19

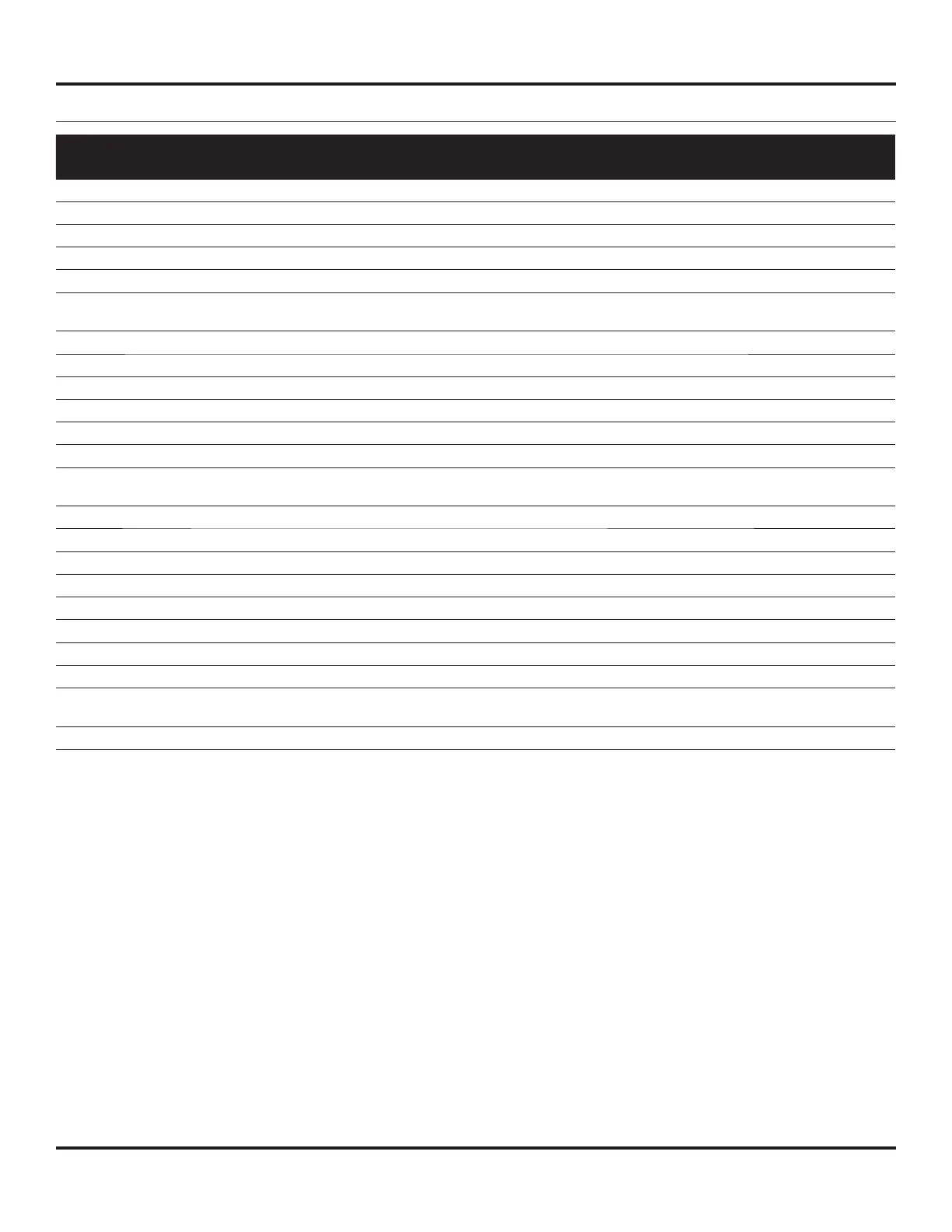

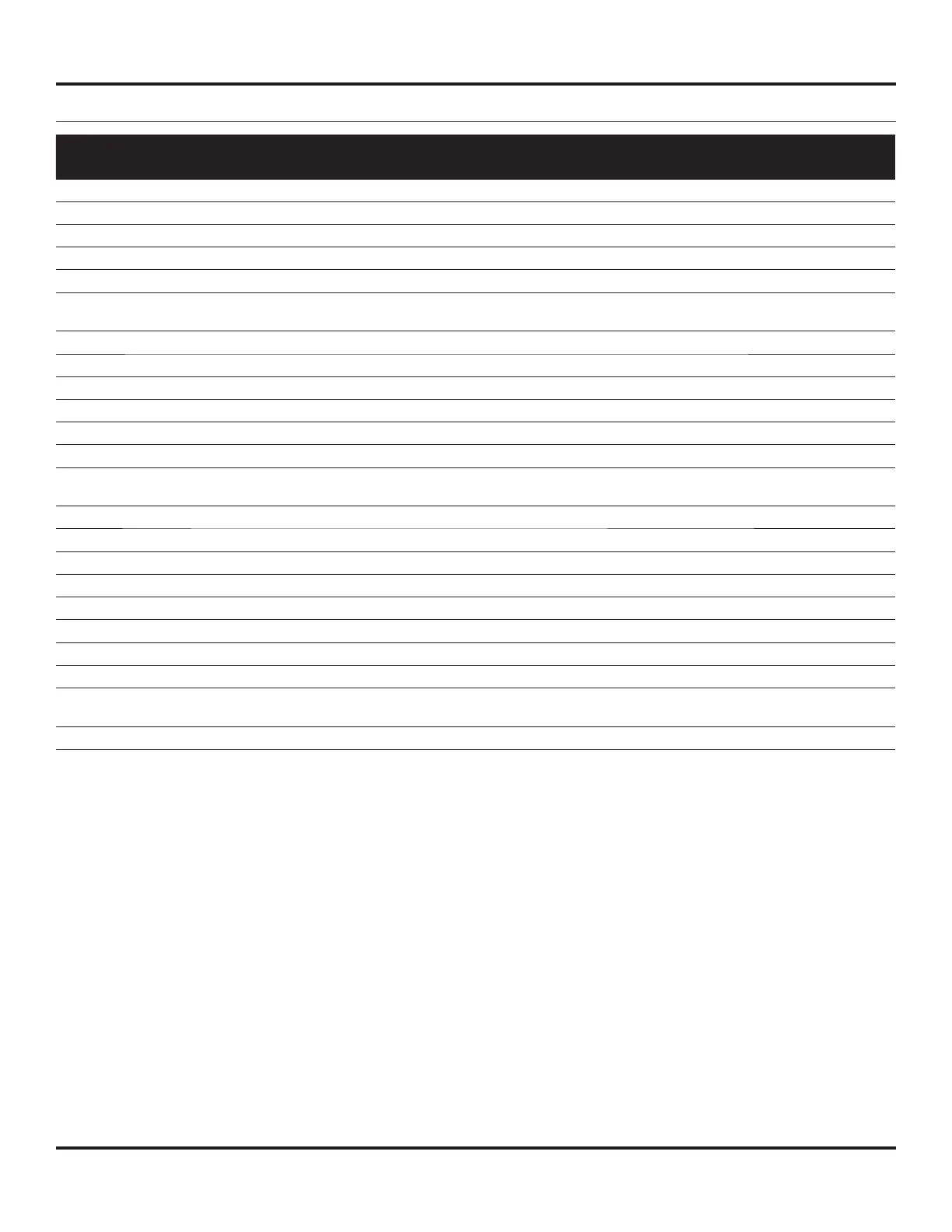

Scroll Enclosure Air Compressors

Operating Hours

Item Action Needed 500 2500 5000 10,000 20,000 Remarks

Intake Filter Clean, replace

●▲

Every 500 hours or less

Ventilation Screen Clean

●

Every 500 hours or less

Air End/ Blower Fan Clean

●

Every 5000 hours or less

Fan Duct Clean

●

Every 5000 hours or less

Compressor Fins Clean

●

Every 5000 hours or less

Compressor Grease

▲▲

(pump)

Use genuine Powerex grease

(Every 5000 hours for high pressure models)

Tip Seal Replace

▲

(Every 5000 hours for high pressure models)

Dust Seal Inspect, replace

▲

(Every 5000 hours for high pressure models)

V-belt Inspect, replace *

●▲

* Readjust

Temperature Sensor

●

Confi rm operation

Pressure Sensor Confi rm operation

●

Magnetic Starter Inspect

●

Replace if contact points deteriorated

Check valve Inspect

●▲

Confi rm operation by watching pump shut

off

Safety Valve Confi rm operation Every 500 hours or less

Ventilation Fan Inspect

●

Replace if malfunctions

Pulley Inspect groove

●

Repair if abnormal wear is detected

Motor Inspect

●●

Replace if abnormal noise is detected

Intake hose Replace

▲

Air Hose Inspect, replace

●▲

After Cooler Clean outside

●

Every 5000 hours or less

O-ring Replace

▲

Operating Panel

Inspect monitor

display

Daily

Piping Inspect for leakage

●

● Inspect

▲ Replace

NOTES:

1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operation conditions. If the circumstances and load condition are adverse,

shorten the cycle time and perform maintenance accordingly.

3. *Marked “Readjust” means the tension of the V-belt should be adjusted during the initial stage and inspected every 2,500

hours afterwards.

Chart 18

Maintenance Schedule

Loading...

Loading...