5 Service

CAUTION: Servicing the Phoenix D385 with its high voltage

circuitry presents a health hazard which could result in

death, serious bodily injury, and/or property damage. Only

qualified service people should service this unit.

CAUTION-ELECTRICAL SHOCK HAZARD: Electrical power

must be present to perform some tests; these tests should

be performed only by a qualified service person.

Note: Check for airflow at all inlets and outlets. Do not run

unit if no airflow is detected.

5.1 Warranty

A warranty certicate has been enclosed with this unit;

read it before any repair is initiated. If a warranty repair is

required, call the factory rst at 1-800-533-7533 for warranty

claim authorization and technical assistance.

5.2 Technical Description

The D385 produces airow using two permanent split

capacitor (PSC) blower motors. A shaded-pole gear motor

rotates the desiccant rotor via a pulley and belt. Heat for

reactivation is generated by a two-stage nichrome heating

element powered by two separate branch circuits. The

heating elements cannot be energized individually – both

cords must be plugged in for them to operate. An LED

indicator lamp illuminates when the unit is powered on. An

hour meter also counts the cumulative hours the unit has

run.

The blowers, rotor motor, heating elements, indicator lamp,

and hour meter are operated by a line-voltage control circuit.

One branch circuit (Circuit 1) delivers power to the process

blower, indicator lamp, hour meter, and a 1270W heating

element through one relay (Relay 1). A separate branch

circuit (Circuit 2) delivers power to the reactivation blower,

rotor motor, and a 1360W heating element through a second

relay (Relay 2). Circuit 1 provides power to the coil for Relay

2 and Circuit 2 provides power to the Relay 1 coil. Because

of this latching between the two circuits, the unit cannot

operate unless both cords are plugged in. With both cords

plugged in, turning on the power switch energizes the Relay

2 coil. This energizes all of the loads on Circuit 2, as well as

the Relay 1 coil, which energizes all of the loads on Circuit 1.

If either cord is unplugged, all loads are de-energized.

Three thermal cutout switches allow for safe operation of

the D385. Two of these cutouts are located in the heater. If

the reactivation inlet temperature is too high or if there is

insufcient reactivation airow, the automatically-resetting

heater cutout opens and all loads are de-energized. Once

the temperature drops by a few degrees F, the switch

closes again and the loads are re-energized. The second

5

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

Reactivation air stream lter:

This 12”x12 x1” lter is located in the bottom of your D385.

To change the reactivation air lter, lay the D385 down in a

horizontal position. The lter access slot is located on the

bottom of the machine (Fig. 4). Open retainment clip, remove

old lter, and replace with fresh lter.

The stock lter supplied carries a MERV-7 ltration efciency

rating. This ltration prevents plugging the heater or loading

the desiccant wheel with foreign matter.

Operating the unit with a dirty lter will reduce the

dehumidier’s capacity and efciency and may cause the

heater coil to cut out on thermal overload.

The lter can generally be vacuumed clean several times

before needing replacement. Replacement lters can be

ordered from the factory or purchased locally if available.

DO NOT operate the unit without the lters or with less

effective lters as the desiccant wheel inside the unit will

become clogged and require disassembly to clean.

4.2 Blower Motors and Rotor Drive Motor

All motors on the D385 are permanently lubricated and do

not require maintenance.

