BELT INSPECTION

To inspect the drive belt, do the following:

1. Inspect belt for hour-glassing (extreme circular wear in at least one spot and

on both sides of the belt). Hour glassing occurs when the drive train does not

move and the drive clutch engages the belt.

2. Inspect belt for loose cords, missing cogs, cracks, abrasions, thin spots, or

excessive wear. Compare belt measurements with a new drive belt. Replace

if necessary.

3. Belts with thin spots, burn marks, etc., should be replaced to eliminate noise,

vibration, or erratic PVT operation.

BELT INSTALLATION

NOTICE

Be sure to install belt in the same direction as it was removed.

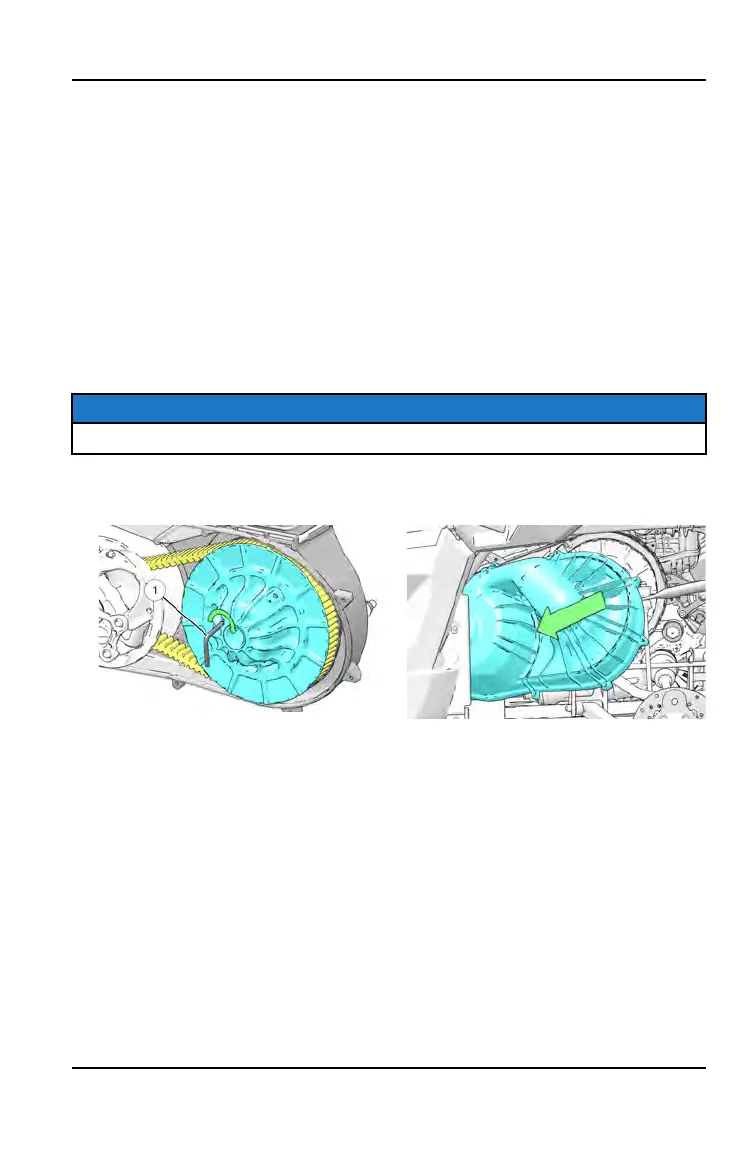

1. With the clutch spreader tool

q

installed, loop the belt over the drive clutch

and over the driven clutch.

2. Rotate the driven clutch and walk the belt into the clutch.

3. Remove the clutch spreader tool from driven clutch.

4. Rotate / spin the driven clutch and belt approximately 5-7 times to properly

seat the belt in the driven clutch.

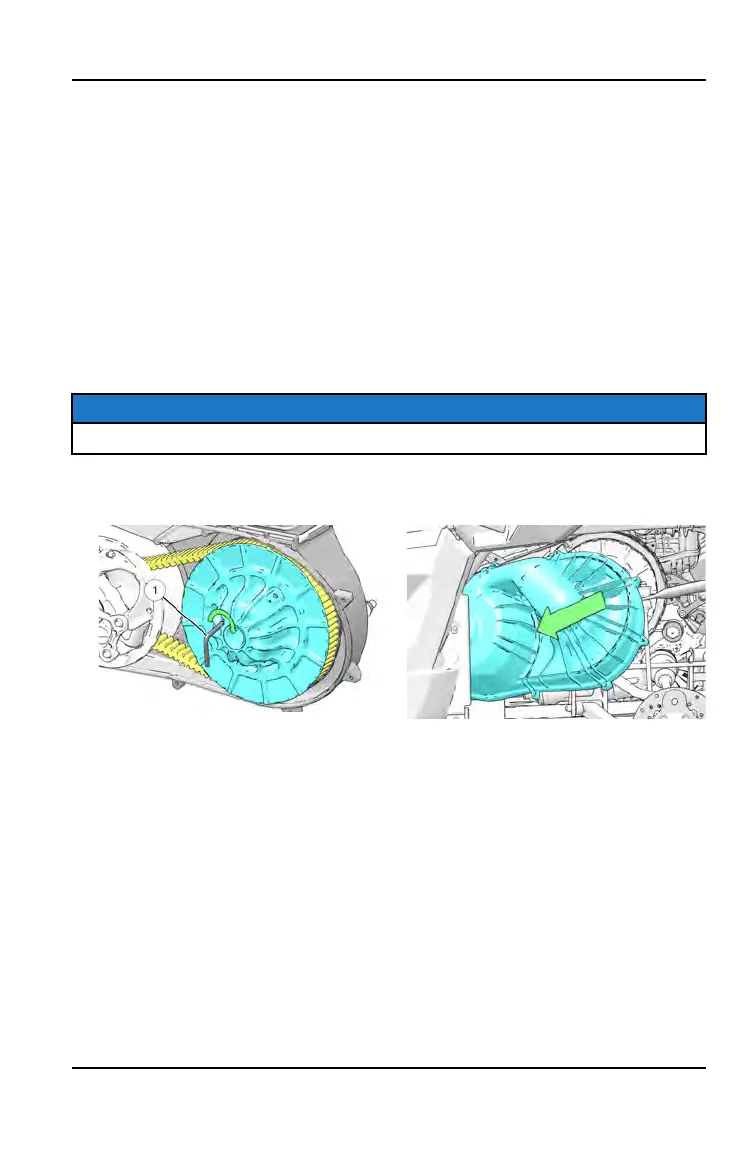

5. Install the clutch cover into wheel well as shown above.

6.

Rotate clutch cover over A-Arm

w

as shown below. Use care not to damage

intake boots or electrical harness.

131

MAINTENANCE

Loading...

Loading...