary air cleaner element. When

the engine is operating in environments that are

dusty or dirty, air cleaner elements may require more

frequent replacement.

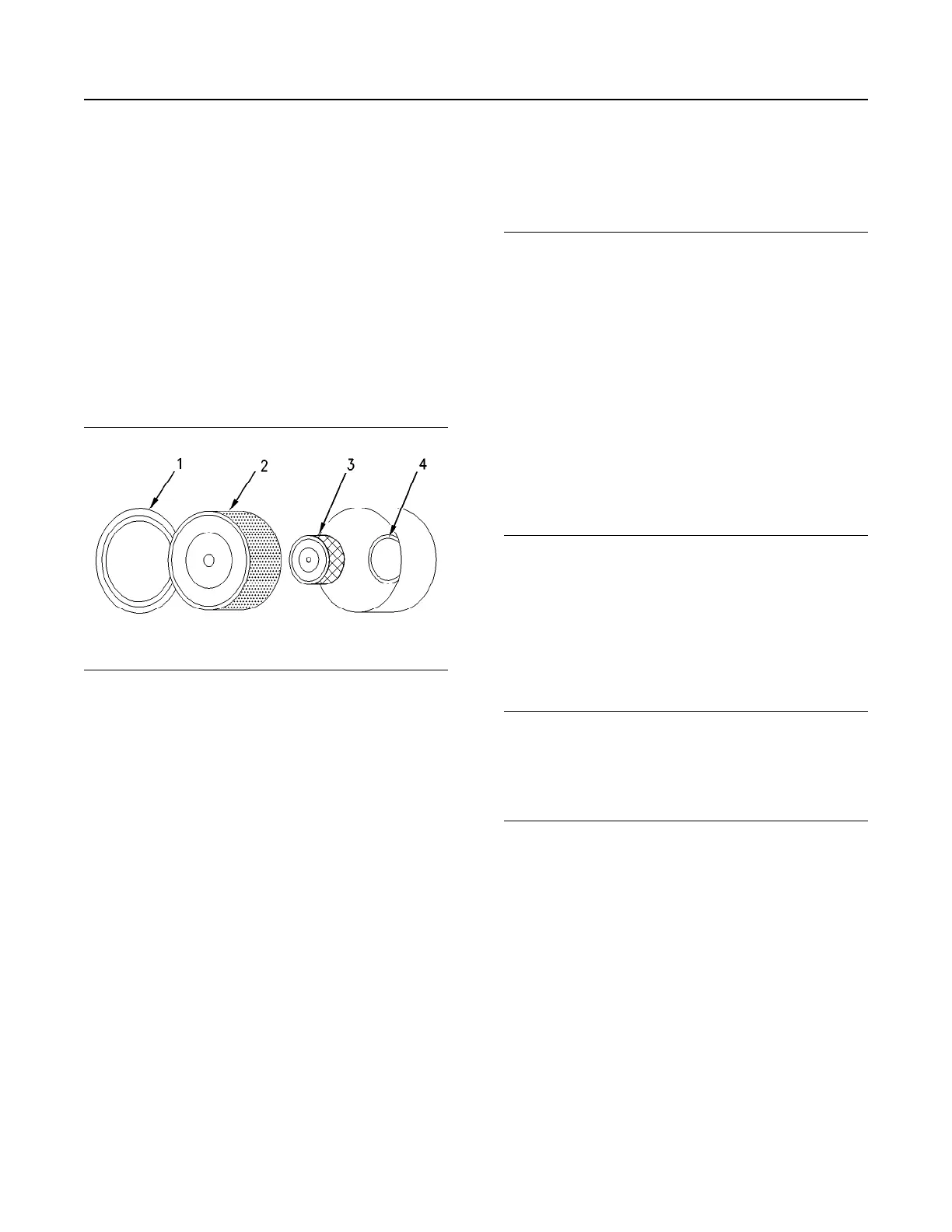

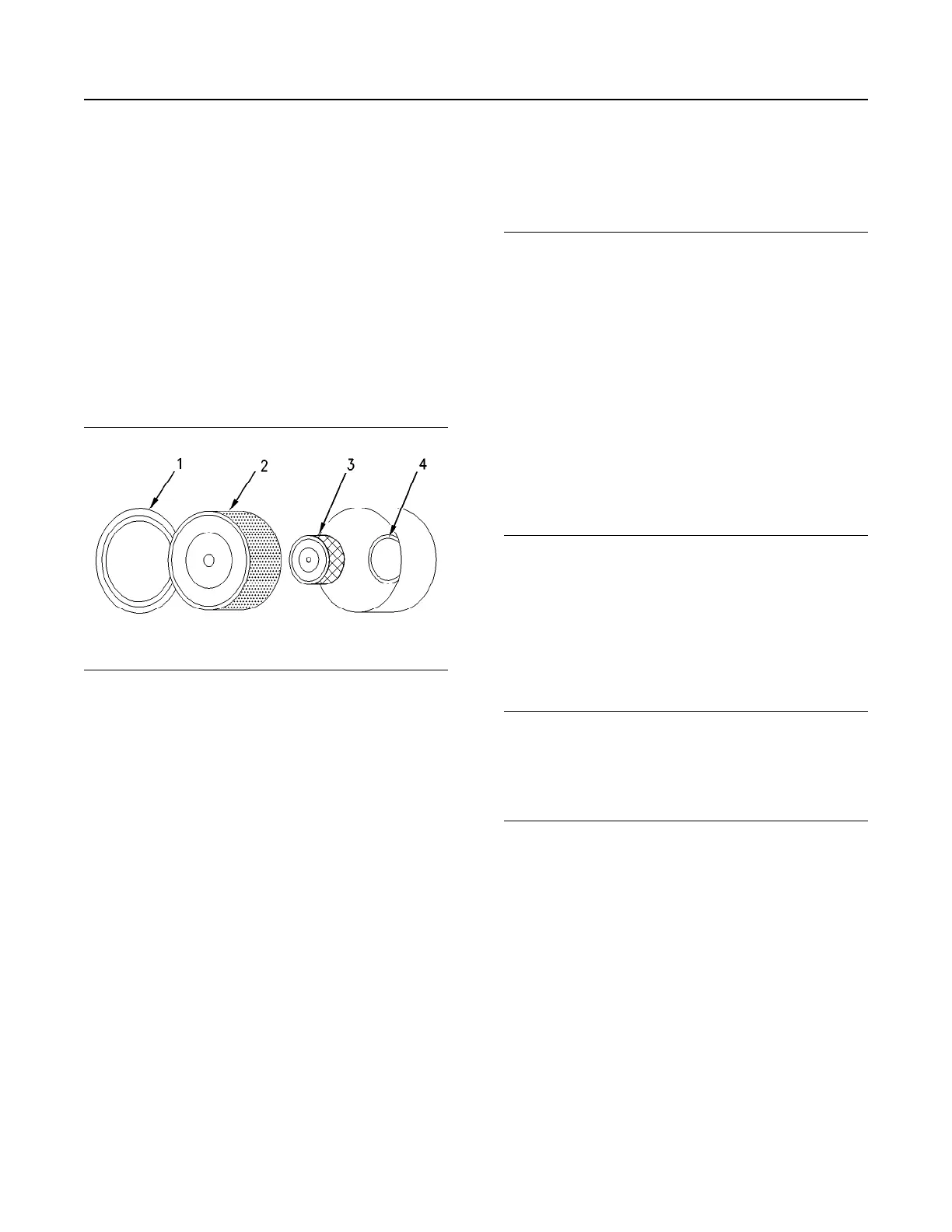

Illustration 41 g00736431

(1) Cover

(2) Primary air cleaner element

(3) Secondary air cleaner element

(4) Air inlet for the turbocharger

1. Remove the cover. Remove the primary air cleaner

element.

2. The secondary air cleaner element should be

removed and discarded for every three cleanings

of the primary air cleaner element.

Note: Refer to “Cleaning the Primary Air Cleaner

Elements”.

3. Cover the air inlet to the turbocharger with tape in

order to keep out dirt.

4. Clean the inside of the air cleaner cover and body

with a clean, dry cloth.

5. Remove the tape from the air inlet of the

turbocharger. Install the secondary air cleaner

element. Install a primary air cleaner element that

is new or cleaned.

6. Install the air cleaner cover.

7. Reset the air cleaner service indicator.

Cleaning the Primary Air Cleaner

Elements

NOTICE

Observe the following guidelines if you attempt to

clean the filter element:

Do not tap or strike the filter element in order to re-

move dust.

Do not wash the filter element.

Use low pressure compressed air in order to remove

the dust from the filter element. Air pressure must not

exceed 207 kPa (30 psi). Direct the air flow up the

pleats and down the pleats from the inside of the filter

element. Take extreme care in order to avoid damage