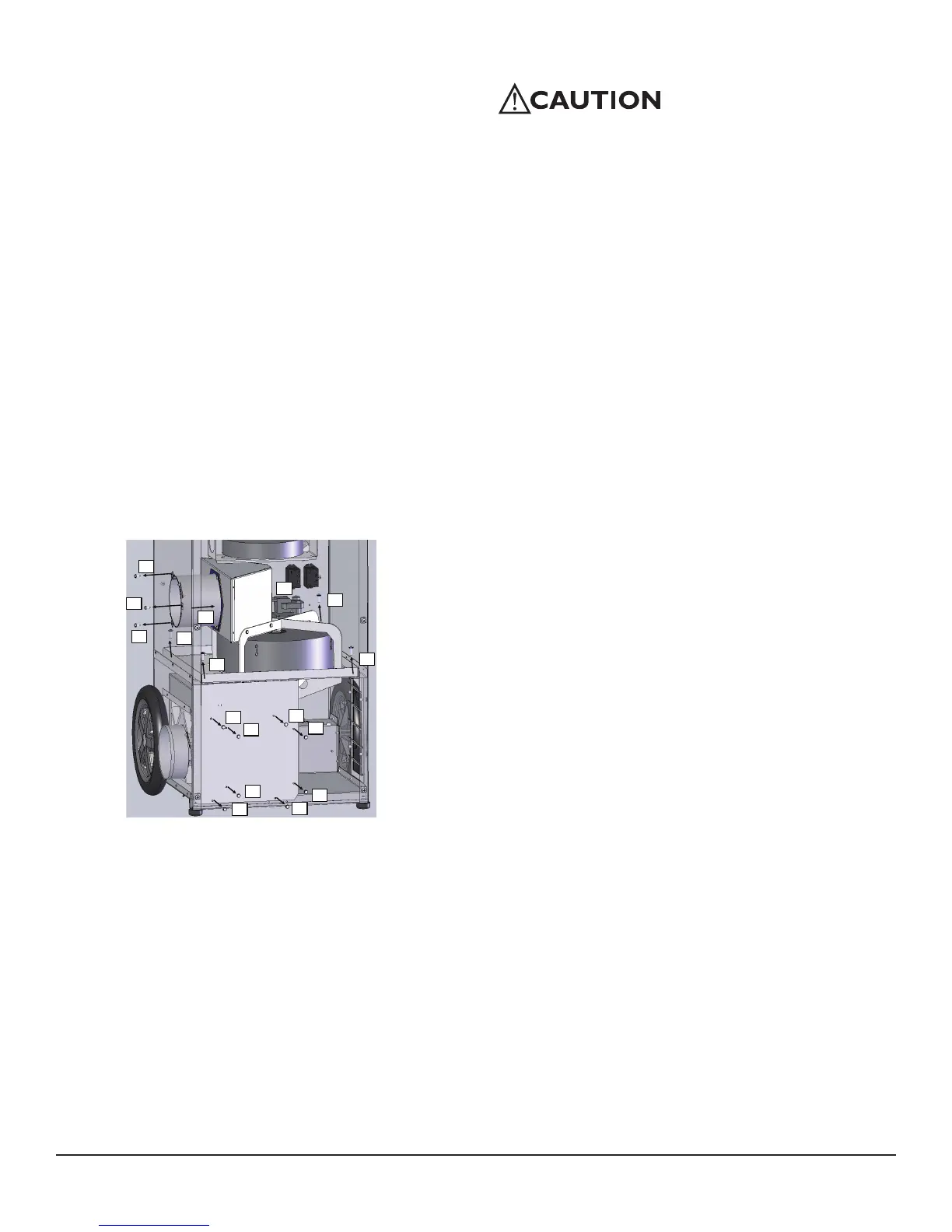

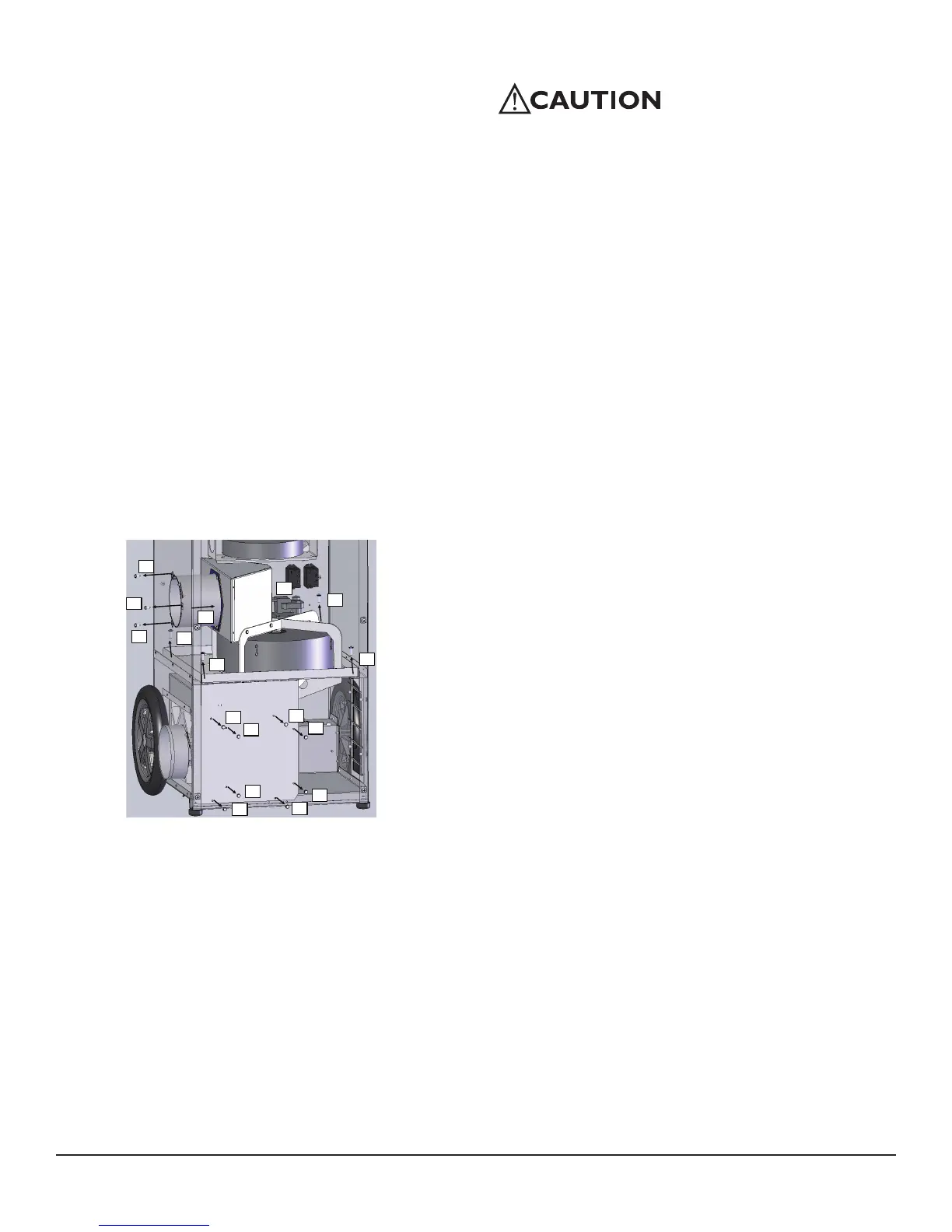

4.3 Desiccant Rotor Cassette Assembly

The cassette can be easily removed to inspect and/or clean

the seals and rotor. Reverse these steps to reinstall the

cassette.

PROCESS BLOWER

GRN 25

BLK 11

WHT 24

CORD 1 CORD 2

WHT WHTBLK

BLK

BLK

BRN

BLU 27

BLU

BLU

RED

RED

WHT 9

BLK 8

BLU 7

ORG 6

BLU

BLK

GRN

BLK

BLK

BLK

TERMINAL BLOCK

TERMINAL BLOCK

CIRCUIT 1 CIRCUIT 2

HEATER

THERM OL 1

176°F

HEATER

THERM OL 2

302°F

1360W

1270W

ROTOR MOTOR

1234

1234

REGEN CAPACITOR

REGEN BLOWER

PROC THERM

OL 140°F

MAIN POWER SWITCH

HOUR METER

PROC BLOWER PROC CAP

LIGHT

RELAY 1 RELAY 2

BLU 22

ORG 15

ORG 18

ORG 19BLU 21

BLU 20

ORG 6

ORG 15

ORG 12

ORG 28

BLK 1

ORG 14

BLK 17

BLK 11

BLK 10

BLK 10

BLU 27

WHT 4

BLK 8

BRN 5

BLK 3BLK

BLU

BRN

ORG 28

ORG 14

BLK 2

BLK 1

BLU 26

WHT 13

WHT 13

BLU 7

WHT 23

WHT 24

BLU 22

BLU 26

WHT 9

WHT 4

BLU 23

