2)、Look over and clear the failure according to below information.

Failure

Possible causes for the failure

Solutions

Heat pump

cannot

be started

1 Wrong power supply

2 power supply cable loose

3 circuit breaker open

1 shut off the power and check power supply;

2 check power cable and make right connection

3 check for the cause and replace the fuse or

circuit breaker

Water pump is

running with

high noise or

without water

1 lack of water in the piping

2 much air in the water loop

3 water vavles closed

4 dirt and block on the water filter

1 check the water supply and charge water

to the piping;

2 discharge the air in the water loop;

3 open the valves in water loop;

4 clean the water filter.

Heat pump

capacity is low,

compressor

do not stop

1 lack of refrigerant;

2 bad insulation on water pipe;

3 low heat exchange rate on air side

exchanger;

4 lack of water flow

1 check for the gas leakage and recharge the

refrigerant;

2 make good insulation on water pipe;

3 clean the air side heat exchanger;

4 clean the water filter

High compressor

exhaust

1 too much refrigerant

2 low heat exchange rate on air side

exchanger

1 discharge the redundant gas

2 clean the air side heat exchanger

Low pressure

problem

of the system

1 lack of gas

2 block on filter or capillary

3 lack of water flow

1 check the gas leakage and recharge freon;

2 replace filter or capillary;

3 clean the water filter and discharge the air in

water loop.

Compressor do

not run

1 power supply failure

2 compressor contactor broken

3 power cable loose

4 protection on compressor

5 wrong setting on return water temp.

6 lack of water flow

1 check off the power supply;

2 replace compressor contactor;

3 tighten the power cable;

4 check the compressor exhaust temp.;

5 reset the return water temp.;

6 clean the water filter and discharge the air in

water loop.

High noise of

compressor

1 liquid refrigerant goes into compressor

2 compressor failure

1 bad evaporation, check the cause for bad

evaporation and get rid of this;

2 use new compressor;

Fan do not run

1 failure on fan relay

2 fan motor broken

1 replace the fan relay;

2 replace fan motor.

The compressor

runs but heat

pump has not

heating or

cooling capacity

1 no gas in the heat pump;

2 heat exchanger broken;

3 compressor failure.

1 check system leakage and recharge refrigerant;

2 find out the cause and replace the heat

exchanger;

3 replace compressor.

Low outlet water

temperature

1 low water flow rate;

2 low setting for the desired water temp.;

1 clean the water filter and discharge the air in

water loop.

2 reset the desired water temperature.

Low water flow

protection

1 lack of water in the system;

2 failure on flow switch

1 clean the water filter and discharge the air in

water loop.

2 replace the flow switch.

