XSMALL 06 SERVICING AND MAINTENANCE

01/02

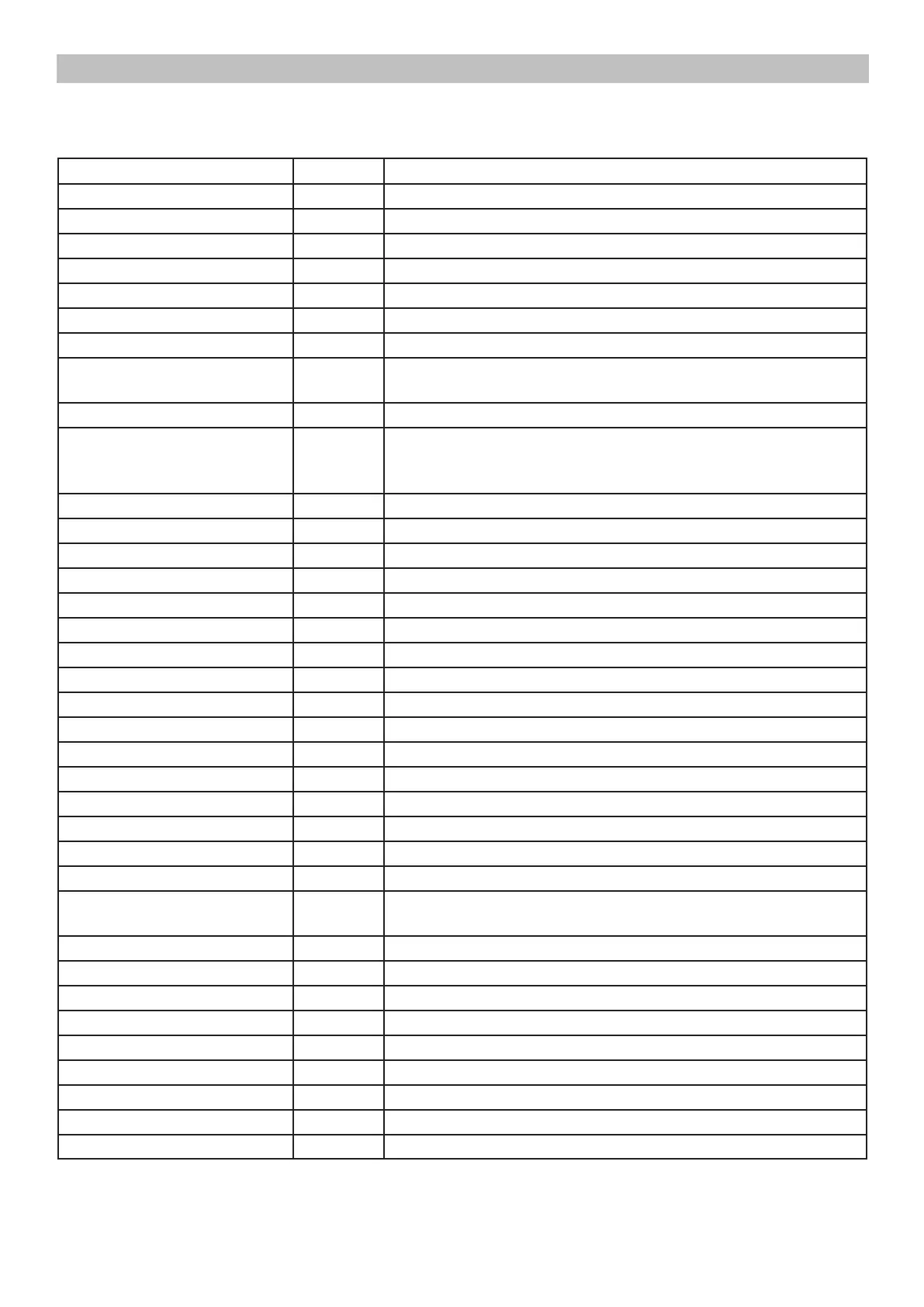

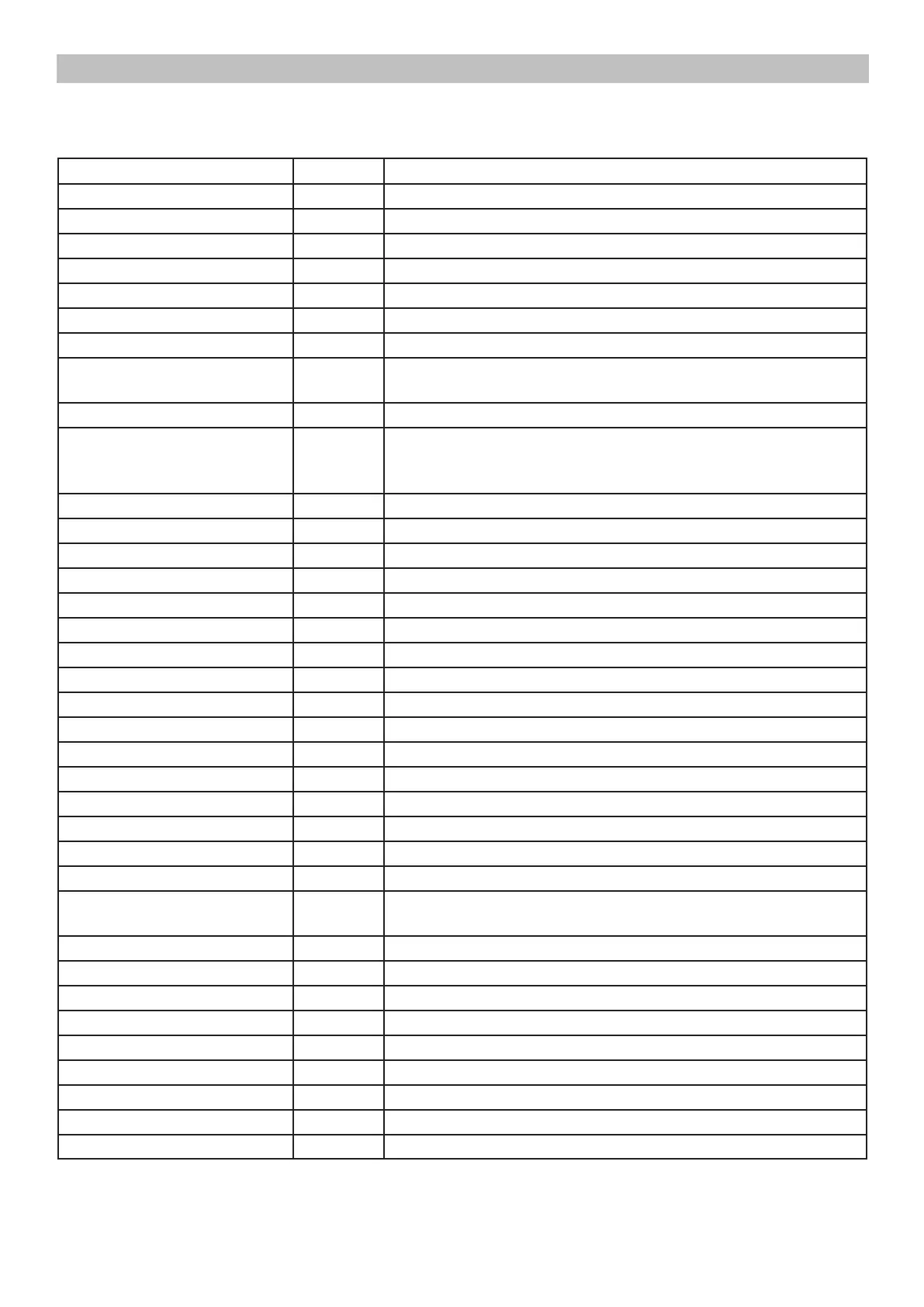

6.1. Repair Flow

Proces stap Saeco no. Action

Intake 1 Visual inspection (transport damage) take care for pictures

2 Check Type/serialnumber

Log all available accessory

Diagnosis 3 Check product for consumer complaint (NFF contact consumer)

4 Opening machine

5 Visual inspection check for loosen parts, leaking etc..

6 Operational tests

Repair Run Diagnostic to get error codes and relevant set statistics (Saeco

Service Center SSC)

7 Repairing the faults encountered

8 "Checking any modications (view Symptom Cure, new soware,

etc.)

Refer Annex tabs per family"

9 Service activities in accordance with the operating schedule

Check/Replace Waterlter (the small lter, not the Britta lter)

Check/Replace Water tank lip seal

Check/Replace Boiler pin O-ring

Clean/align Coee grinder (Vacuum cleaner / brush)

Descale the water Circuit

Check/Replace Hot water/steam valve

10 Internal check / cleaning

Check/Clean/Grease Brewing unit

11 Operational test while the appliance is open

Check Hoses, attachments and Oetiker clamps

Check Pump for operation & noise

Check Gear motor for operation & noise

Check for leakage

12 Assembly

13 Final inspection test

14 Steam out before shipping out, if temperature is below 0° to prevent

any demaged due to frozen water

Inspection

visual Do cabinet parts t well together

Check for damages

Power check Will the set switch on

Accesoires Do the accessories match with the intake

Consumer complaint Check the product for the consumer complaint

Coee

Dispense Make 2 * coee. Are both amounts equal

Make e 2 cups at the same time. Are the volumes equal

Loading...

Loading...