4. Install the oil filter (3). Tighten the oil filter by hand.

Do not overtighten the oil filter.

Fill the Engine Crankcase

Refer to the Operation and Maintenance Manual,

Fluid Recommendations for more information on

lubricant specifications. Fill the crankcase with the

correct amount of oil. Refer to the Operation and

Maintenance Manual, Refill Capacities for more

information on capacities.

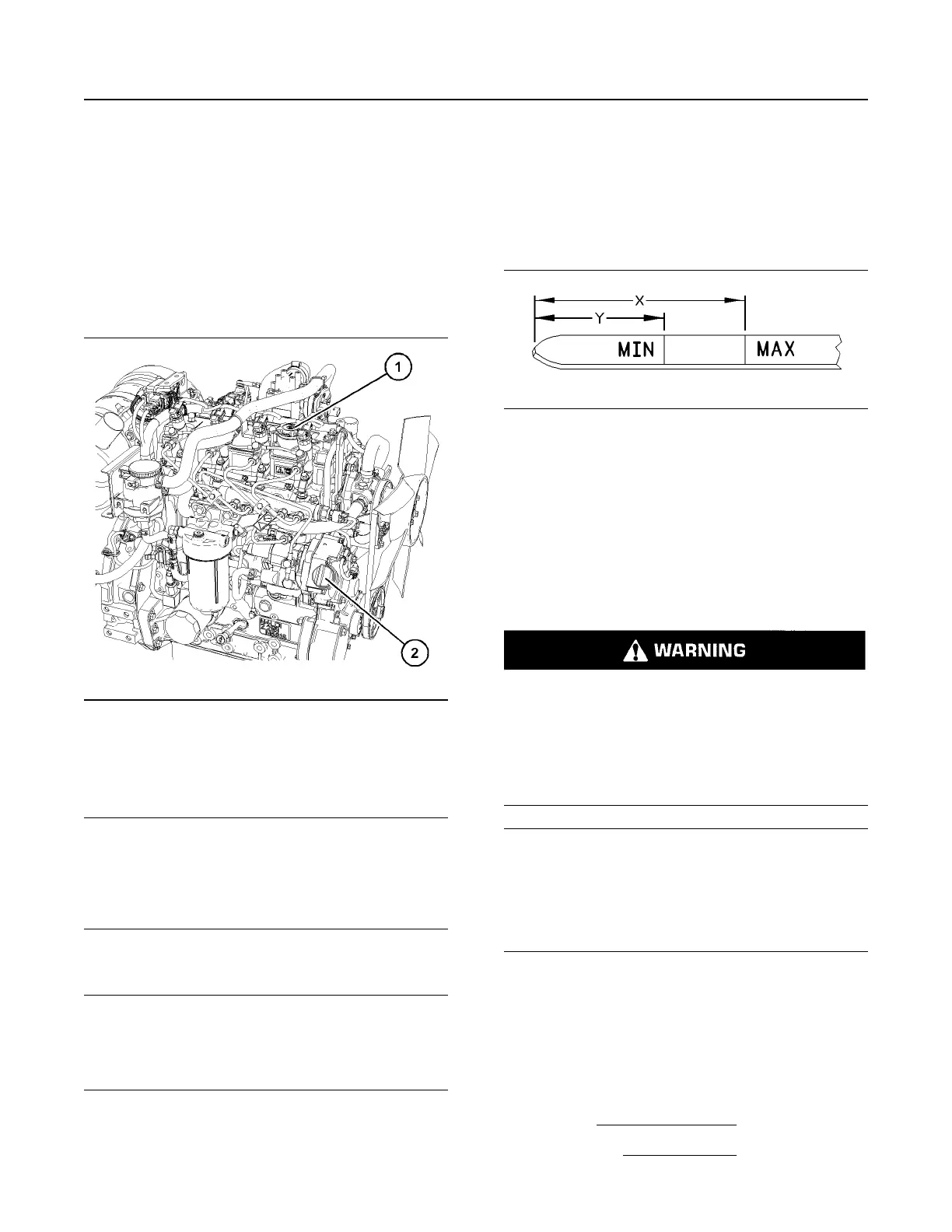

Illustration 73 g06546945

Typical example

(1) Upper oil fill cap

(2) Lower oil filler cap

1. Remove the oil filler cap.

NOTICE

If equipped with an auxiliary oil filter system or a re-

mote oil filter system, follow the OEM or filter manu-

facturer's recommendations. Under filling or

overfilling the crankcase with oil can cause engine

damage.

2. Refill with the correct specification and correct

amount of lubricating oil.

NOTICE

To prevent crankshaft bearing damage, crank the en-

gine with the fuel OFF. This will fill the oil filters before

starting the engine. Do not crank the engine for more

than 30 seconds.

3. Start the engine and run the engine at “LOW IDLE”

for 2 minutes. Perform this procedure to ensure

that the lubrication system has oil and that the oil

filters are filled. Inspect the oil filter for oil leaks.

