NOTICE

The low-pressure fuel system can be pressurized for

a time period after the engine has stopped operating.

The operating pressure of the low-pressure fuel sys-

tem can be 500 kPa (73 psi). The secondary fuel fil-

ters should be drained before any maintenance of the

low-pressure fuel system is carried out.

i05294273

Fuel System Primary Filter

(Water Separator) Element -

Replace

Fuel leaked or spilled onto hot surfaces or electri-

cal components can cause a fire. To help prevent

possible injury, turn the start switch off when

changing fuel filters or water separator elements.

Clean up fuel spills immediately.

Note: Refer to Testing and Adjusting Manual ,

“Cleanliness of Fuel System Components” for

detailed information on the standards of

cleanliness that must be observed during ALL

work on the fuel system.

NOTICE

Ensure that the engine is stopped before any servic-

ing or repair is performed.

1. Turn the fuel supply valve (if equipped) to the OFF

position before performing this maintenance.

2. Place a suitable container under the water

separator Clean any spilled fuel. Clean the outside

of the water separator.

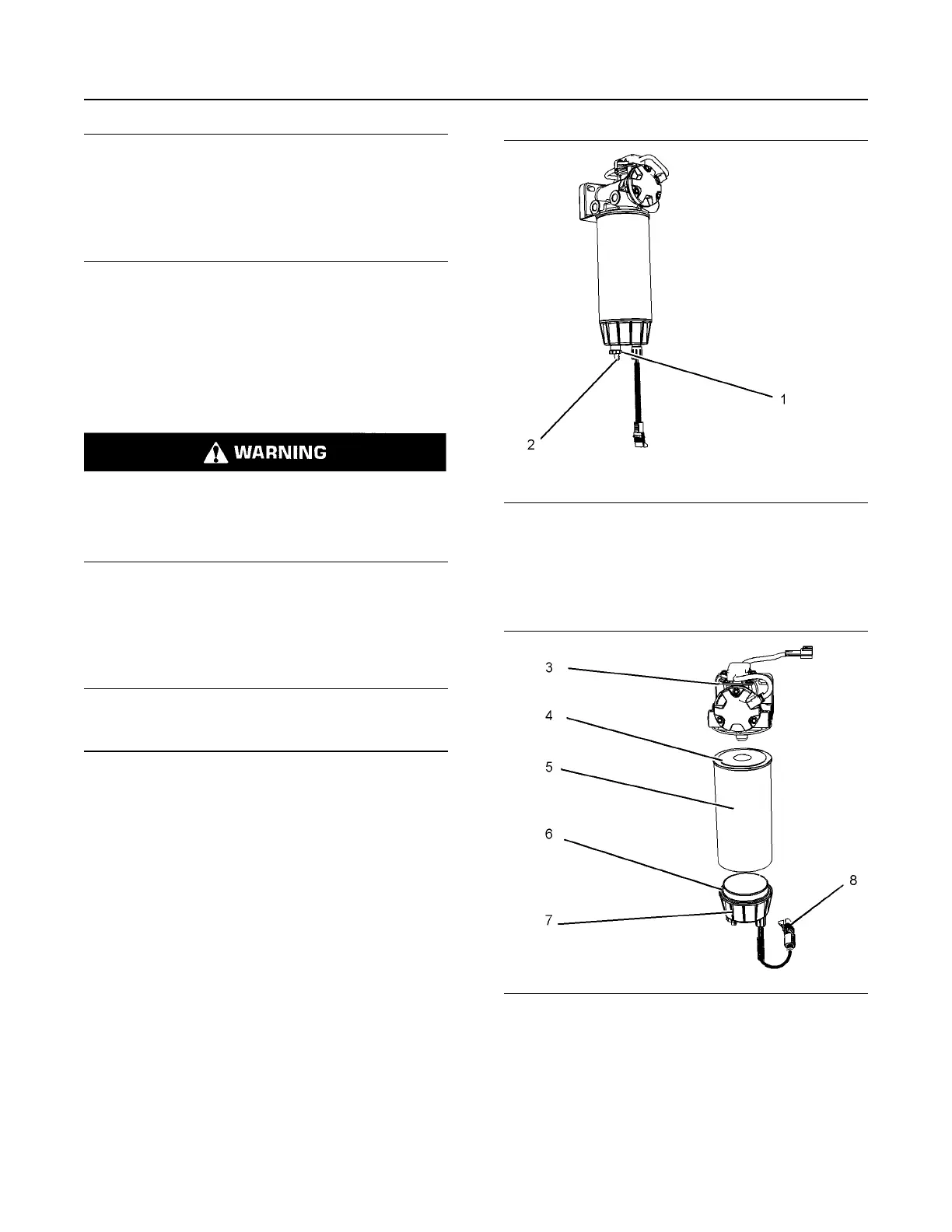

Illustration 58 g03352638

Typical example

3. Install a suitable tube onto connection (2) and

open drain valve (1) and drain the filter. Allow the

fluid to drain into the container. Remove the tube.

