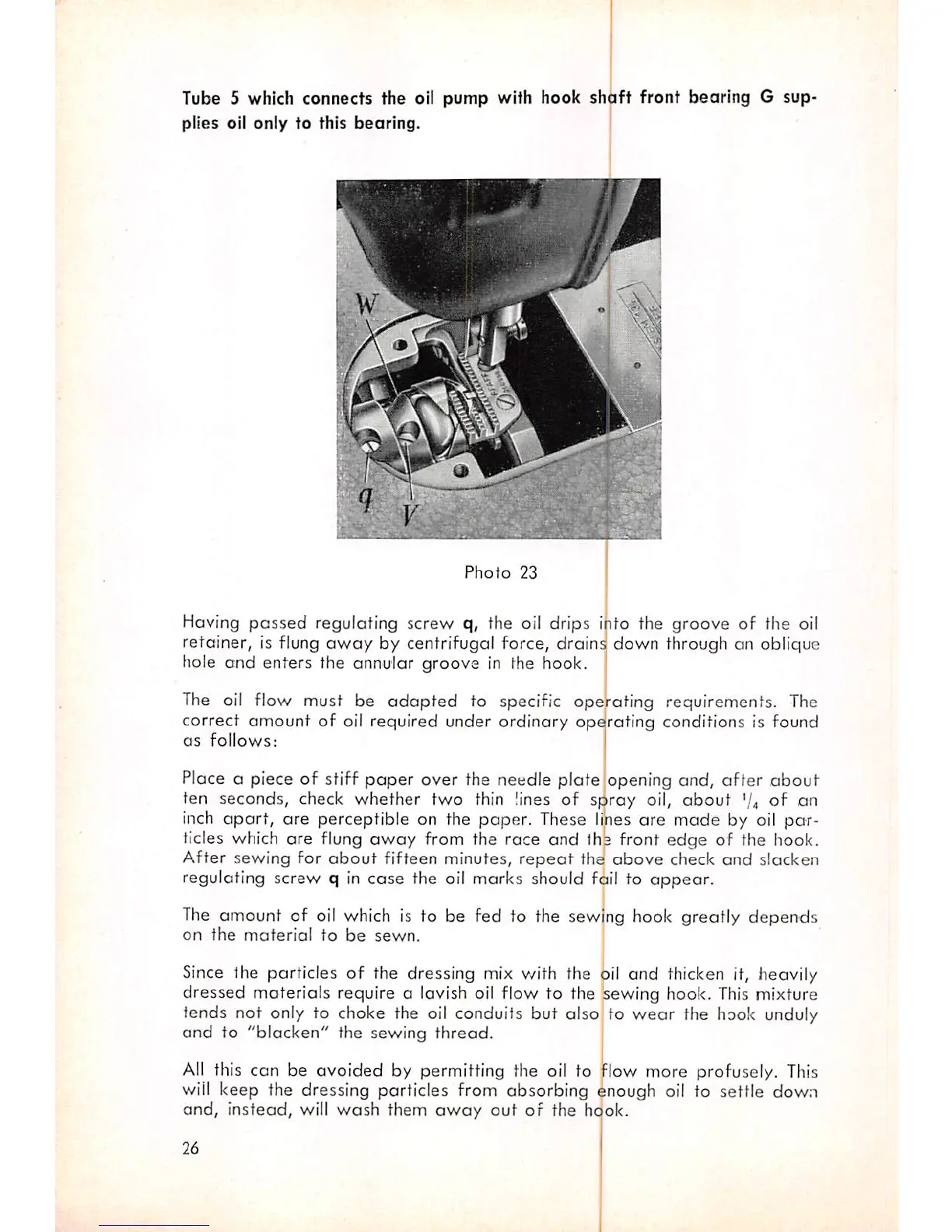

Photo

23

Tube 5

which

connects the oil pump with hook shdft front bearing G

sup>

plies

oil

only

to

this

bearing.

Having

passed

regulating screw q, the oil drips

retainer,

is flung

away

by centrifugal

force,

drains

hole

and

enters the annular groove in the hook.

i

ito

the

groove

of

the

oil

down

through

an

oblique

The oil flow must be

adapted

to specific operating requirements. The

correct

amount

of

oil

as

follows:

required

under

ordinary

ope

rating

conditions

is

found

Place

a

piece

of stiff paper over the

needle

plate

jopening

and, after about

ten

seconds,

check

whether

two

thin

lines

of

Sfiray

oil,

about of on

inch

apart,

are perceptible on the paper. These lines are

made

by oil

par

ticles which

are

flung

away

from the roce and Ihe front

edge

of the hook.

After

sewing

for

about

fifteen minutes,

repeat

the

above

check

and

slacken

regulating screw q in case the oil marks should foil to appear.

The amount of oil which is to be fed to the sewing hook greatly depervds

on

the

material

to

be

sewn.

Since

the

particles

of

the

dressing

mix

with

the

i)il

and

thicken

it,

heavily

dressed materials require a lavish oil flow to the

dewing

hook.

This

mixture

tends not only to choke the oil conduits but also to

wear

the hook unduly

and

to

"blacken"

the

sewing

thread.

|

All this con be avoided by permitting the oil to flow more profusely. This

will

keep

the dressing particles from absorbing enough oil to settle down

and,

instead,

will

wash

them

away

out

of

the

hook.

26

Loading...

Loading...