CIIEROKEE WARRIOR

In

jacking

the airplane

for landing

gear

or other service, two hydraulic

jacks

and

a tail stand

should

be

used. At least 250

pounds

of ballast should be

placed

on

the tailstand before

jacking

the airplane. The hydraulic

jacks

are

placed

under the

jack

points

on the

underside

of the wings,

and the

airplane

is

jacked

up until the tail stand can be attached to the tail

skid. After

attaching

the

tail

stand and adding

the

ballast,

the

jacking

can

be continued until the airplane

is at the

desired heieht.

The steering arrns

from

the rudder

pedals

to the nose

gear

are

adjusted at the rudder

pedals

or at the nose

wheel

by turning in or out the tlrreaded rod

end bearings.

Adjustments are

normally made at the forward end of the rods and should be

done in such a

way

that the

nose

wheel is in line with the fore and aft axis of the airplane

when the

rudder

pedals

and rudder are

centered. Alignment of

the nose wheel

can

be

checked

by

pushing

the airplane

back and

forth

with the rudder

centered

to determine that the

plane

follows

a

perfectly

straight line.

The turning arc of the

nose wheel is

30 degrees

either

side

of center and is

factory adjusted

at stops

on the bottom

of

the

forging. The turning radius of the

nose wheel is

l3

feet.

The rudder bar stops should be

carefully adjusted so that

the rudder

bar

reaches

its full

traveljust

after the rudder

hits

its stops.

This

guarantees

that the rudder

will be allowed

to move

through

its full

travel.

PROPELLER

SERVICE

The

spinner

and backing

plate

should be cleaned and

inspected

for

cracks

frequently.

Before each flight the

propeller

should be

inspected for nicks, scratches,

or corrosion.

If found,

they should be repaired as soon as

pssible

by a rated mechanic, since

a nick or scratch

causes

an

area of increased

stress which

can

lead to

serious

cracks or the

loss of a

propeller

tip.

The back

face

of the blades

should

be

painted

when necessary

with flat black

paint

to

retard

glare.

To

prevent

corrosion, all zurfaces

should be cleaned

and waxed

periodically.

