5

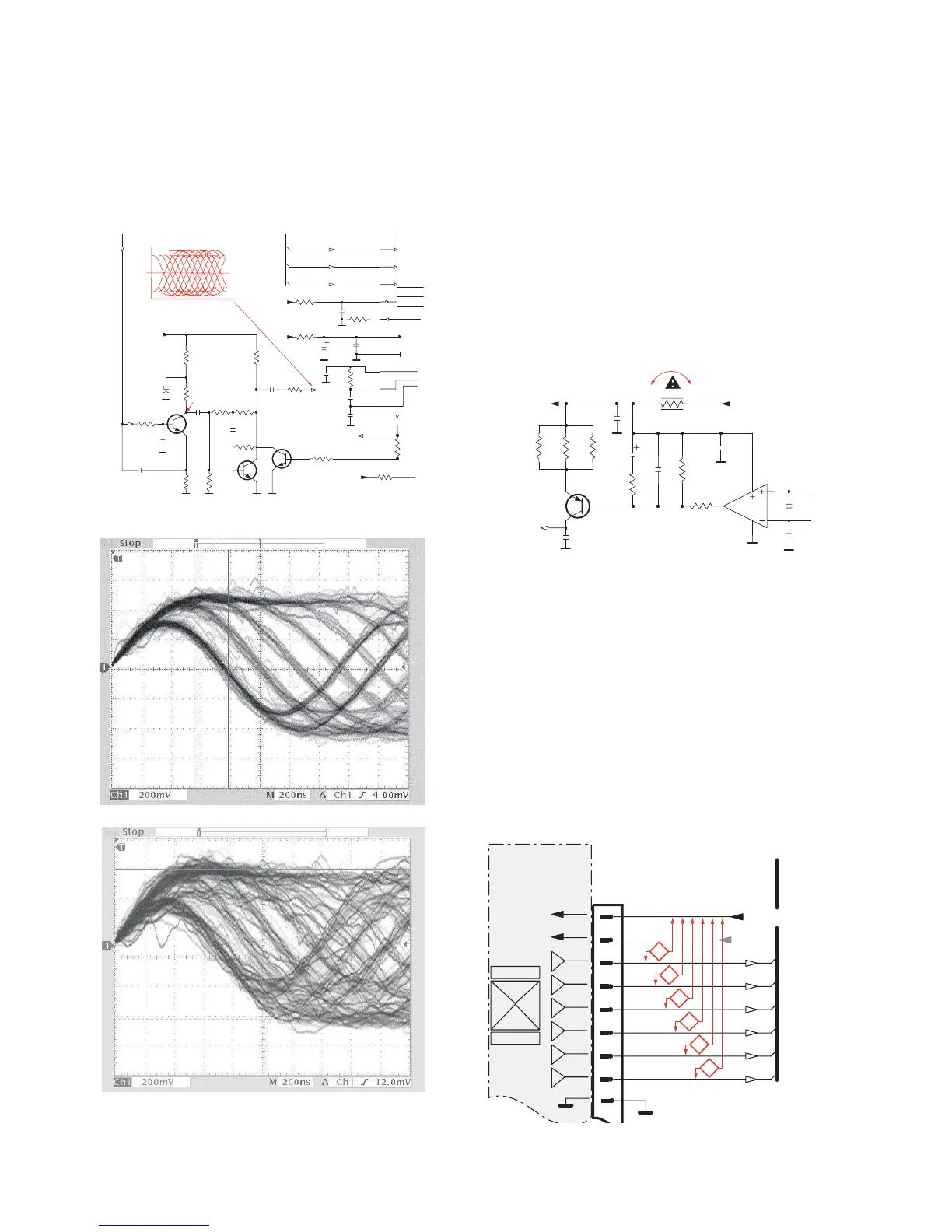

EYE-PATTERN SIGNAL – JITTER MEASUREMENT

Measure the signal on the input of the Signal processor

using an analog oscilloscope. Please find the exact

measuring point in your Service Manual.

See below examples of the signal. Amplitude should read at

least 700mVpp using SBC444A.

good

bad

If the oscilloscope shows a signal like the ‘bad’ one, and/or

the amplitude decreases within 1 minute - the CD drive has

to be replaced.

