OperatingInstructions&PartsManual

HorizontalRotaryTables

DividingPlates

Pg. 8

TroubleshootingChart

Symptom PossibleCause(s) CorrectiveAction

Handwheelrotates:

Tabledoesnotrotate

1.Key(Ref.No.32)ismissing

1.InsertKey

2.WormShaftdisengaged 2.Engagewormshaft

(seeoperation)

Handwheelwillnotrotate 1. Hold‐downclampsare

tootight

2.Locknuttootight

(seemaintenance)

3.Tableneedlubrication

1. Loosenhold‐downclamps

2. Adjustlocknutproperly

3. Lubricateproperly

(seeMaintenance)

WormShaftwillnotengage

Table

Eccentricsleevecannotrotate

properly

Properlyadjustthreadedpinand

Setscrew(seemaintenance)

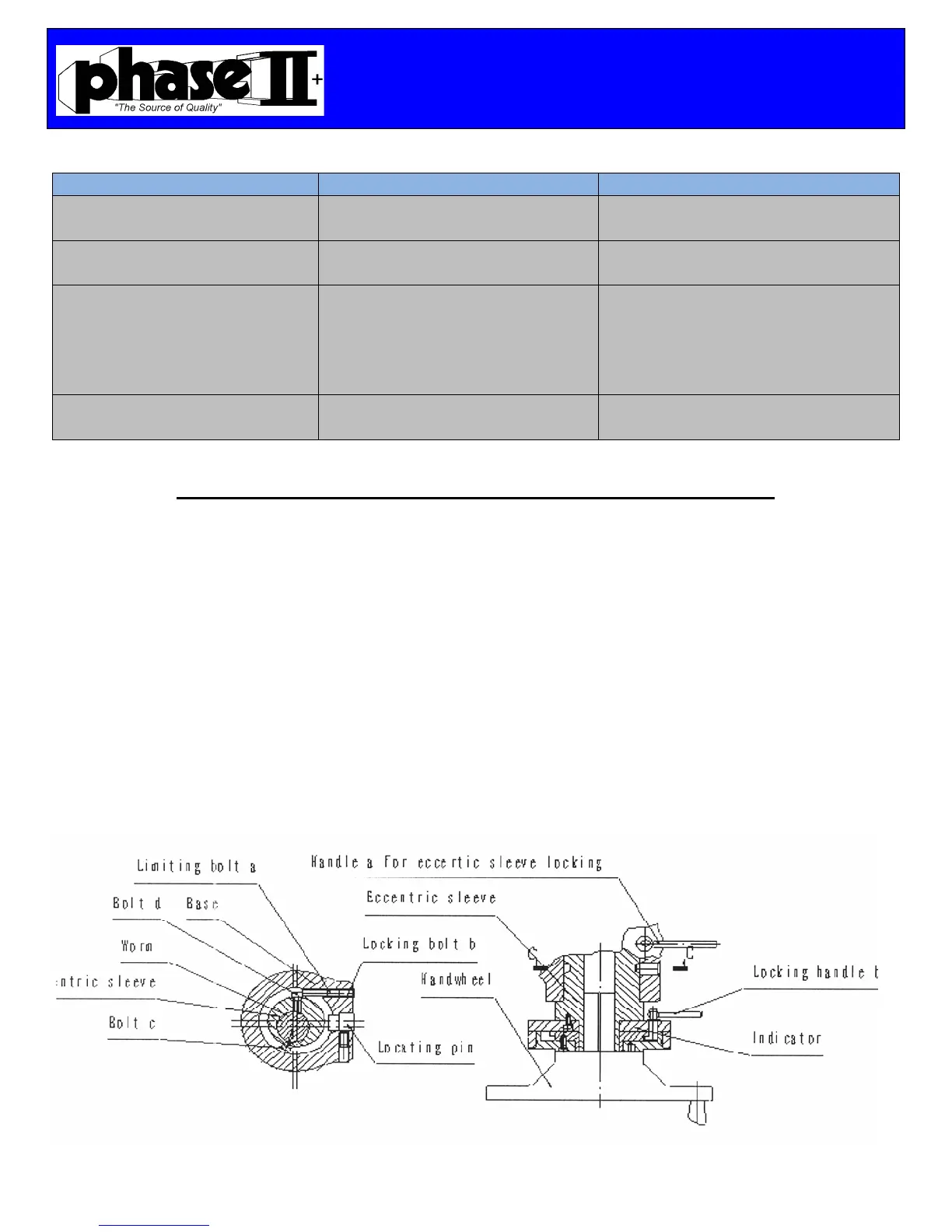

WormGear/EccentricSleeveAdjustment

First Loosen Handle A for the eccentric sleeve lock and proceed to unscrew Bolt B.

Screw clockwise the Limiting Bolt A to adjust the mesh of the worm gear to the table top gear.

At this time, rotate the handle wheel clockwise and counterclockwise to ensure the mesh of the

worm gear is within 6° and then tighten the Locking Bolt B and then clamp the Handle A to

lock the eccentric sleeve.

Screw counterclockwise the Limiting Bolt A to reduce the mesh and proceed to rotate the

handwheel to ensure the mesh of the worm gear is within 6° and then tighten Locking Bolt B.

Rotate the Indicator counterclockwise until the Bolt C is touching the Locating Pin. This

procedure has just disengaged the worm gear. Rotate the indicator clockwise until Bolt D is

touching Bolt A. Now the worm gear is engaged.

Loading...

Loading...