GB 02999 - Edition 07 - 01/2017

1/3

B 330

Nitrogen purge and air inlet valve

device connections

Nitrogen

characteristics

Depending on the application, the inert gas purge can consist of:

– injecting ambient air, or

– injecting an inert gas into the pump.

In this manual, the inert gas will be called ‘nitrogen’, as it is the most

commonly used gas.

For more information about the type of purge gas, contact your service

centre Pfeiffer Vacuum.

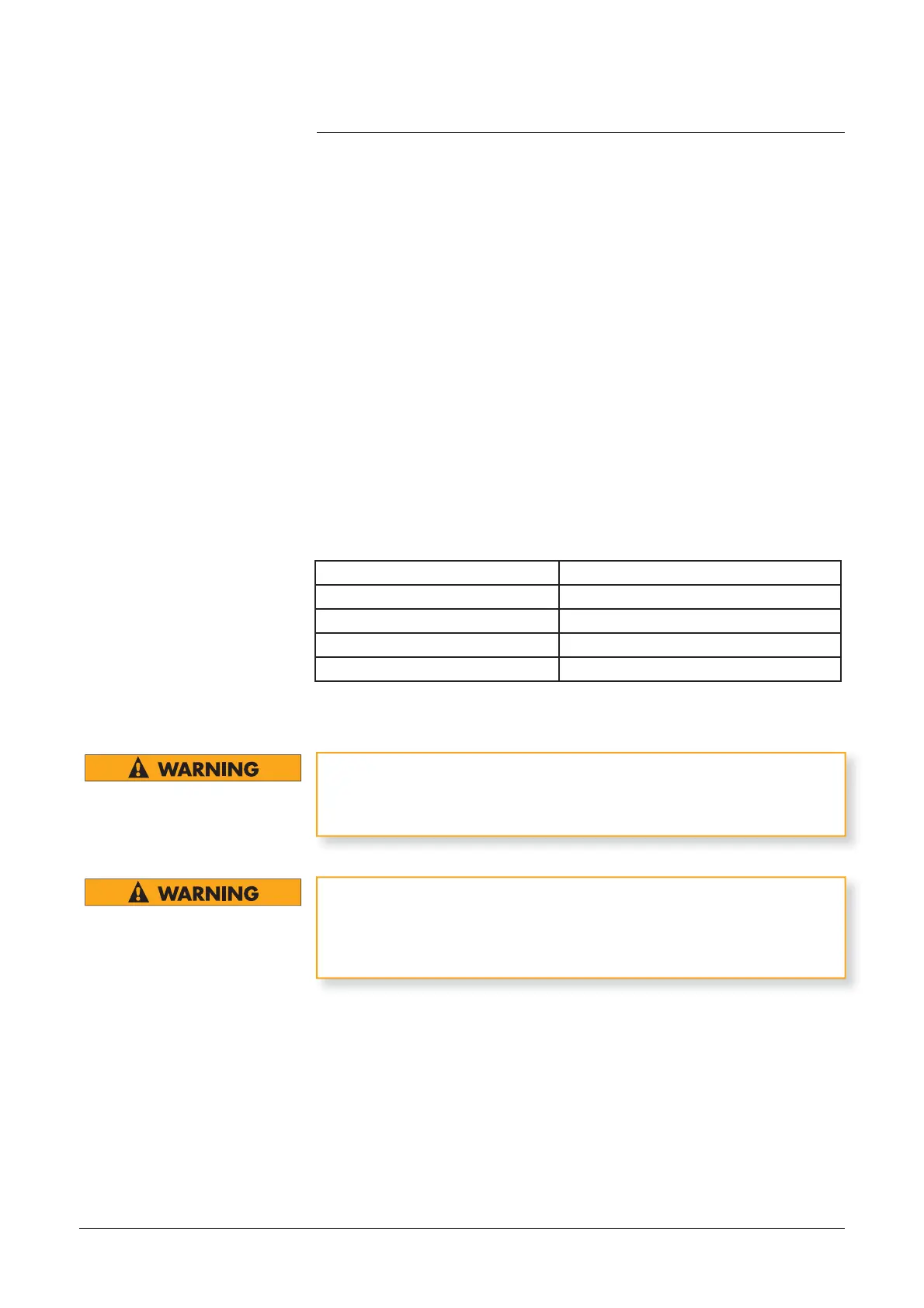

H

2

O concentration < 10 ppm v

O

2

Concentration < 5 ppm v

Dust < 1 μm

Oil < 0.1 ppm v

Pression absolue 1 ·10

3

to 1.2 ·10

3

hPa

A filtered dry nitrogen supply with the characteristics defined is required

for optimum performance, see below.

When the inert gas purge is stopped, the pumped gases can pass

from rough vacuum side to high vacuum side and damage the

maglev bearings.

It is advised to maintain the purge flow as long as the rotor is

running to protect pump internal parts.

Pressurised circuit

To work safely on the product, the operator must:

Install a manual valve on the nitrogen circuit at a distance of 3 m from

the product, so that the nitrogen supply can be locked.

Pfeiffer Vacuum SAS – Operating instructions - ATH 1603 M - 2303 M

Loading...

Loading...