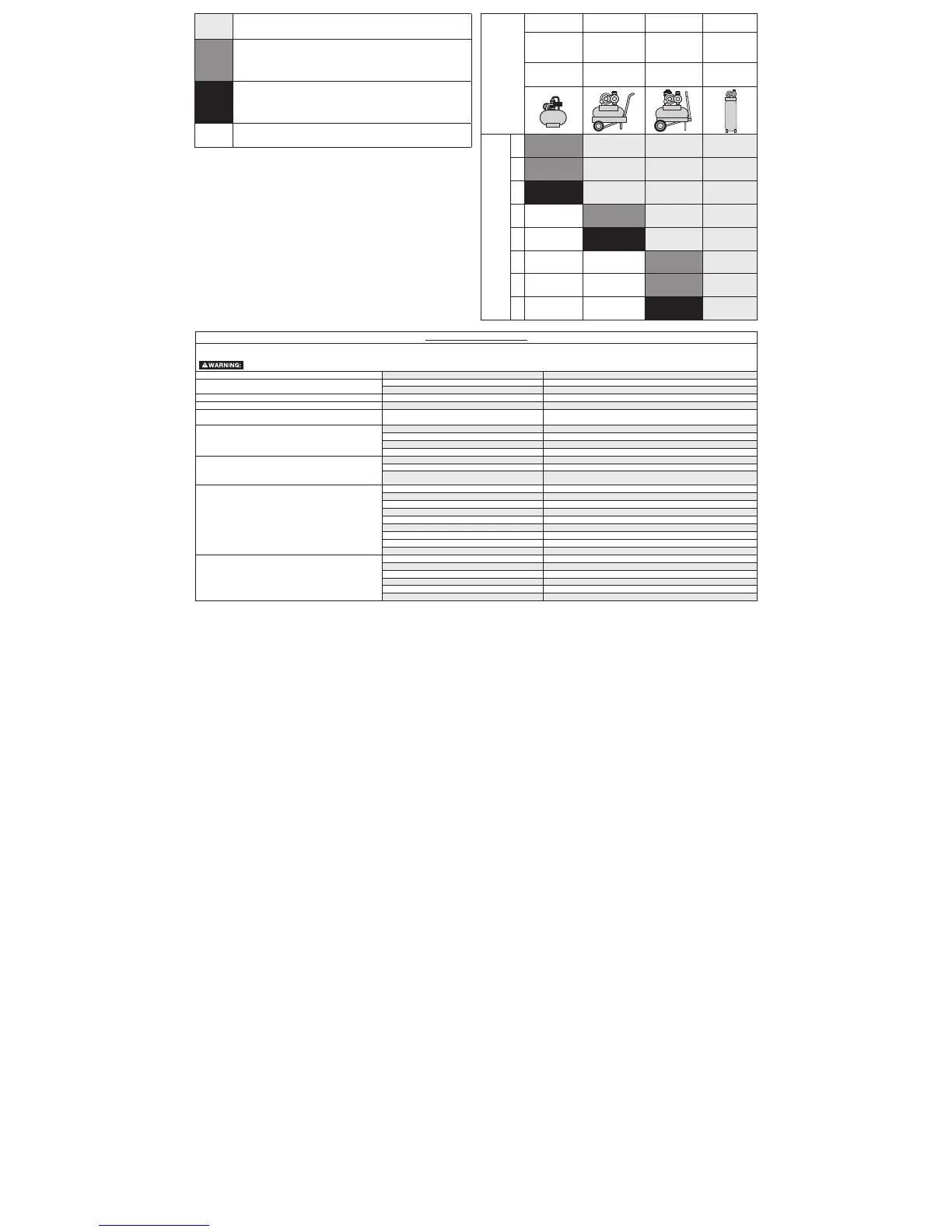

Compressor will be sufficient for tools at all production rates.

Compressor will be sufficient at slow or moderate production rates, but may have difficulty at

very rapid rates.

Compressor will be adequate only when tools are utilized at slow production rates (punch-out

or occasional use).

NR

Not Recommended

Portable Handcarry

3.2 – 4 CFM

5.5 HP Gas 2 HP Elec.

8 – 9 CFM

8 HP Gas

14 – 16 CFM

Industrial

23+ CFM

5,4 – 6,8 CMM

(3,2 – 4 CFM)

13,6 – 15,3 CMM

(8 – 9 CFM)

23,8 – 27,2 CMM

(14 – 16 CFM)

39,1+ CMM

(23+ CFM)

5,4 – 6,8 CMM

(3,2 – 4 CFM)

13,6 – 15,3 CMM

(8 – 9 CFM)

23,8 – 27,2 CMM

(14 – 16 CFM)

39,1+ CMM

(23+ CFM)