OIL REQUIREMENTS

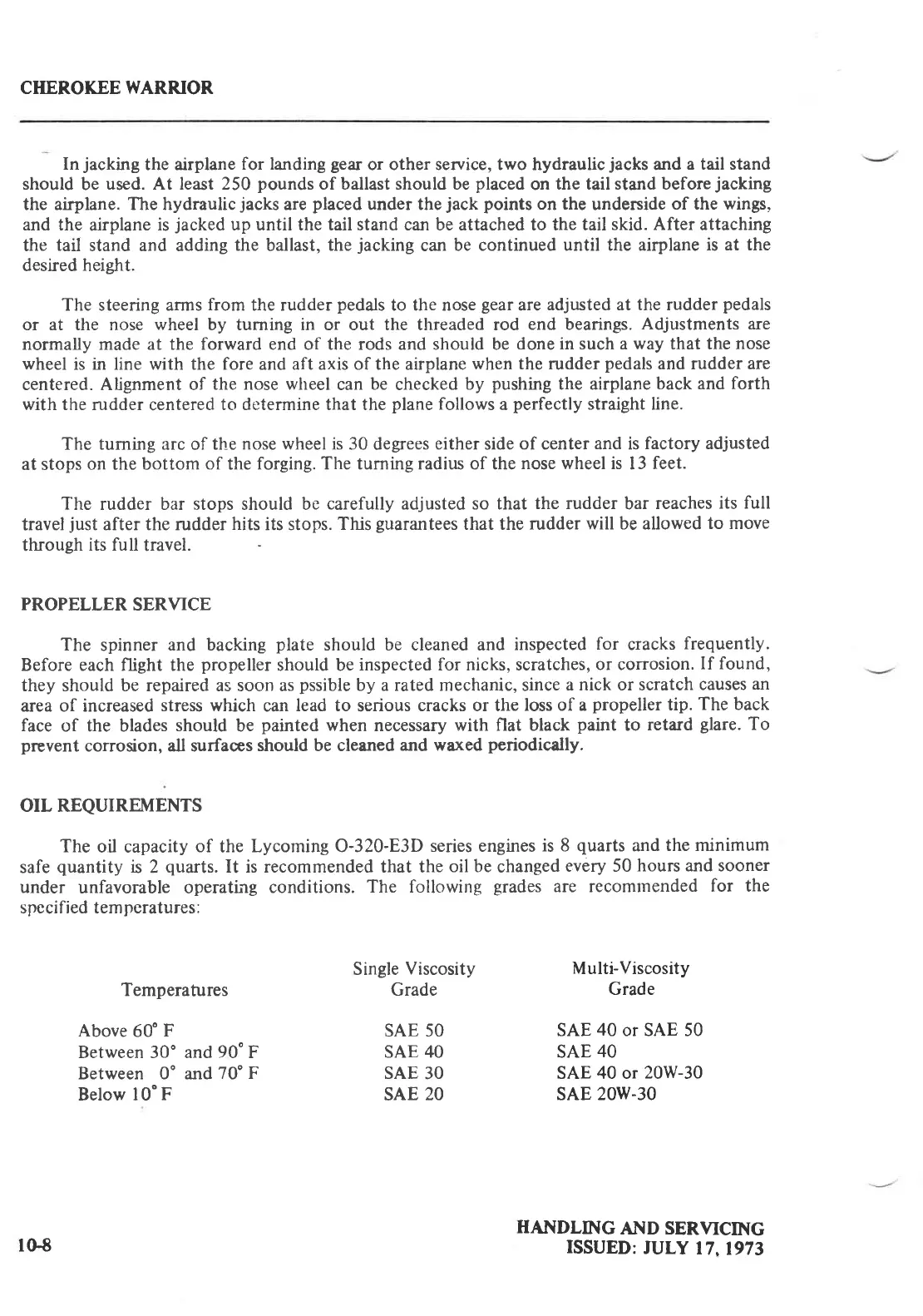

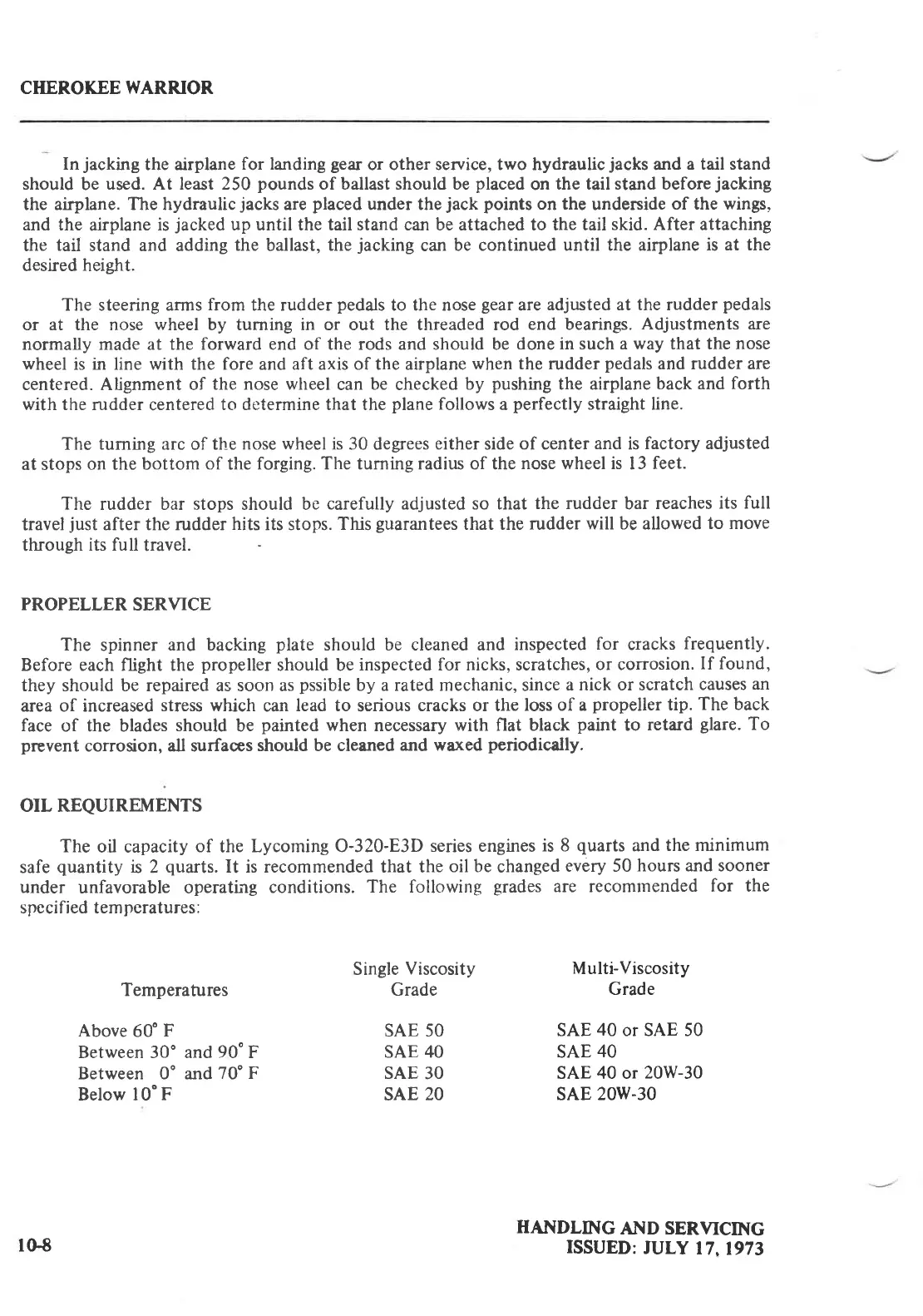

The

oil capacity

of

the

Lycoming O-320-E3D

series engines

is 8

quarts

and

the minimum

safe

quantity

is

2

quarts.

It is recommended that the

oilbe

changed

every 50

hours and sooner

under

unfavorable operating

conditions.

The following

grades

are recomrnended

for the

specified tem

peratures

:

Temperafures

Above

60"

F

Between 30' and

90"

F

Between 0" and

70" F

Below l0'F

Single

Viscosity

Grade

SAE 50

SAE 40

SAE

30

SAE

20

Multi-Viscosity

Grade

SAE

40

or SAE 50

SAE

40

SAE 40 or

20W-30

sAE 20W-30

HANDLING

AT{D SERVICING

ISSUED:

JULY

17,1973

lo{

Loading...

Loading...