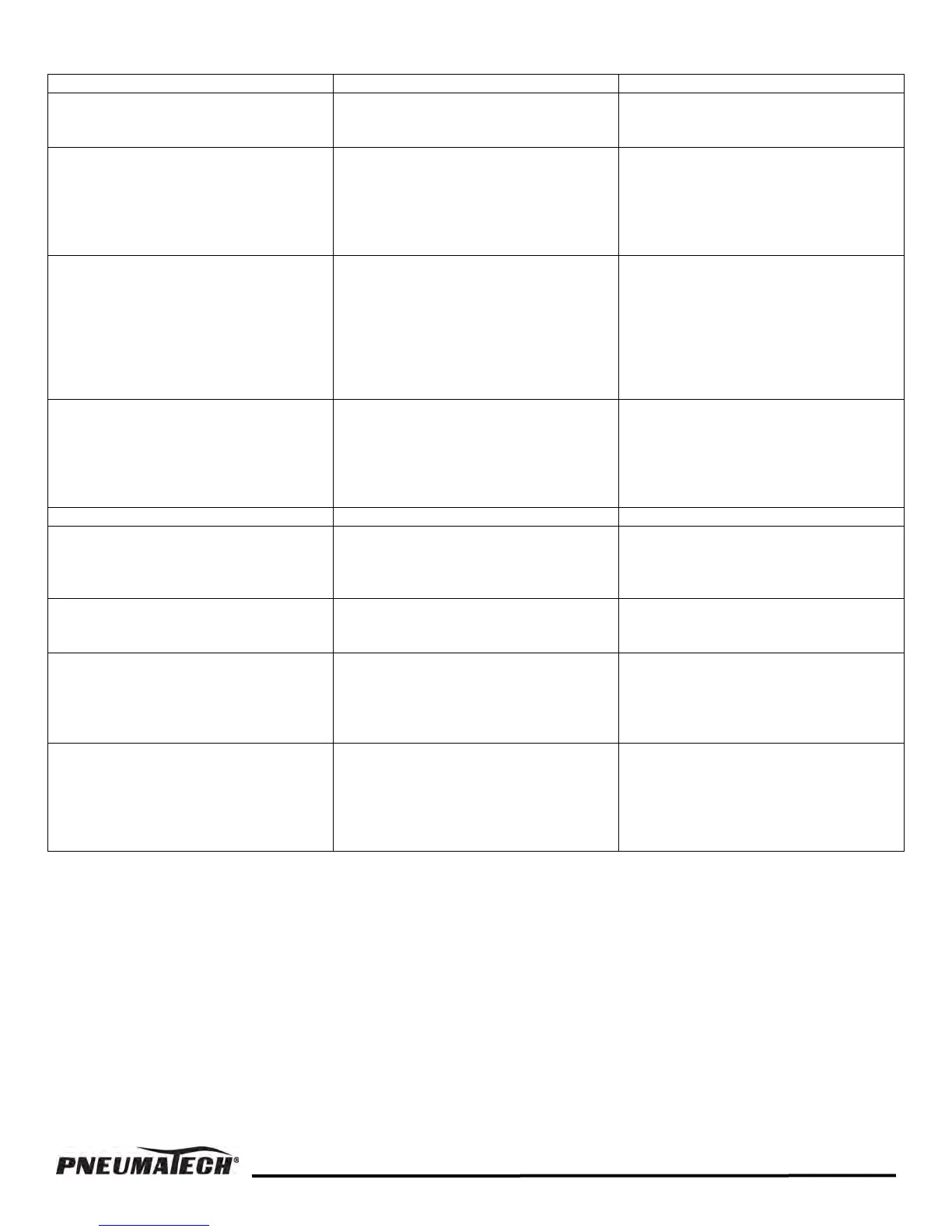

Table 1 — Troubleshooting Guide for PH Series Heatless Regenerative Dryers, continued

Symptoms Cause Remedy

D. No gas flow through the dryer. 1. Both inlet valves closed due to low

inlet pressure.

1. Manually open the inlet valve by

turning the shaft or the ON

actuator.

E. Failure to switch alarm light. 1. Inlet valves did not switch.

2. Faulty timer.

3. Insufficient pilot air pressure.

4. Cylinder leaking or seized up.

1. Check pilot air solenoid valve.

Repair if necessary.

2. Replace timer.

3. Clean or replace pilot filter

element.

4. Repair or replace pilot air cylinder.

F. High pressure drop in dryer. 1. Desiccant retainer screens

plugged.

2. Excess flow.

3. High purge flow.

4. Purge valve stays open.

5. Repressurizing valve stays open.

1. Replace desiccant retainer

screens.

2. Check inlet flow conditions.

3. Check and reset purge pressure.

4. Check repressurizing solenoid

valve, repair or replace if

necessary. Check timer.

5. See C4.

G. Dryer fails to purge. 1. Orifice plate plugged.

2. Purge valve fails to open.

3. Purge valve closed.

4. Purge check valve blocked.

1. Clean the orifice plate.

2. See F3.

3. Reset proper purge pressure.

4. Inspect purge check valve.

Replace if necessary.

H. High dewpoint alarm light. See chart on alarm conditions.

I. Moisture indicator color turned

translucent (wet conditions).

1. Bleed valve closed.

2. See probable cause on #1.

1. Open the bleed valve to allow

small amount of air to constantly

flow through the gel.

J. Tower fails to pressurize. 1. Purge valve stays open.

2. Repressurizing valve faulty.

1. See F3.

2. See C4.

K. Tower does not pressurize fully. 1. Inlet pressure low.

2. Purge pressure too low.

3. Repressurizing period too short.

1. Calibrate and plot purge pressure

and reset.

2. Reset proper purge pressure.

3. Check timer sequence of

operation.

L. Excess desiccant dust.

NOTE: If the regenerating tower does

not pressurize fully, desiccant attrition

takes place at the time of tower

switchover.

1. See J & K.

2. Excess flow due to greater demand

in process or addition of extra

compressors.

2. Check outlet flow.

21

Loading...

Loading...