BLK 16BLK 3

BRN 5

BLK 2

WHT 23

1

2

3

4

LINE LINE

ROCKER

SWITCH POLE 1

ROCKER

SWITCH

POLE 2

NEUTRAL NEUTRAL

RELAY

CONTACT 1

1270W HEATER

1360W HEATER

HOUR METER

LAMP

HEATER

CUTOUT 1

RELAY COIL 2

PROCESS

CAPACITOR

HEATER

CUTOUT 2

PROCESS

CUTOUT

RELAY

CONTACT 2

REIGN

CAPACITOR

RELAY COIL 1

ROTOR MOTOR

REIGN BLOWER

BLU

BLK

BRN

BLU

BLK

BRN

Step 1: Remove three #10 screws holding reactivation duct in place

(1A, 1B, 1C) using 5/16” hex driver.

Push duct section (1D) in toward wheel

Step 2: Unplug wheel drive motor wires (2)

Step 3: Remove four ¼” screws holding cassette in place

(3A-3D) using #3 Phillips driver

Step 4: Remove eight #10 screws holding reactivation inlet cover in place

(4A-4H) using 5/16” hex driver. Remove reactivation inlet panel

Step 5: Lift cassette up and out of cabinet to avoid tearing

lower reactivation gasket

Step 6: Installation is reverse of removal

Cassette Removal Instructions

Loading...

Loading...