to the pleats.

Do not use air filters with damaged pleats, gaskets,

or seals. Dirt entering the engine will cause damage

to engine components.

The primary air cleaner element can be used up to

six times if the element has been properly cleaned

and inspected. When the primary air cleaner element

is cleaned, check for rips or tears in the filter material.

The primary air cleaner element should be replaced

at least one time per year. This replacement should

be performed regardless of the number of cleanings.

Use clean primary air cleaner elements while dirty

elements are being cleaned.

NOTICE

Do not clean the air cleaner elements by bumping or

tapping. This could damage the seals. Do not use el-

ements with damaged pleats, gaskets or seals. Dam-

aged elements will allow dirt to pass through. Engine

damage could result.

Visually inspect the primary air cleaner elements

before cleaning. Inspect the air cleaner elements for

damage to the seal, the gaskets, and the outer cover.

Discard any damaged air cleaner elements.

There are two common methods that are used to

clean primary air cleaner elements:

• Pressurized air

• Vacuum cleaning

Pressurized Air

Pressurized air can be used to clean primary air

cleaner elements that have not been cleaned more

than two times. Pressurized air will not remove

deposits of carbon and oil. Use filtered, dry air with a

maximum pressure of 207 kPa (30 psi).

82

SEBU8731-04

Maintenance Section

If Equipped

Loading...

Loading...