Maintenance

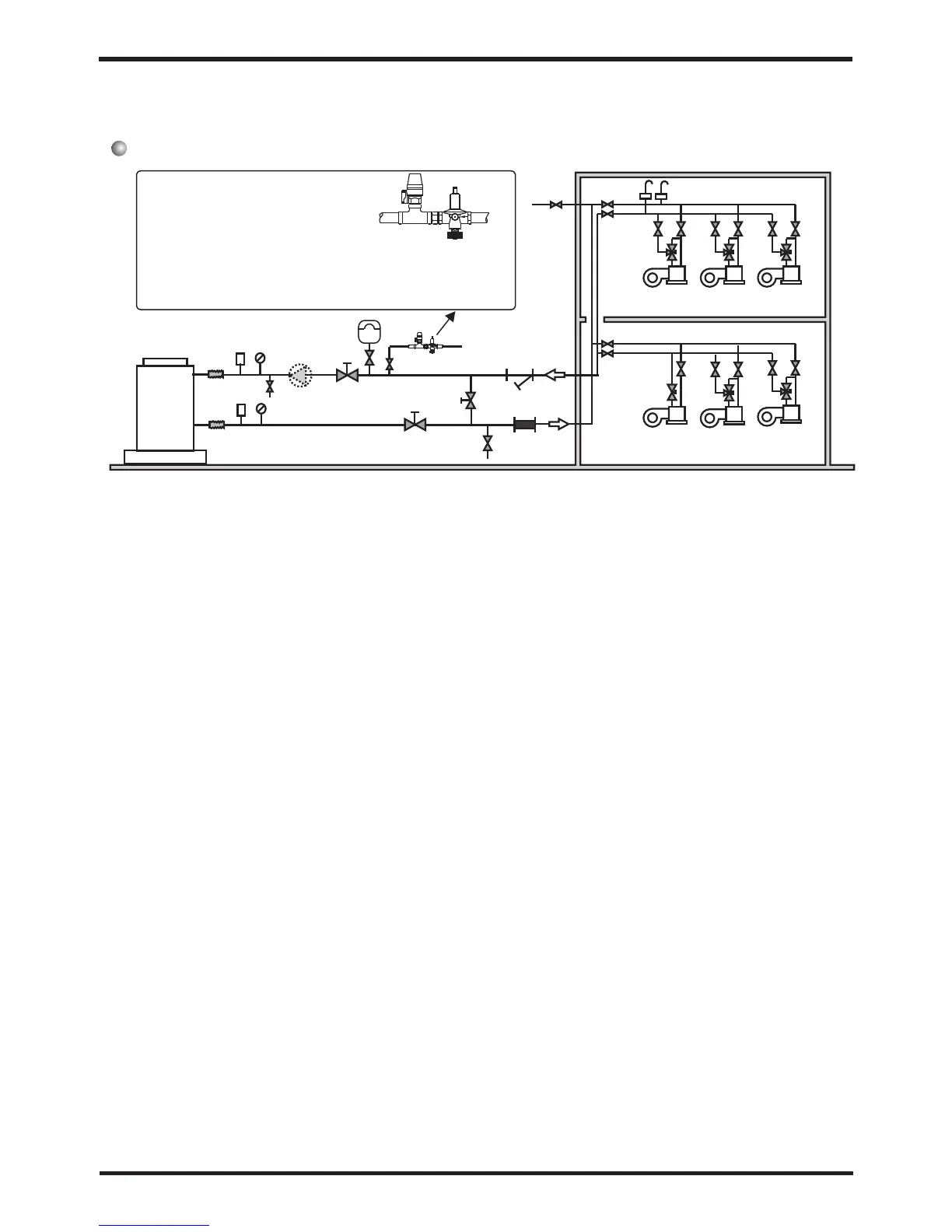

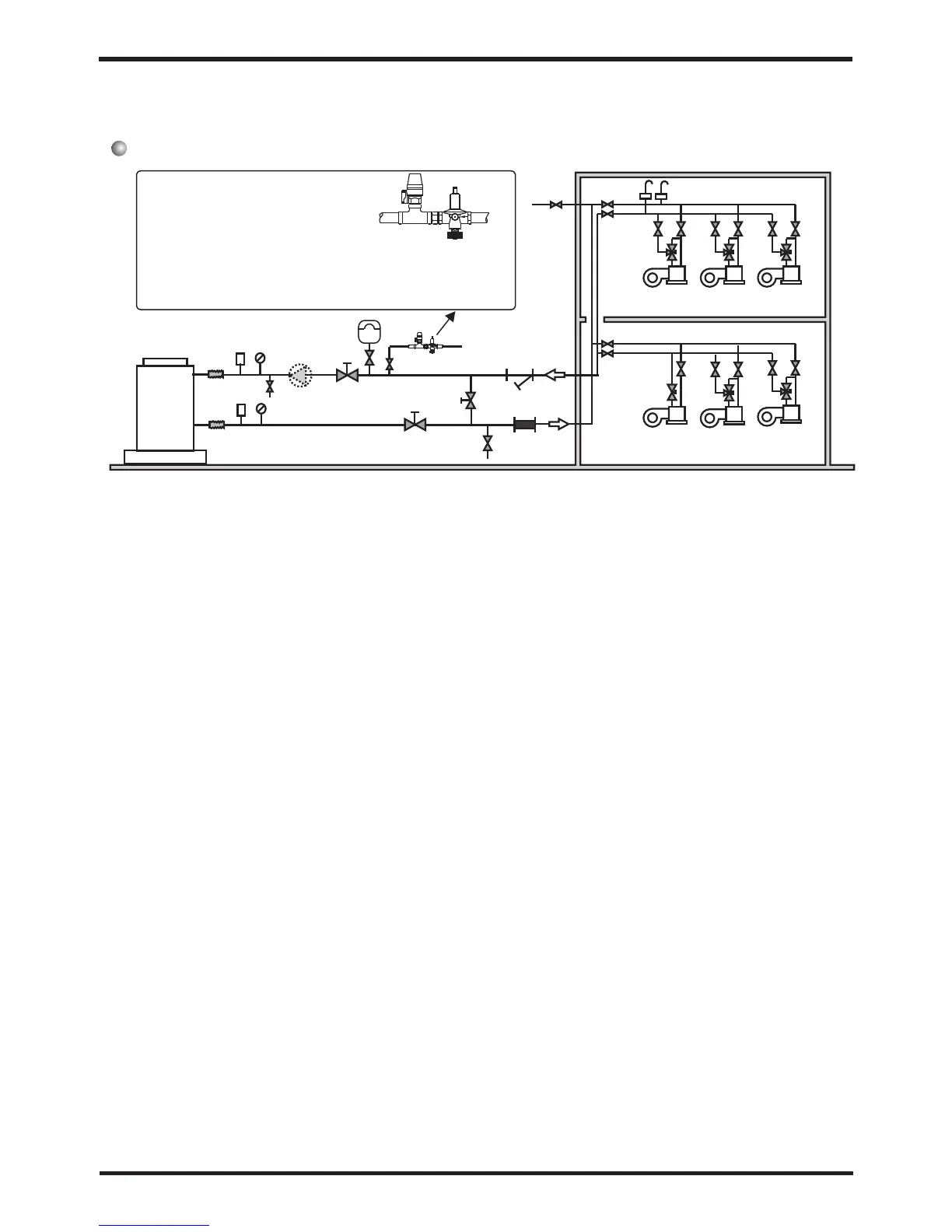

Especial installation( expandable water tank)

Appendix 1 Install sketch map

Appendix

Remark

1 main unit

2 fan coil

3 rubber flexible connection

4 thermometer

5 manometer

6 Y type filter

8 ball valve

10 bypass valve

1/2'

Technical request:

1.Each connection must be connected tightly and have no leakage.

2.the arrowhead orientation of automatic filled- water

must accord with water supply.

3.The pressure of automatic filled-water has been

set,and please do not remove screw.

automatic

fill-water

valve

Pressure

leakage

valve

2

1 4

1 5

1 3

1 7

Installation request:

1 The factory only offers main unit (1)in the legend, and the other modules

which are indispensable fittings, are provided by users or installation company.

2 The unit which of code contains the letter "B" ,has water pump inside and need

not install water pump outside (16)

3 Automatic ventilation(15)is installed on the top point of the water system。

4 The quantity proportion of two-way valve(13)and three-way valve(14)is

referred to the technical regulation, and there is three-way valve installed on the

farthest place of water system.

5 The ball valve (17) is used when it is swashed, filled water in the water system

and so on.

1

3

4

5

1 0

1 2

1 8

1 6

2 0

6

1 1

1 9

Connect supply pipe

1/2'

inlet

outlet

8

11 drain valve

12 filter

13 two-way valve

14 three-way valve

15 automatic ventilation

16 water pump

17 ball valve

18 ball valve

19 expandable water tank

20 automatically filled-water

20

21

Loading...

Loading...