6

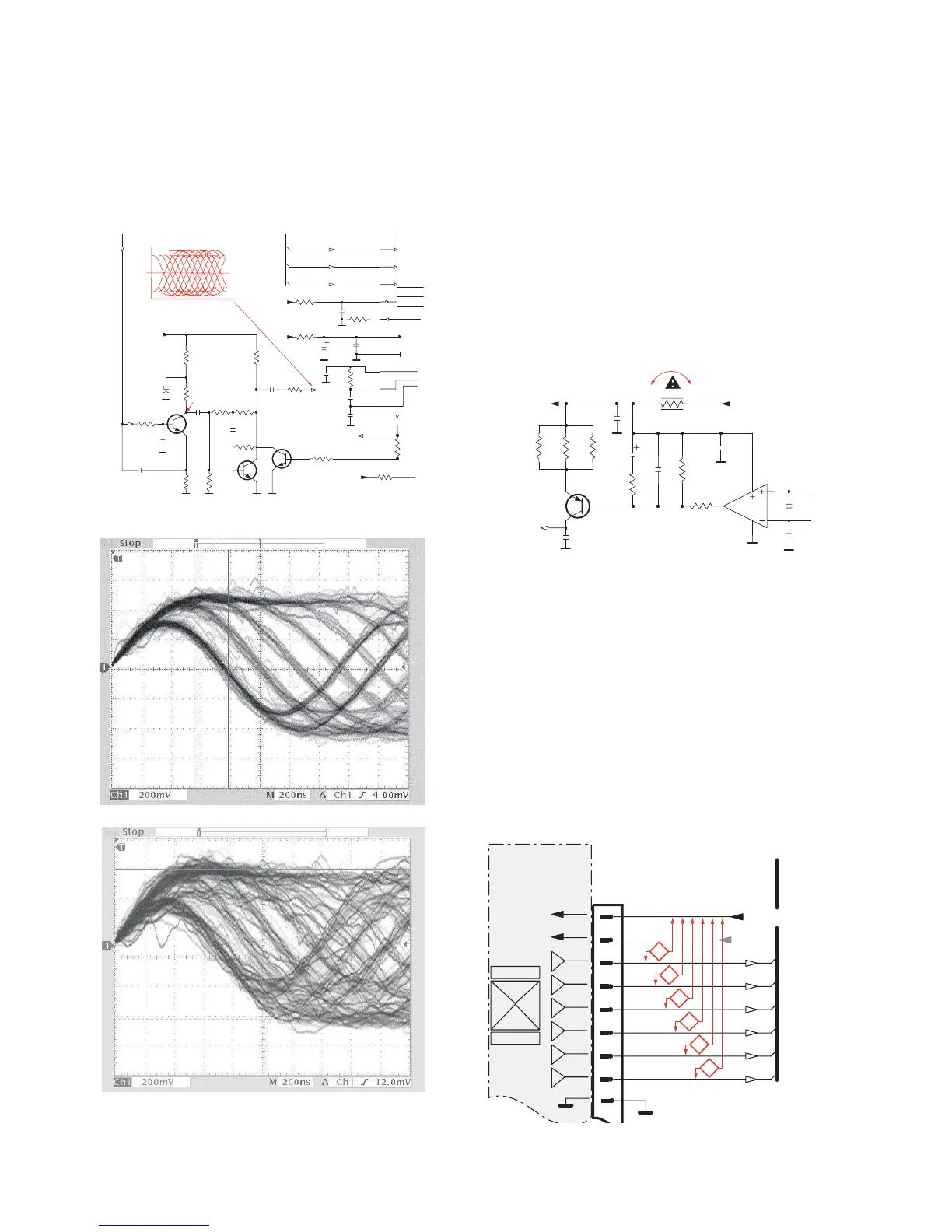

CD DRIVE – LASER CURRENT MEASUREMENT

The laser current can be measured as a voltage drop on a

resistor. The resistor is marked in every Service Manual.

The value depends on the type of CD drive.

typical value most probably defect

VAMxxxx : 150-230mV t350mV

MCDxx : 170-230mV t300mV

DA1x : 210-250mV t350mV

DA2x : 175-200mV t250mV

Use SBC444A (CD-DA) for measurement.

7

CD DRIVE – OFFSET MEASUREMENT

The photodiodes of the CD-drive may have an offset. These

offsets have to be compensated by the signal processor.

High offsets can lead to poor playability of some CDs

(skipping tracks).

To measure the offset values, start the Service Test

Program - section “Focus Test” without a CD.

The offsets can be measured with a DC Millivoltmeter

directly on the connector (see drawing below). Pin

numbering varies from drive to drive.

The values from diode A-D should read 0±10mV.

Diodes E and F are less critical.

If one of the offsets is higher than ±10mV the CD drive has

to be replaced. Otherwise replace the Signal Processor.

Sanyo DA12T3

CD Drive

A

A

F

C

B

E

C

D

E

VCC

B

VREF

F

D

9

10

11

12

13

14

15

16

1800

+5V_HF

VrefCD10

A

D

E

B

C

F

GND

8

E

D

A

B

C

F

Laser power control

100n

2878

470n

2876

3821

1R

1K

3823

2880

33p

+5V

BC807-40

7879

3817

47R

3820

4R7

47R

3819

1n

2879

2877

47u

1

8

4

7811-A

LM358D

3

2

10K

3822

47R

3818

2841

100n

47n

2869

+5V_HF

LASER DIODE

U >250mV

->Laser damaged !

4,6V

3V

3,3V

3,9V

2V

0,17V

0,17V

Sanyo

DA12T3

HF-Amplifier

D3

D2

D1

Loading...

Loading...