Page No. 7

Issue Date: Rev 14 28 May 2012

Operating Instructions Form No. 102842

SET-UP

1. Hydraulic Connections

IMPORTANT

Seal all hydraulic connections with a high grade, nonhardening thread sealant. PTFE tape

may also be used to seal hydraulic connections if only one layer of tape is used. Apply the

tape carefully, two threads back, to prevent it from being pinched by the coupler and broken

off inside the pipe end. Any loose pieces of tape could travel through the system and ob-

struct the ow of uid or cause jamming of precision t parts.

A. Clean all areas around the uid ports of the pump and cylinder. Clean all hose ends, cou-

plers, and union ends. Remove thread protectors from the hydraulic uid outlets, and con-

nect the hose assembly. Couple hose to cylinder.

B. The use of a hydraulic pressure or tonnage gauge (not included) is strongly recommended.

Remove the pipe plug from the gauge port of the valve, thread the gauge into this port and

seal as noted above.

WARNING

To help prevent personal injury,

• The gauge must have the same pressure rating as the pump and cylinder. Personal in-

jury can result if the wrong gauge is used.

• Release hydraulic pressure BEFORE removing or tightening hose couplings.

OPERATION

The P460 can be operated only in the horizontal position. All other hand pumps can be operated

in a horizontal position or in a vertical position with head pointing downward. Refer to Table 1 and

your pump name plate to determine your style of pump.

IMPORTANT

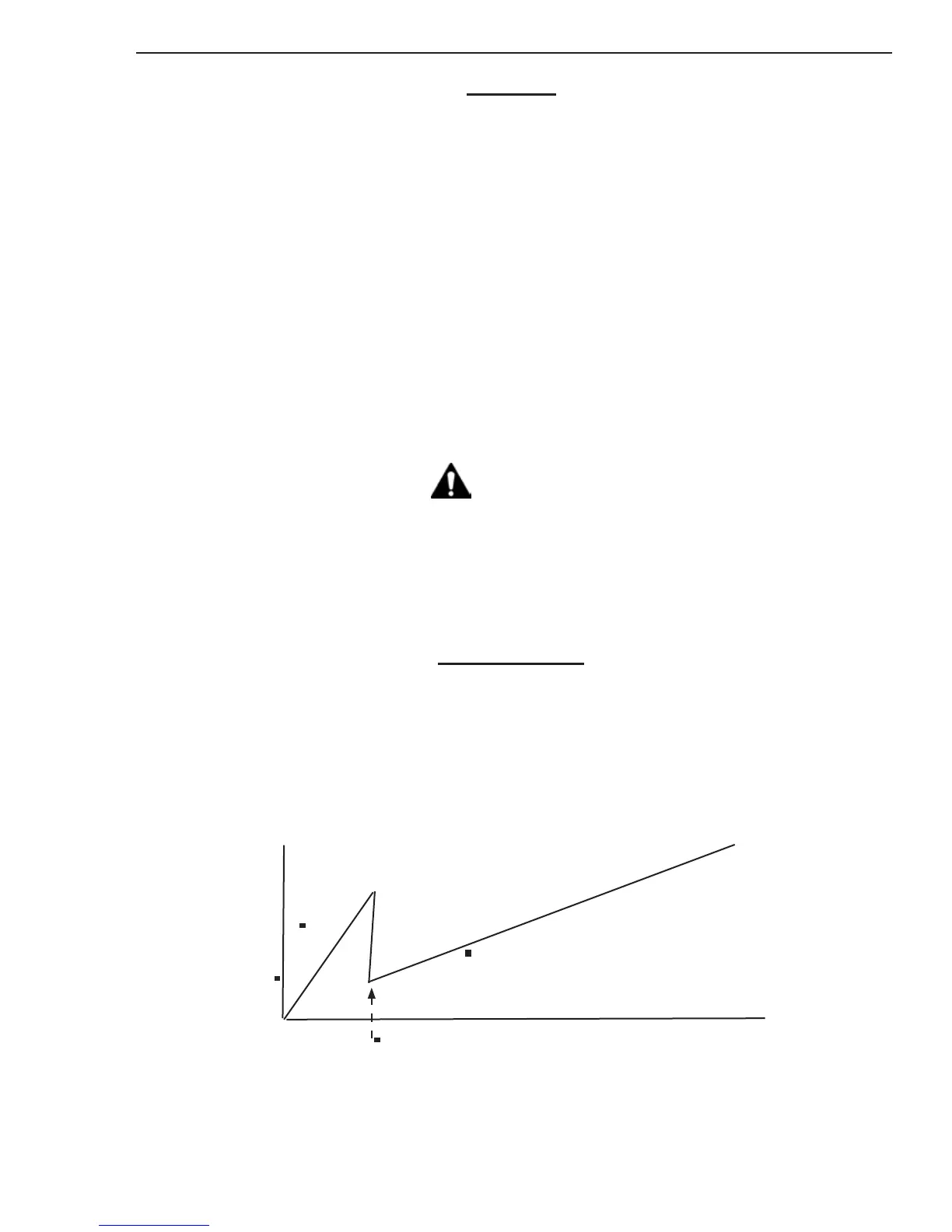

Figure 1 illustrates the normal drop of handle effort experienced when all (except P59) two-

stage pumps shift from low pressure stage to high pressure stage.

Handle Effort

Low Pressure Stage

High Perssure Stage

Unloading

Pressure

Pressure

Figure 1

Loading...

Loading...