MODEL P2201 CAT. NO.52006/Deluxe Kit 52007/Blister Pack

8 P2201

Proper Maintenance and

Cleaning

MAKE SURE THE TOOL IS NOT LOADED. BE SURE

THE TOOL IS NOT HOT PRIOR TO ATTEMPTING

DISASSEMBLY OR CLEANING.

DAILY FUNCTION TEST

Check the functioning of the tool, without a powder load or

fastener in the tool, by pushing down against the work surface,

pulling the trigger, and releasing the tool from the work surface.

Function the unloaded tool several times and insure that the

breech parts and firing mechanism operate freely before

fastening with the tool.

Your Powers Fasteners Authorized representative should be

asked to assist the first time you disassemble and

clean your tool.

If you ever have any trouble reassembling the tool, or have

any doubt about worn parts, call your Powers Fasteners

Authorized Powder Distributor.

CLEANING

AIl parts should be cleaned with detergent oil and the wire

brushes supplied with your tool kit. Remove heavy dirt build-up

with the brush. After cleaning with oil, all parts should be wiped

thoroughly dry. Excess oil will tend to collect dirt and dust. Wear

eye protection when cleaning the tool.

The piston rod, barrel assembly, and receiver should all be

cleaned of excess dirt on a daily basis. Check the condition of

the piston for damage to the piston for wear and deformation.

To maintain this tool in good working condition, it is

necessary to disas semble and clean the entire tool if dirt is evident

in the breech face, or if the tool appears to lose power. All parts

should be cleaned with oil and wire brushes. Remove heavy dirt.

All parts should be wiped thoroughly dry after cleaning with oil.

General tool mainte nance should be performed at six month

intervals or more frequently as required by the frequency of tool use.

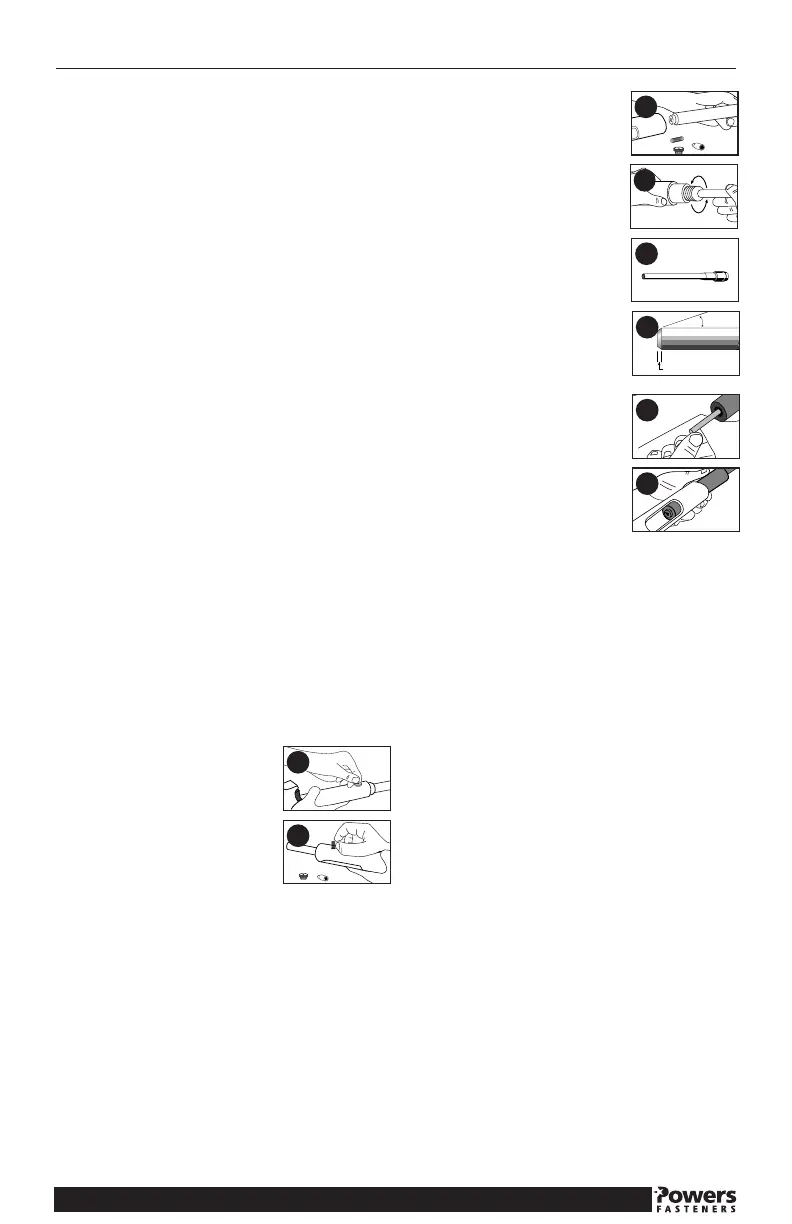

REPLACING OR REPAIRING THE PISTON

The piston is an expendable part and must be replaced

periodically. Typical signs of a worn out

piston are: breaking, bending or

mushrooming. Prior to servicing the tool

make sure there is no powder load in the

tool. Use caution and do not lose or

damage any tool parts.

1. