Adjust

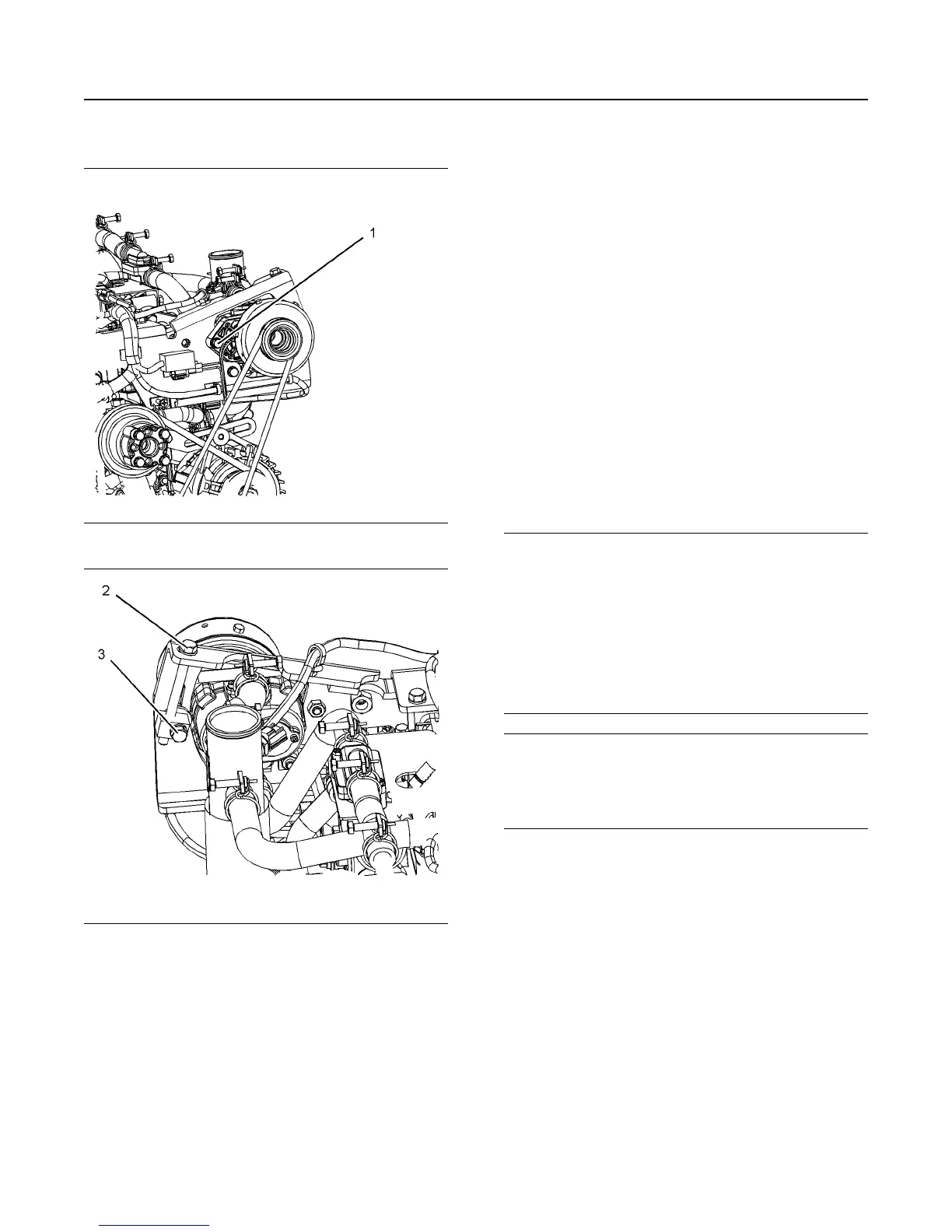

Illustration 45 g03316723

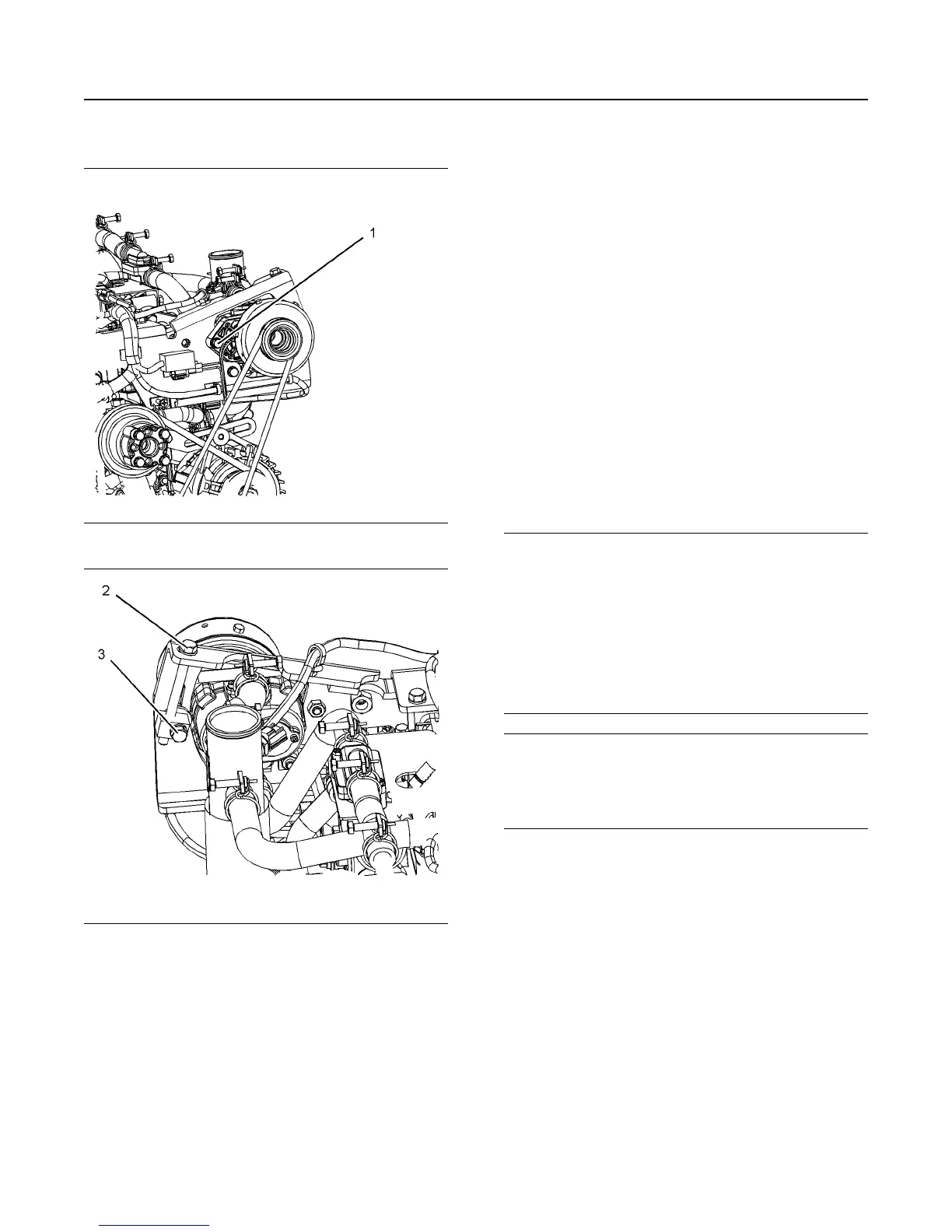

Illustration 46 g03316722

The correct tension for a new belt is 310 N (69 lb).

The correct tension for a used belt that has been in

operation for 30 minutes or more at the rated speed is

220 N (49 lb).

The belt tension should be checked at the center

point of the belt between the pulleys.

1. Loosen bolt (1) and loosen bolt (3).

2. Adjust bolt (2) in order to tension the belt.

3. Tighten bolt (1) and bolt (3) securely.

Replace Belt

The belt should only be replaced if the belt is worn or

damaged.

i05162435

Belts - Inspect/Replace

(Air Pump belt)

The air pump belt must be replaced at 1000 hours.

Refer to Disassembly and Assembly, “Belt (Air Pump)

- Remove and Install” for more information.

i05160093

Coolant (Commercial Heavy-

Duty) - Change

NOTICE

Care must be taken to ensure that fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting and repair of the product. Be

prepared to collect the fluid with suitable containers

before opening any compartment or disassembling

any component containing fluids.

Dispose of all fluids according to Local regulations

and mandates.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Clean the cooling system and flush the cooling

system before the recommended maintenance

interval if the following conditions exist:

• The engine overheats frequently.

• Foaming is observed.

• The oil has entered the cooling system and the

coolant is contaminated.

• The fuel has entered the cooling system and the

coolant is contaminated.

Note: When the cooling system is cleaned, only

clean water is needed.

SEBU8609

77

Maintenance Recommendations

Belts - Inspect/Replace

Loading...

Loading...