13

The speed and depth of cut will depend

largely on the type of material being

worked upon. Keep the cutting pressure

constant but do not crowd the router so

the motor speed slows excessively. It

may be necessary on exceptionally hard

woods or problem materials to make

more than one pass at various settings to

get the desired depth of cut.

When making cuts on all four edges of

the workpiece, it is advisable to have the

first cut on the end of the piece across the grain. Thus, if chipping of wood

occurs at the end of a cut, it will be removed when making the next cut

parallel with the grain.

Periodically wipe columns clean with a dry cloth. DO NOT lubricate columns.

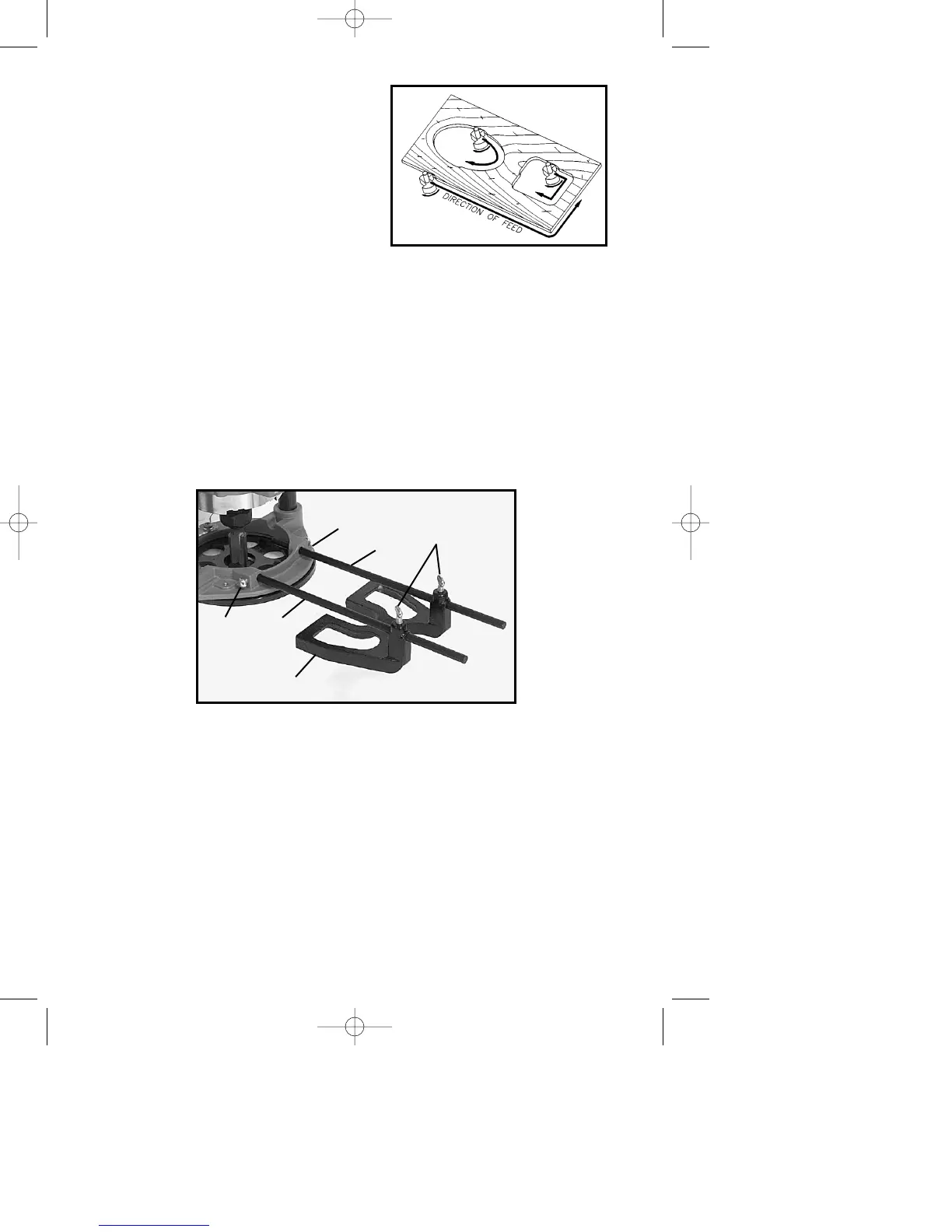

THE EDGE GUIDE

An edge guide is available as an accessory to aid in routing operations such

as: straight edge planing, parallel grooving, dado or slotting operations.

To assemble, insert guide rods (A) in holes in base, Fig. 18, and secure with

screws (B). The guide (C) is adjusted on the rods and secured in desired

position with thumb screws (D).

TEMPLET GUIDES

A wide variety of templet guides are available for use in pattern and templet

routing operations, Fig. 19 shows a typical combination bit, templet guide,

and locknut.

CAUTION: DISCONNECT TOOL FROM POWER SOURCE.

To install, insert templet guide in center hole in router base and secure in

place with the locknut.

BEFORE CONNECTING ROUTER TO POWER SOURCE. Install bit, adjust

depth of cut, and rotate router chuck by hand to be sure bit or collet do not

contact templet guide.

Fig. 17

Fig. 18

B

B

A

A

C

D

Loading...

Loading...