GENERAL INFORMATION

2.31

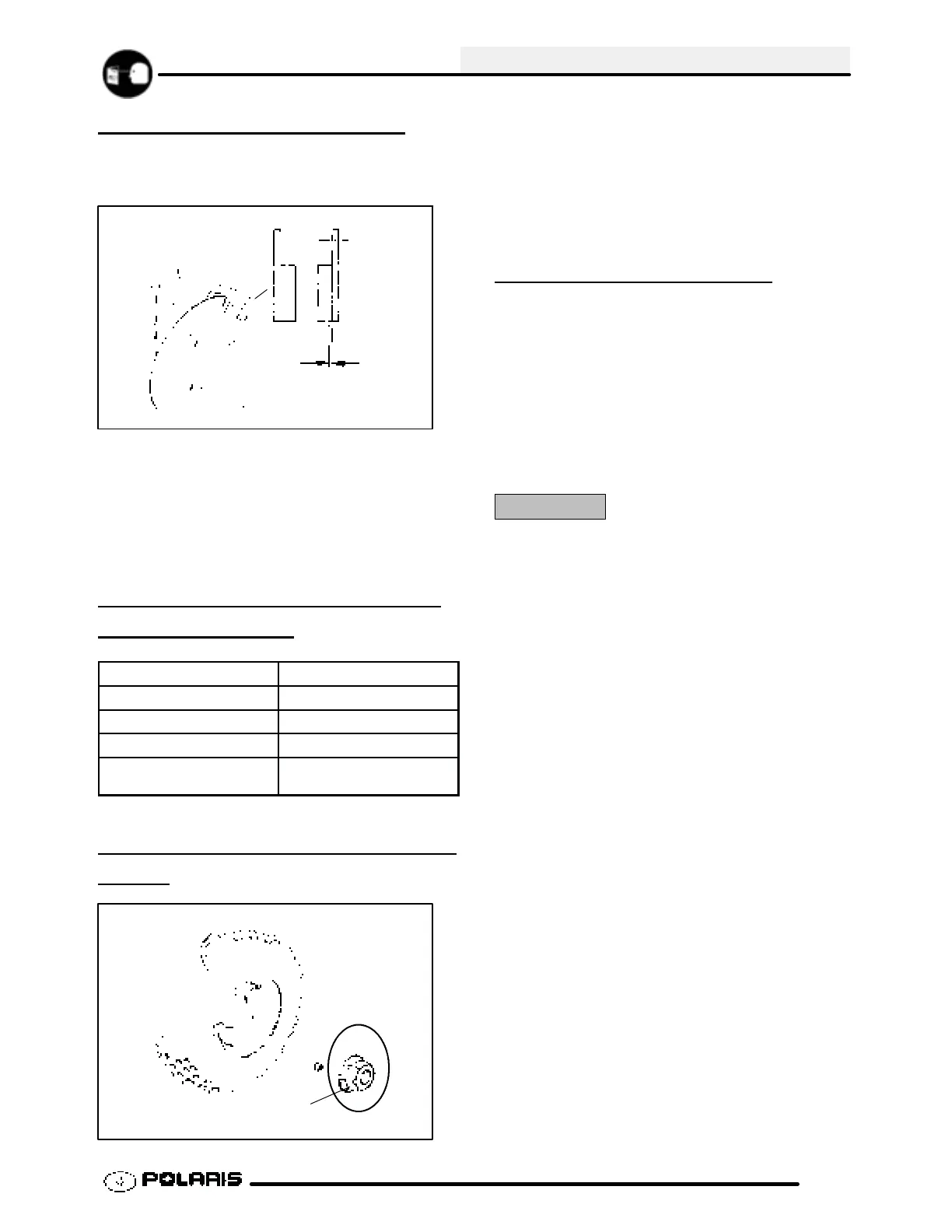

BRAKE PAD INSPECTION

Pads should be changed when the friction material is

wornto3/64² (.1 cm), or about the thickness of a dime.

3/64²

(.1cm)

Minimum

Thickness

Hose/Fitting Inspection

Check brake system hoses and fittings for cracks,

deterioration, abrasion, and leaks. Tighten any loose

fittings and replace any worn or damaged parts.

