MODEL P2201 CAT. NO.52006/Deluxe Kit 52007/Blister Pack

6 P2201

followed by the fastener.

17.Never attempt to override the safety features of this tool.

HANDLING THE TOOL AND POWDER LOADS

1. Never leave a loaded tool unattended. Once the tool is

loaded, make the fastening immediately or unload the tool.

2. Always unload the tool before work breaks, changing parts,

cleaning or servicing, and when storing.

3. To prevent accidental discharge of loads, never carry the powder

loads in the same container as the fasteners or other hard objects.

4. Always store the powder loads in the containers provided or in

an enclosure provided for them. Never intermix the various power

levels. Keep them segregated in clearly identified containers.

5. Powder loads should never be used in firearms. They are normally

more powerful that the cartridges supplied with the firearms.

6. Powder actuated tools and powder loads should always be stored

under lock and key. Tools must be unloaded when not in use.

TOOL MALFUNCTION

1. In the event that a load fails to discharge after the trigger is

pulled, the tool must be kept depressed against the work surface

for a minimum of 30 (thirty) seconds in case of a delayed load

discharge. Then carefully remove the entire load strip. and

dispose of it in a can of water or other nonflammable liquid.

Never attempt to force or pry a load out of a tool chamber.

2. Never discard unfired powder loads into a trash container.

3. Do not attempt to unload or disassemble a jammed, stuck or

broken tool as improper handling may cause it to discharge and

strike operator and/or bystander. A jammed tool must be pointed

in a safe direction at all times. Tag the tool and lock it up. Call

your Powers Fasteners representative for proper assistance.

Tool Operation

CAUTION:

— Be sure to read and understand all of

thesafety precautions and training in this manual before

attempting to operate the tool. (Check to be sure the tool is

not loaded, the piston moves freely within the

barrel, and no foreign objects or fasteners are in

the barrel.) Perform the daily function test

before using the tool.

OPERATION

1. Always point the tool in a safe direction

away from bystanders and the operator. Slide the barrel

forward. This can be done by snapping your wrist. The barrel

should be pulled fully forward to reset the

piston for the next fastening. Loss of

power may result from an im properly

positioned piston.

2. Always load the fastener before

inserting powder load to prevent injury to the operator or

bystanders in the event of an accidental discharge. Place the

fastener, point out, into the end of the

nose piece until the fluted tip fits inside.

Do not use excessive force when inserting

the fastener. If excessive force is required,

stop and determine why the fastener can

not be inserted. Correct the problem

before proceeding.

NOTE: Do not use fasteners longer than 3" as listed in the

fastener selection section of this manual.

3. Make sure the breech is clear. Insert the powder load

starting with the lowest power level. If this Load does not fully

set the fastener, try the next higher power level until the proper

level is found.

NOTE: Over driving or over powering a

fastener can cause a safety hazard.

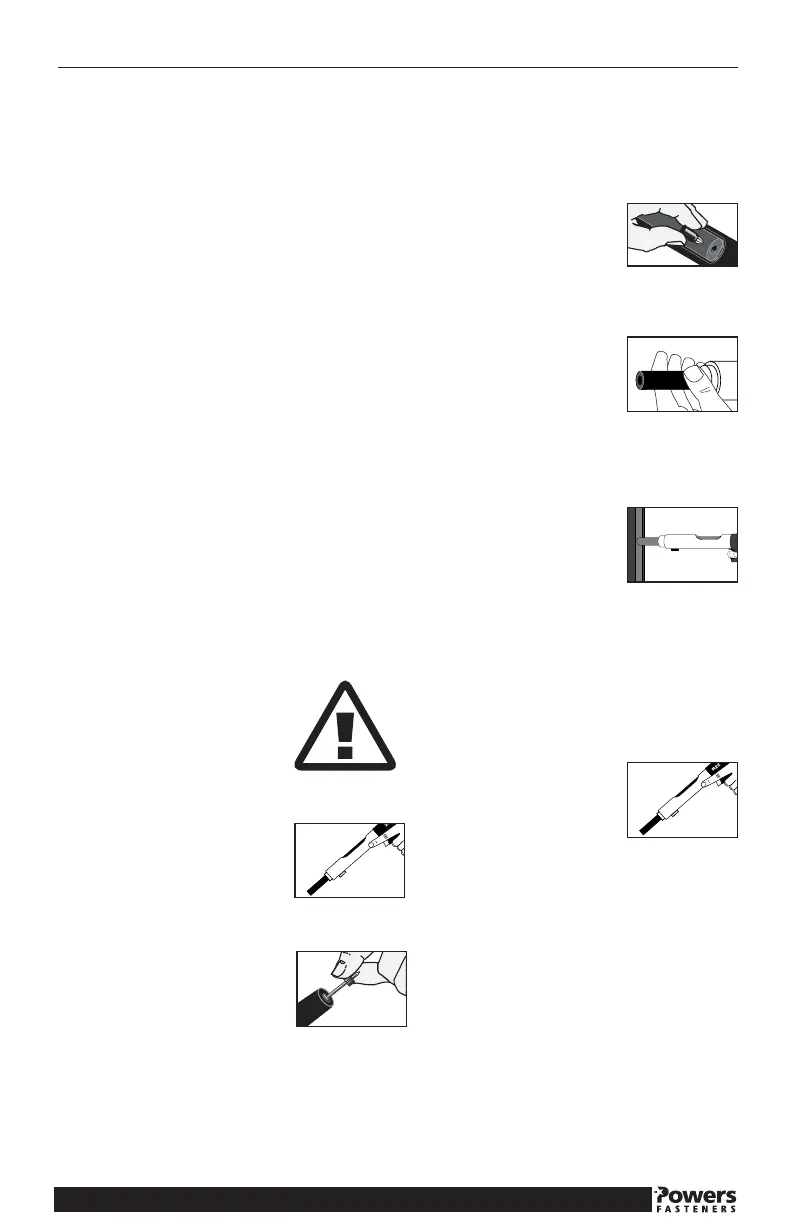

4. Pull the barrel all the way back to

close the tool. Do not attempt to close

the tool by exerting force on the front of the nose piece. Never

place your fingers or hands over muzzle bushing. The safe

position for hands and fingers are as shown in the diagram.

Hands must never be placed in front of

the tool muzzle or nose piece. In the

event of an accidental discharge, the

piston and/or fastener can pass

through the operators hand.

5. Once the tool is in the closed position, place it against the

work surface. Hold the tool firmly with two hands and

completely depress the barrel. Then squeeze the trigger. Always

hold the tool perpendicular to the work surface. Hold the tool

firmly against the work surface to avoid excessive recoil. Never

depress the tool against anything

except the work surface.

NOTE: In the event that the load does

not discharge after the trigger is pulled,

continue to hold the tool depressed

against the work surface for at least 30 (thirty) seconds in case

of a delayed load discharge. Then carefully remove the load

and dispose of in a can of water or other non flammable

liquid. Never attempt to force or pry a load out of a tool

chamber. Do not discard unfired loads into a trash container.

6. To prepare for the next fastening, point the tool in a safe

direction. Snap the barrel forward as described in step 1. This

action will eject the spent powder load and properly reset the

piston. Always insert a new fastener before loading powder

load in the chamber. Do not attempt to unload or disassemble

a jammed, stuck or broken tool as

improper handling may cause it to

discharge and strike operator and/or

bystander. A jammed tool must be

pointed in a safe direction at all times.

Tag the tool and lock it up. Call your Powers Fasteners

representative for proper assistance.

Loading...

Loading...