NOTICE

Frequently check the specific gravity of the coolant

for proper freeze protection or for anti-boil protection.

Clean the cooling system for the following reasons:

• Contamination of the cooling system

• Overheating of the engine

• Foaming of the coolant

NOTICE

Never operate an engine without water temperature

regulators in the cooling system. Water temperature

regulators help to maintain the engine coolant at the

proper operating temperature. Cooling system prob-

lems can develop without water temperature

regulators.

Many engine failures are related to the cooling

system. The following problems are related to cooling

system failures: Overheating, leakage of the water

pump and plugged radiators or heat exchangers.

These failures can be avoided with correct cooling

system maintenance. Cooling system maintenance is

as important as maintenance of the fuel system and

the lubrication system. Quality of the coolant is as

important as the quality of the fuel and the lubricating

oil.

Coolant is normally composed of three elements:

Water, additives and glycol.

Water

Water is used in the cooling system to transfer heat.

Distilled water or deionized water is

recommended for use in engine cooling systems.

DO NOT use the following types of water in cooling

systems: Hard water, softened water that has been

conditioned with salt and sea water.

If distilled water or deionized water is not available,

use water with the properties that are listed in Table

12 .

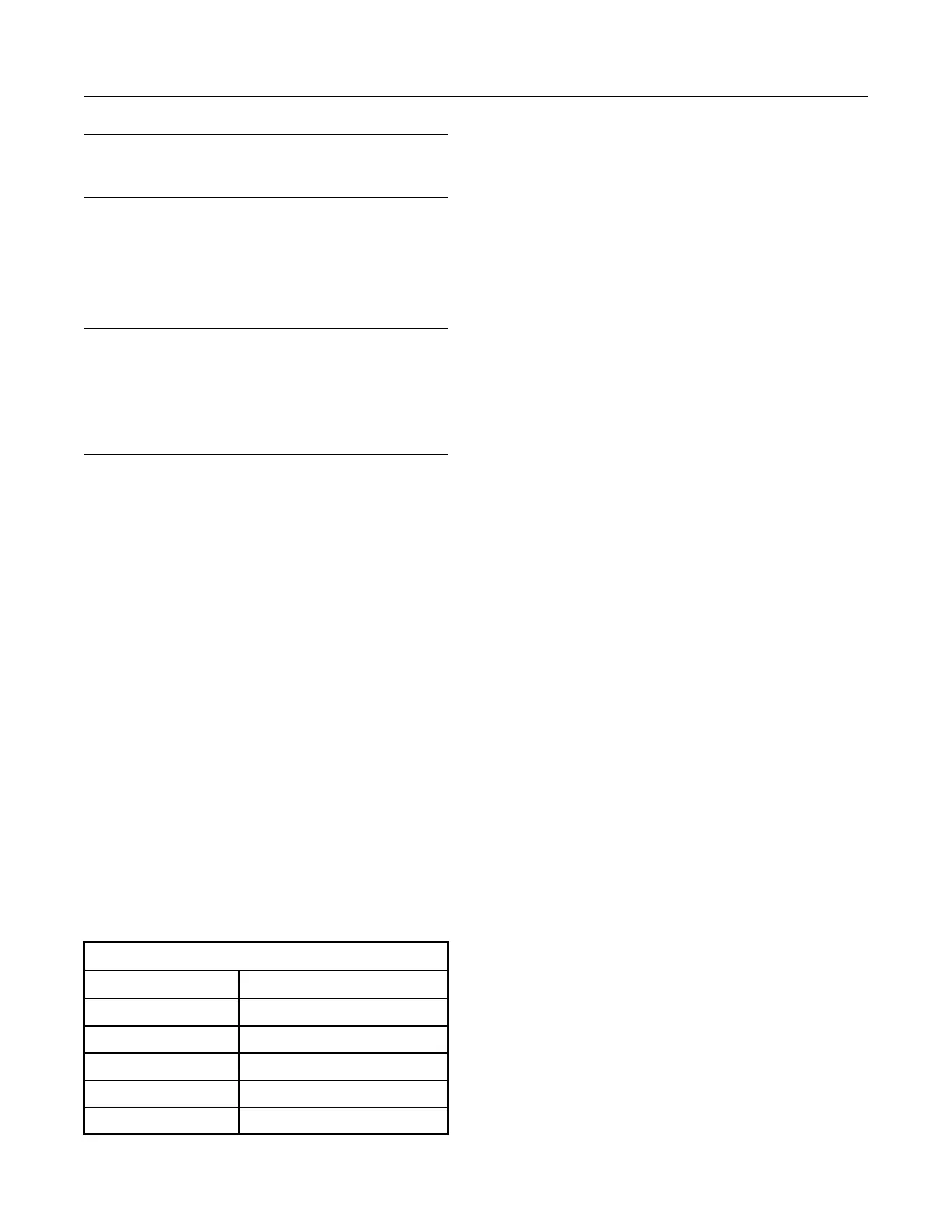

Table 12

Acceptable Water

Property

Maximum Limit

Chloride (Cl) 40 mg/L

Sulfate (SO

4

) 100 mg/L

Total Hardness

170 mg/L

Total Solids

340 mg/L

Acidity pH of 5.5 to 9.0

For a water analysis, consult one of the following

sources:

• Local water utility company

• Agricultural agent

• Independent laboratory

Additives

Additives help to protect the metal surfaces of the

cooling system. A lack of coolant additives or

insufficient amounts of additives enable the following

conditions to occur:

• Corrosion

• Formation of mineral deposits

• Rust

• Scale

• Foaming of the coolant

Many additives are depleted during engine operation.

These additives must be replaced periodically.

Additives must be added at the correct concentration.

Over concentration of additives can cause the

inhibitors to drop out-of-solution. The deposits can

enable the following problems to occur:

• Formation of gel compounds

• Reduction of heat transfer

• Leakage of the water pump seal

• Plugging of radiators, coolers, and small passages

Glycol

Glycol in the coolant helps to provide protection

against the following conditions:

• Boiling

• Freezing

• Cavitation of the water pump

For optimum performance, Perkins recommends a

1:1 mixture of a water/glycol solution.

Note: Use a mixture that will provide protection

against the lowest ambient temperature.

Note: 100 percent pure glycol will freeze at a

temperature of −13 °C (8.6 °F).

68

SEBU9075-03

Maintenance Section

Fluid Recommendations

Loading...

Loading...