22

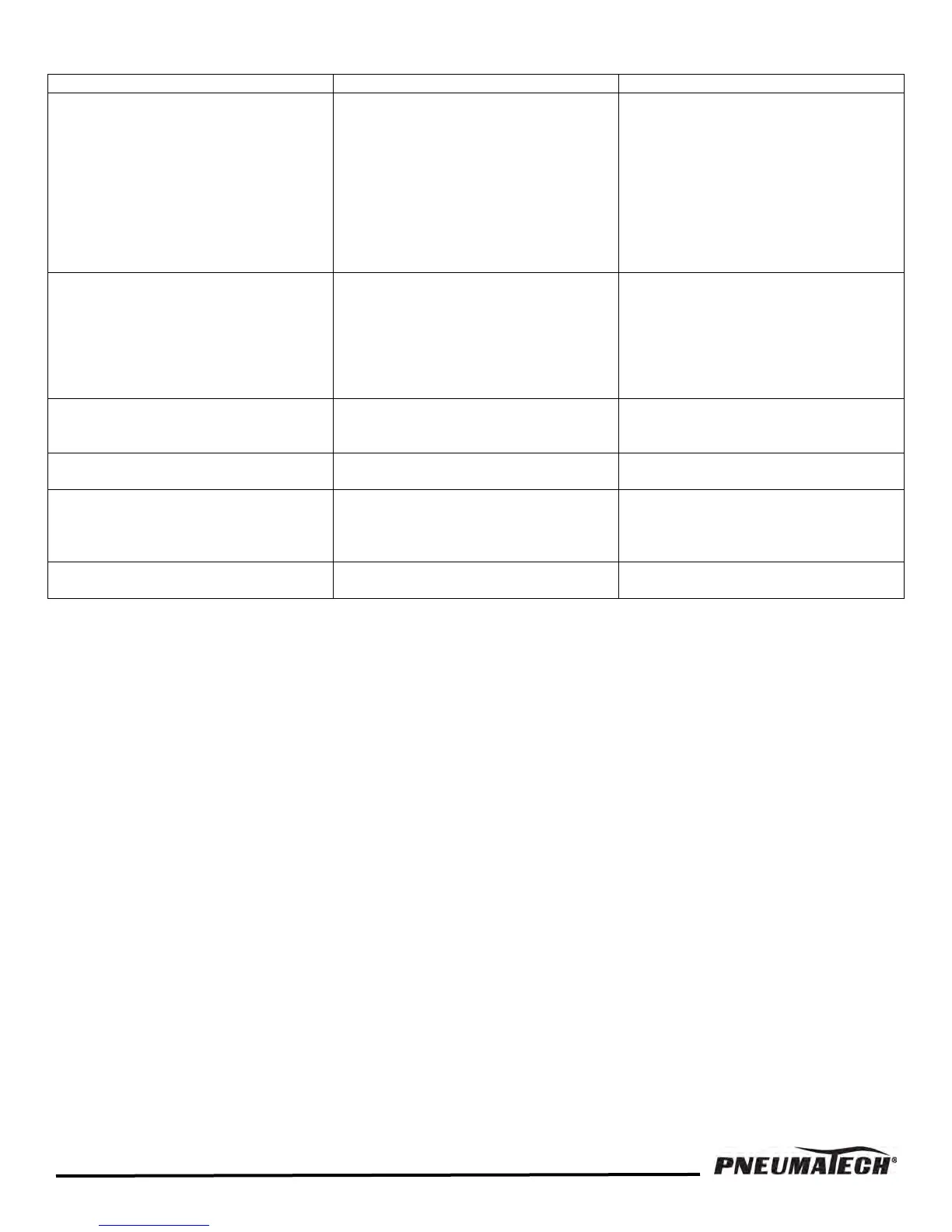

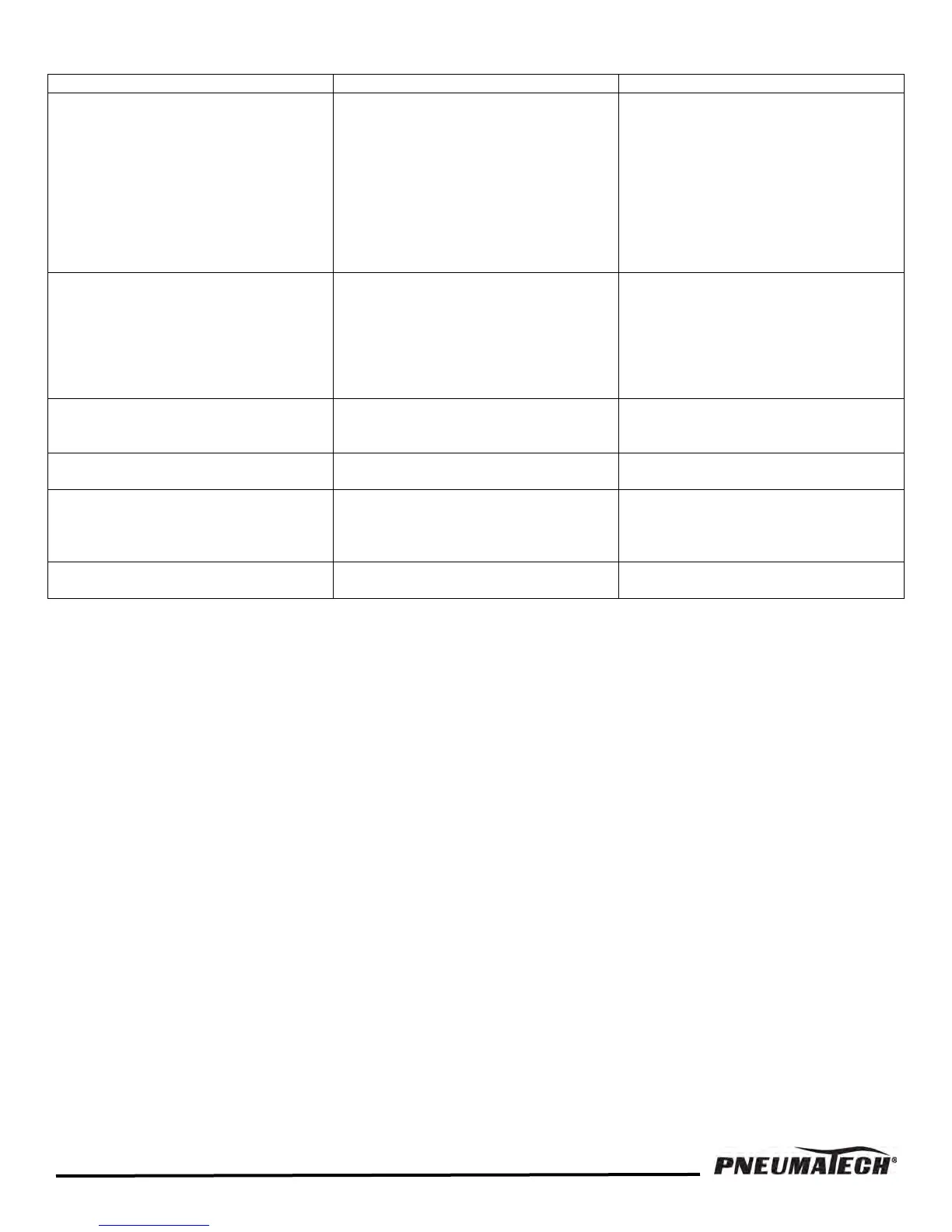

Table 2 — Troubleshooting Guide for PHM Mini Series Heatless Regenerative Dryers

Symptoms Cause Remedy

A. Elevated Dewpoint 1. Low inlet pressure.

2. Excess moisture carryover.

3. Excess gas inlet flow.

4. Desiccant coated with oil.

5. Low inlet air temperature.

1. Increase pressure (minimum 75

PSIG), or reduce flow.

2. Check drains at aftercooler and

prefilter.

3. Check the total output of

compressors.

4. Depressurize the dryer and

replace the desiccant.

5. Raise inlet temperature above

75°F (24°C).

B. High back pressure on

regenerating tower.

NOTE: The tower should be at ‘0’

PSIG during regeneration cycle.

Any back pressure will result in

improper regeneration.

1. Muffler plugged.

2. Shuttle valve leaking.

1. Replace mufflers.

2. Clean, repair or replace faulty

valve.

C. Excessive flow through mufflers. 1. Check valves sticking.

2. Purge valve sticking.

3. Timer short-circuited.

1. Clean, repair or replace valve.

2. Clean, repair or replace valve.

3. Replace faulty timer.

D. Failure to switch. 1. Inlet valves did not switch.

2. Timer short-circuited.

1. Clean, repair or replace valve.

2. Replace faulty timer.

E. High pressure drop in dryer. 1. Desiccant retainer screens

plugged.

2. High purge flow.

3. Purge valve stays open.

1. Replace desiccant retainer

screens.

2. See. C1 to C3.

3. Clean, repair or replace valve.

F. Dryer fails to purge. 1. Orifice plate plugged.

2. Purge valve stuck closed.

1. Clean the orifice plate.

2. Clean, repair or replace valve.

Loading...

Loading...