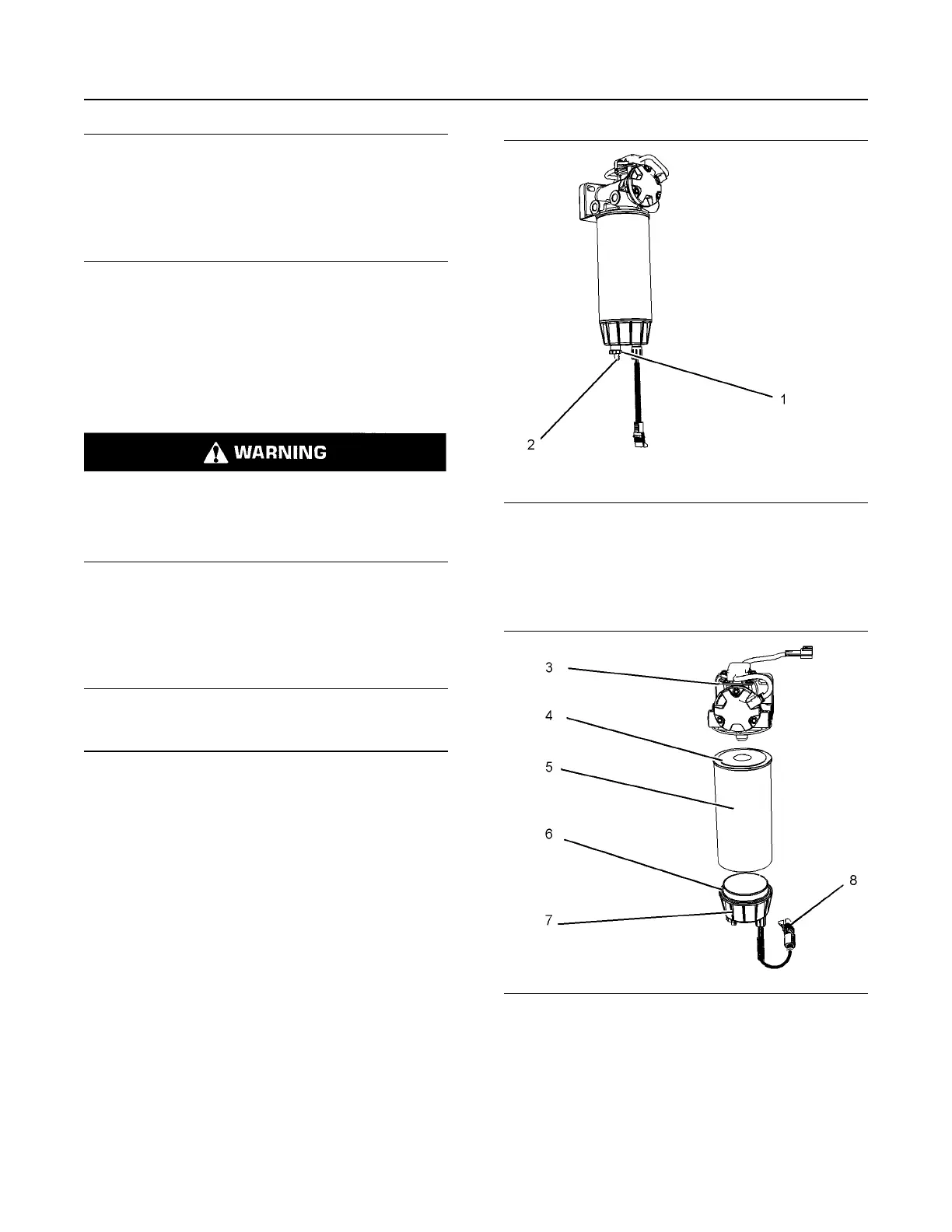

Illustration 59 g03352754

Typical example

4. Disconnect the electrical connector (8) and by

hand remove connecting bowl (7). Remove the old

O ring seal (6). Clean connecting bowl (7).

5. Use a suitable tool in order to remove the fuel filter

(5).

94

SEBU8731-04

Maintenance Section

Fuel System Primary Filter (Water Separator) Element - Replace

Loading...

Loading...