Reference: WX-B-009-01

Title: Product Performance

Specification

Rev./Status: 0.2 / Draft

Model : FX20 FX30 FX50 Page 8 of 19

-

FX20 FX30 FX50

Mini Audio system

- 2013-12-09

2 - 2014-02-28

3

NAME

Suhaofeng/Tangbing 19 10 - 8 A4

CHECK DATE

2014-02-28

For /61 (Korea) K 60065 6

th

Edition

For /96 (Taiwan) CNS 14408 (IEC 60065 7

th

Edition)

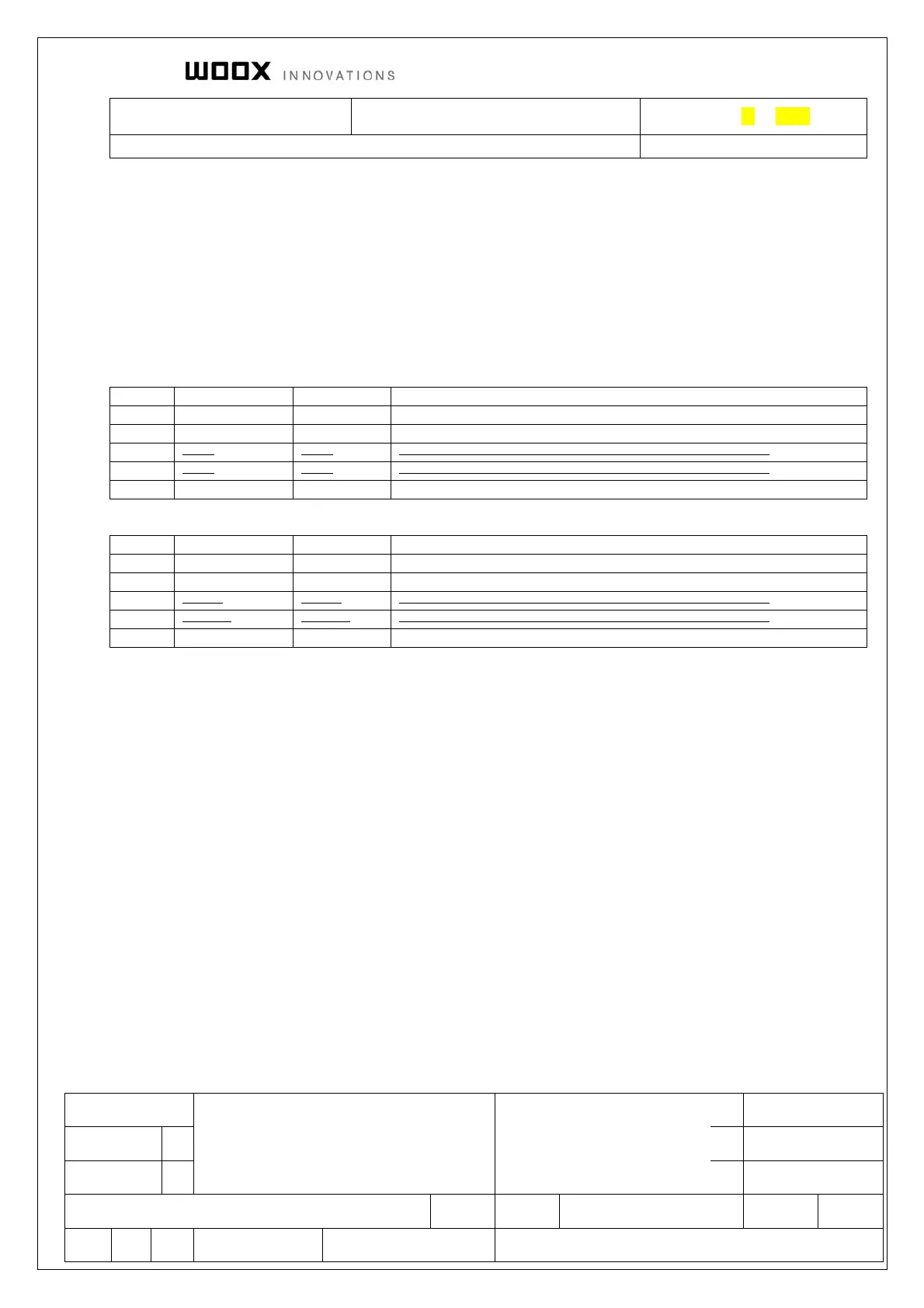

2.5 ESD Requirements

The product shall withstand electro static discharges on all user accessible parts of the product.

Reference: IEC61000-4-2.

For contact discharges:

Level General (kV) USA (kV) Requirement

1 0-2 0-3 No deviations allowed.

2 >2-4 >3-4 Short perceptible deviations allowed.

3 >4-5 >4-5 Normal recallable functions function changes allowed.

4 >5-7 >5-7 Control recallable functions function changes allowed.

5 8 8 Components damage not allowed.