WHEEL, HUB, AND SPINDLE

TORQUE T

ABLE

Item Specification

Front Wheel Nuts 35 Ft. Lbs. (47 Nm)

Rear Wheel Nuts 35 Ft. Lbs. (47 Nm)

Front Spindle Nut 40 Ft. Lbs. (55 Nm)

Rear & Center Hub Retain-

ing Nut

110 Ft. Lbs. (150 Nm)

WHEEL REMOVAL FRONT OR

REAR

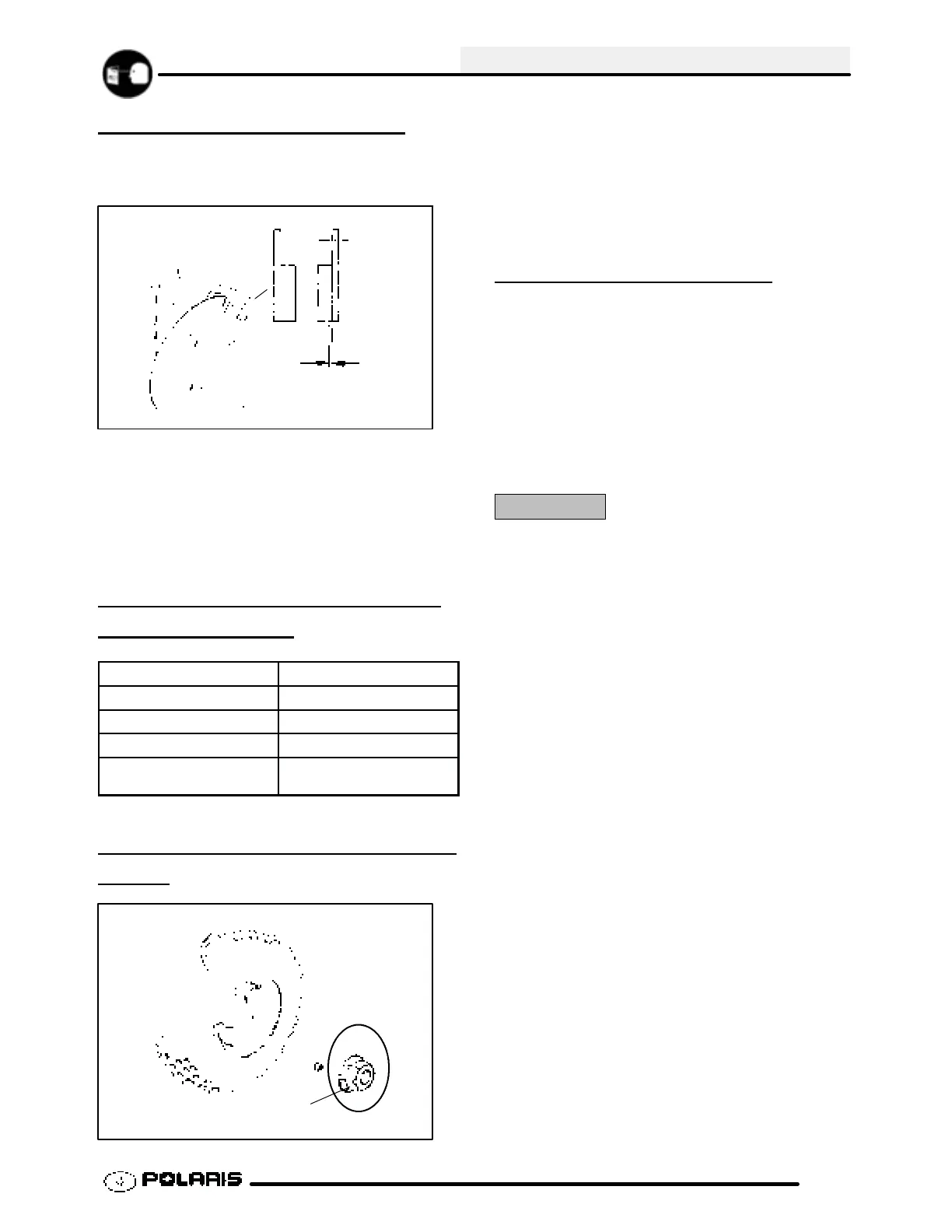

Flange Nuts:

Flat side against wheel

1. Stop the engine, place the transmission in gear

and lock the parking brake.

2. Loosen the wheel nuts slightly.

3. Elevate the side of the vehicle by placing a

suitable stand under the footrest frame.

4. Remove the wheel nuts and remove the wheel.

WHEEL INSTALLATION

1. With the transmission in gear and the parking

brake locked, place the wheel in the correct

position on the wheel hub. Be sure the valve stem

is toward the outside and rotation arrows on the

tire point toward forward rotation.

2. Attach the wheel nuts and finger tighten them.

3. Lower the vehicle to the ground.

4. Securely tighten the wheel nuts to the proper

torque listed in the table above.

CAUTION:

If wheels are improperly installed it could affect

vehicle handling and tire wear . On vehicles with

tapered rear wheel nuts, make sure tapered end of nut

goes into taper on wheel.

Loading...

Loading...