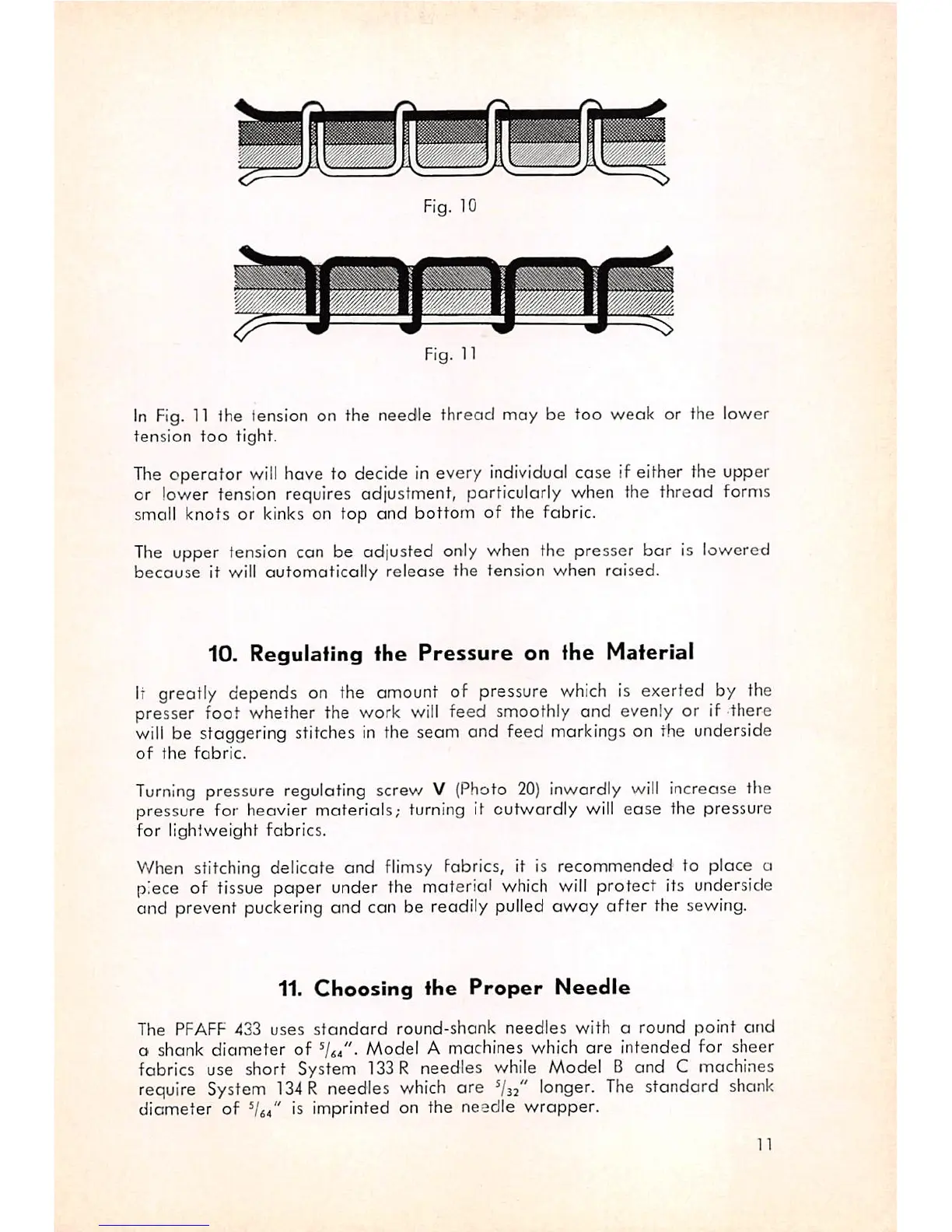

Fig. 10

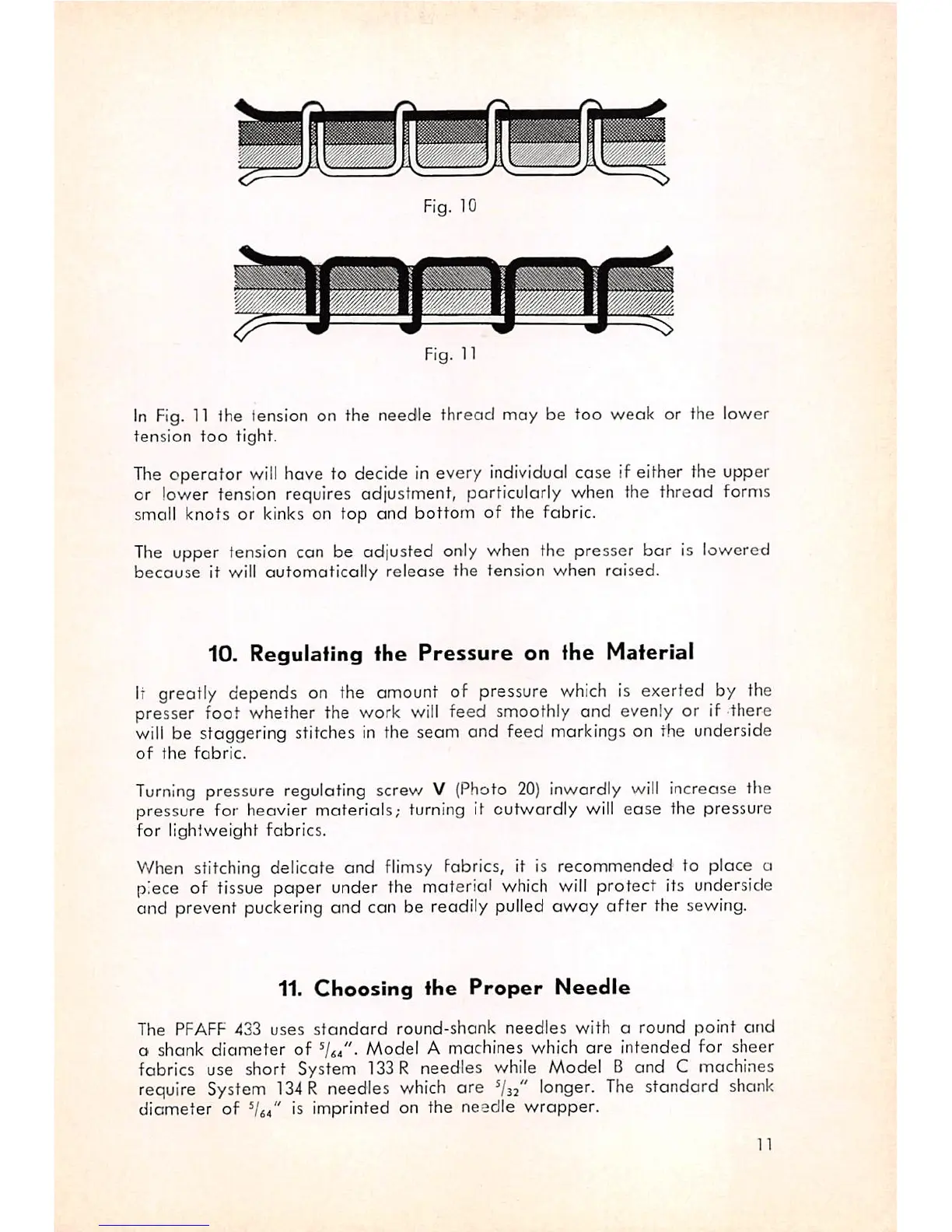

Fig. 11

In

Fig.

11

Ihe

tension

on the needle thread may be too weak or the lower

tension

too

tight.

The operator

will

have to decide in every individual case if either the upper

or lower tension requires adjustment, porticularly when the thread fornts

small knots or kinks on top

and

bottom

of the fabric.

The upper tension can be adjusted only when the presser

bar

is lowered

because

it will

automatically

release

the tension

when

raised.

10. Regulating

the

Pressure

on the Material

it greatly depends on the amount of pressure

which

is exerted by the

presser foot whether the work

will

feed smoothly and evenly or if there

will

be staggering stitches in the seam and feed markings on ihe underside

of

the

fabric.

Turning

pressure regulating screw V

(Photo

20)

inwardly

will

increase tlie

pressure for heavier materials;

turning

it outwardly

will

ease the pressure

for lightweight fabrics.

When stitching delicate and

flimsy

fabrics, it is recommended to place a

piece of tissue paper under the material

which

will

protect its underside

and prevent puckering and can be readily pulled

away

after

the sewing.

11.

Choosing

the

Proper

Needle

The PFAFF 433

uses

standard

round-shank

needles

with

a

round

point

atid

o

shank

diameter

of

Model

A

machines

which

are

intended

for

sheer

fabrics use short System 133 R needles while Model B and C machines

require

System

134

R needles

which

are

longer.

The

standard

shank

diameter

of is imprinted on the needle

wrapper.

11

Loading...

Loading...