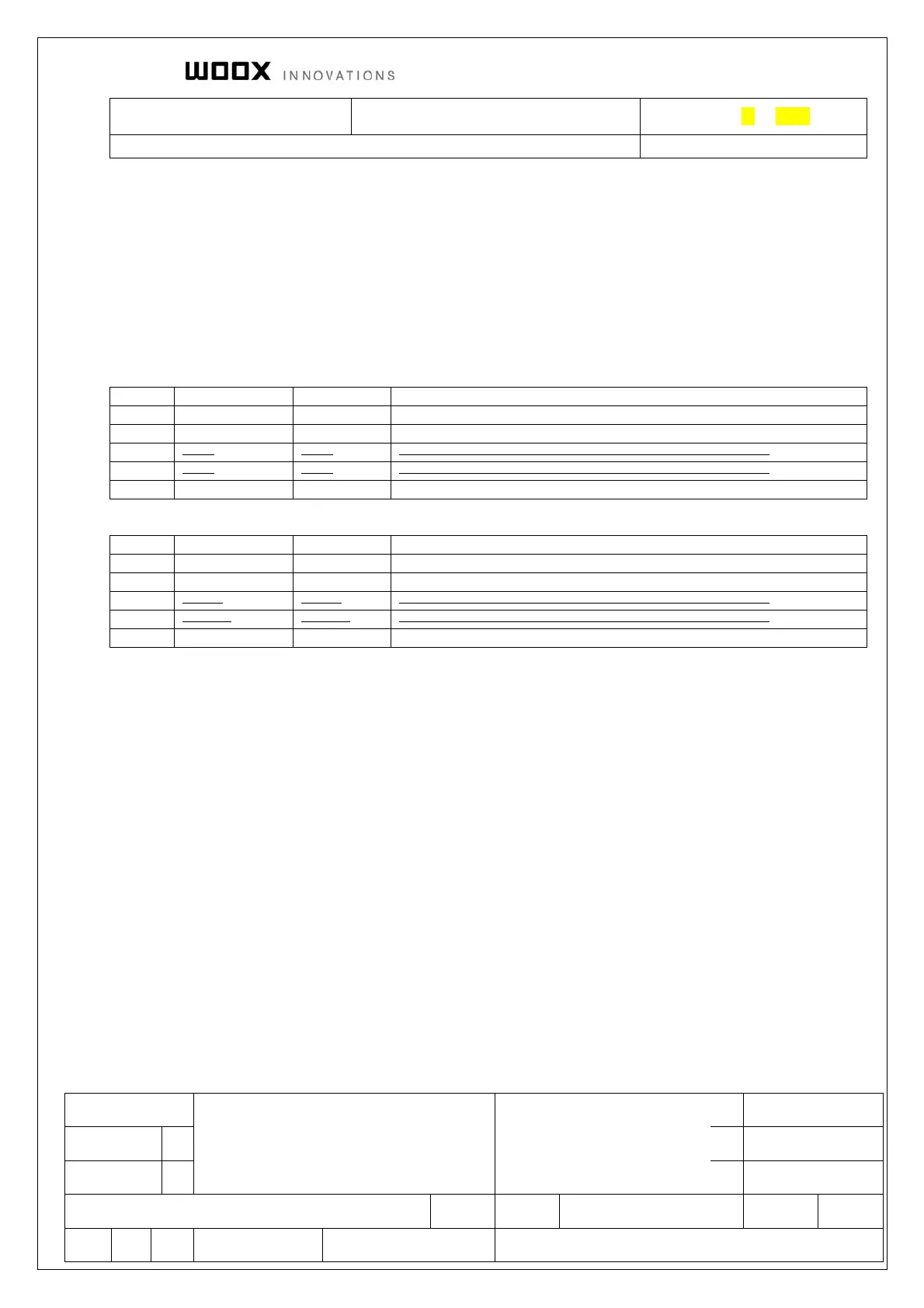

For air discharge:

Level General (kV) USA (kV) Requirement

1 0-4 0-6 No deviations allowed.

2 >4-8 >6-8 Short perceptible deviations allowed.

3 >8-10 >8-10 Normal recallable functions function changes allowed.

4 >10-15 >10-15 Control recallable functions function changes allowed.

5 15-18 >15-18 Components damage not allowed.

General requirement:

1. 10 arcs for positive and negative polarity for unit “on” and “off” for 1kV incremental steps.

2. Component or mechanical damage is not allowed. No loss of fixed stored data (stored in EEPROMs).

3. Hang-ups and malfunctions are allowed, as long as the customer can “recover” from the hang-up by

pressing theStandby or ON/OFF button of the set.

4. Failures that disappear only by unplugging the AC mains cord and/orpower sources are not acceptable.

2.6 Environmental Condition

The environmental condition requirements and test method is according to UAN-D1590.

Ambient temperature : max. 40 ° C - all climates

Apparatus acc. to spec. : +5 to + 35 ° C

Vibration test (acc. IEC 60 068/2/6) : operational vibration test to be proceeded in operating position of the

set.

2.7 Quality

PQR-class: class Ⅲ according toBLC A&MA PQR handbook V2.1 (2006-10-02)

2-5

Loading...

Loading...