NUMBER OF TOOLS CONNECTED TO COMPRESSOR

1

2

3

4

NR

5

NR

6

NR NR

7

NR NR

8+

NR NR

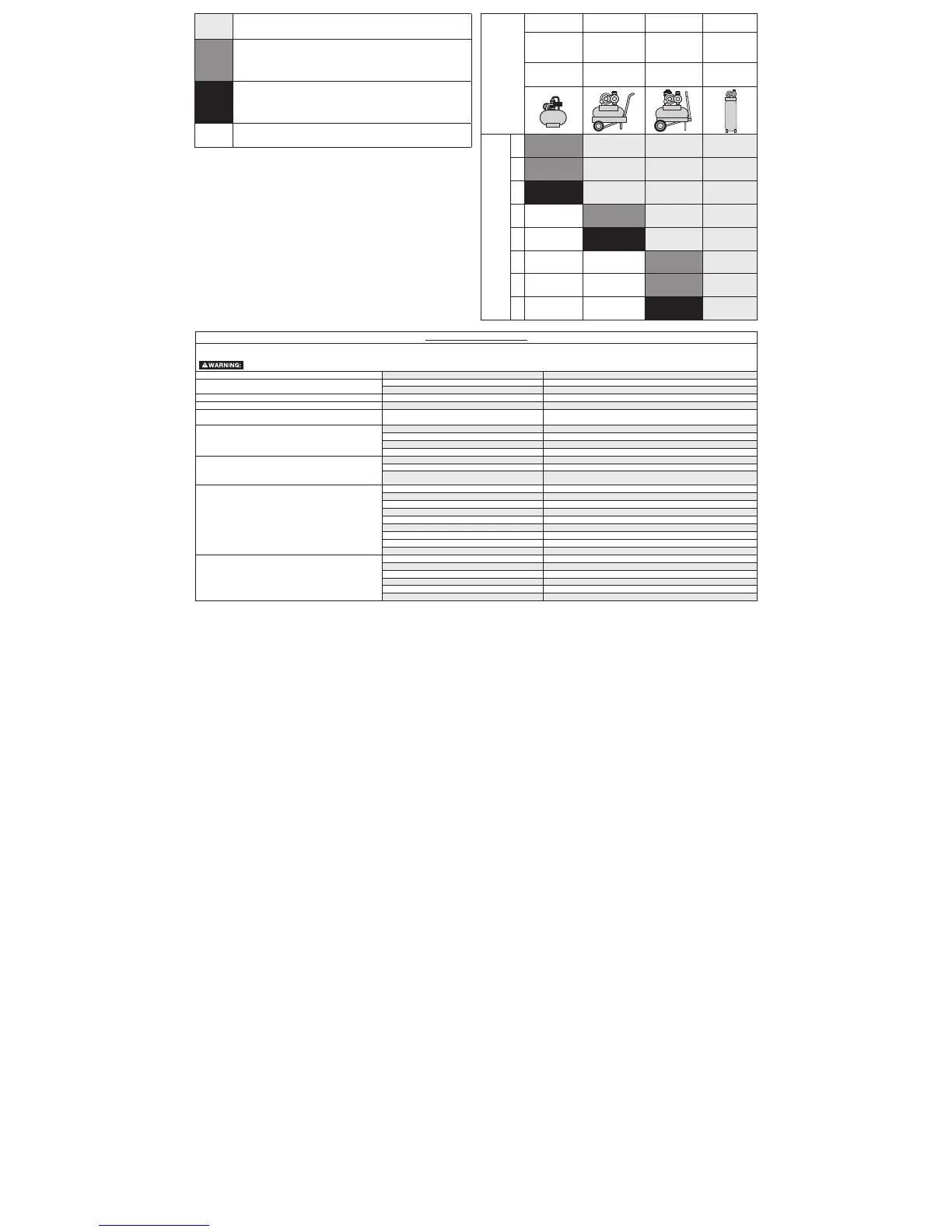

TROUBLESHOOTING GUIDE

Trigger valve housing leaks O-ring or valve stem failure Replace valve using: Trigger Valve Kit

Top cap leaks air Loose cap screws Tighten cap screws using appropriate hex wrench

Damaged or worn gasket or o-ring Replace gasket/o-rings using: O-ring Repair Kit

Exhaust leaks Main seal or o-ring damaged, debris in tool Replace gasket/o-rings using: O-ring Repair Kit

Air leaks around nose when tool is at rest (Driver blade in up position) Damaged or worn o-rings Replace gasket/o-rings using: O-ring Repair Kit

Air leaks around nose when tool is in actuated position

(Driver blade in down position)

Damaged or worn bumper Replace bumper using: Bumper Kit

Tool does not cycle in cold weather Tool not receiving air Check air supply

Valve may be frozen Warm up tool

Damaged or worn o-rings Replace gasket/o-rings using: O-ring Repair Kit

Broken or damaged driver blade Replace Driver Blade Kit

Lack of power; sluggish Low air pressure Check air supply

Damaged or worn o-rings Replace gasket/o-rings using: O-ring Repair Kit

Exhaust port blocked or clogged Disconnect the tool from the air supply, remove exhaust plate from top of tool, clean

port

Skipping fasteners; intermittent feed Air restricted Check air supply and couplers

Nosepiece screws loose Tighten nosepiece screws using appropriate hex wrench

Wrong size/angle fasteners Use only recommended fasteners

Dirty magazine Clean magazine track and nosepiece

Worn magazine Replace magazine

Broken or damaged driver blade Replace Driver Blade Kit

Trigger valve o-ring worn or damaged Replace valve using: Trigger Valve Kit

Worn or damaged pusher spring Replace spring

Magazine loose Check that magazine latch is holding firmly

Fasteners jam in tool Driver channel in nose piece worn Replace nosepiece

Wrong size/angle fasteners Use only recommended fasteners

Magazine loose Check that magazine screws are holding firmly

Worn driver blade Replace Driver Blade Kit

Nosepiece screws loose Tighten nosepiece screws using appropriate hex wrench

Fasteners not feeding properly Ensure fasteners are feeding properly into nose

Loading...

Loading...