4. Stop the engine and allow the oil to drain back to

the sump for a minimum of 10 minutes.

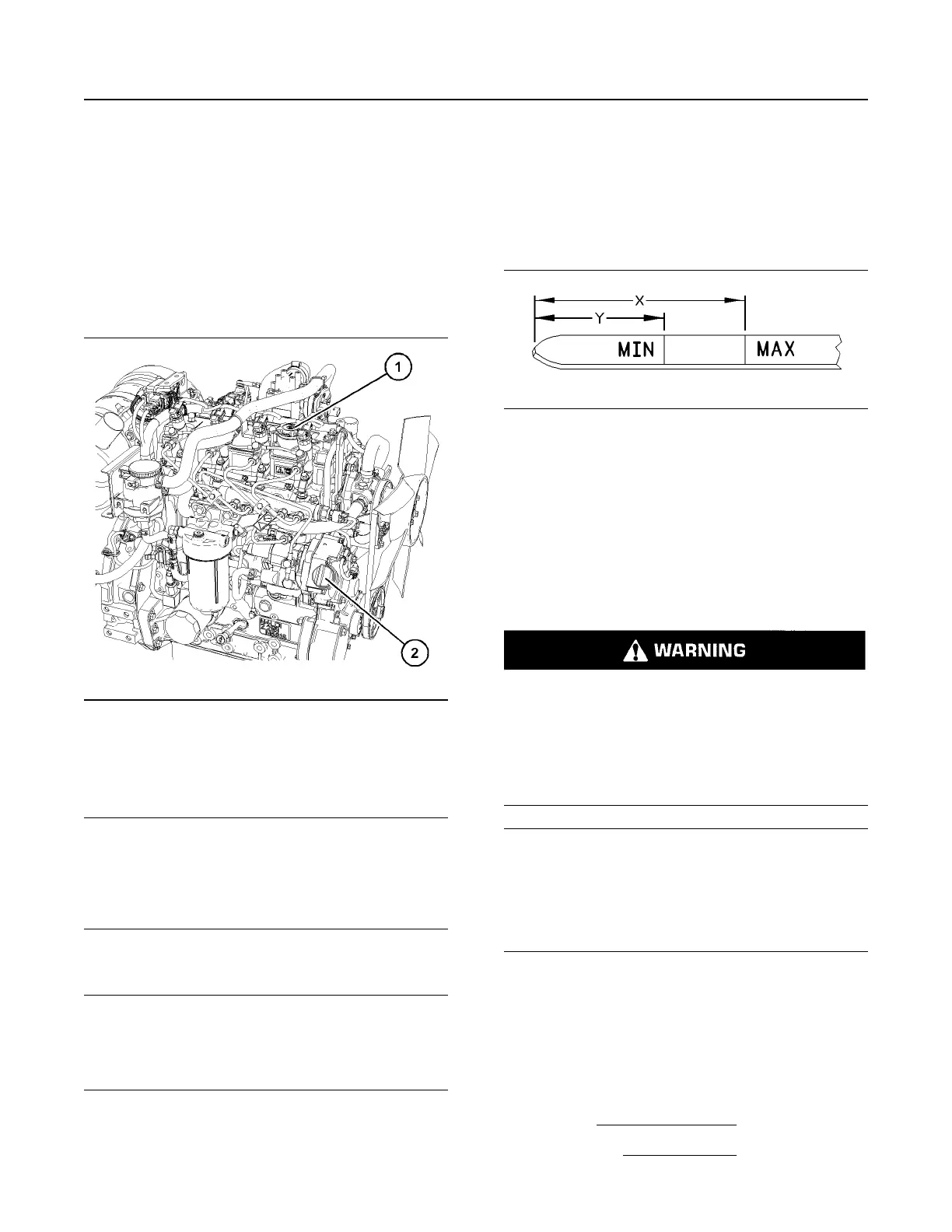

Illustration 74 g00986928

Typical example

5. Remove the engine oil level gauge to check the oil

level. Maintain the oil level between “MIN” and

“MAX” marks on the engine oil level gauge.

i06299296

Engine Valve Lash - Check

Ensure that the engine cannot be started while

this maintenance is being performed. To help pre-

vent possible injury, do not use the starting motor

to turn the flywheel.

Hot engine components can cause burns. Allow

additional time for the engine to cool before

measuring/adjusting valve lash clearance.

NOTICE

Only qualified service personnel should perform this

maintenance.

Operation of the engines with incorrect valve lash

can reduce engine efficiency, and also reduce engine

component life.

This maintenance is recommended as part of a

lubrication and preventive maintenance schedule in

order to help provide maximum engine life. The

maintenance for the valve lash is important in order

to keep the engine compliant.

Ensure that the engine is stopped before measuring

the valve lash. The engine valve lash can be

inspected and adjusted when the engine is cold.

• Inlet valve 0.20 mm (0.8 inch)

• Exhaust valve 0.20 mm (0.8 inch)

M0094137-02 103

Maintenance Section

Engine Valve Lash - Check

Loading...

Loading...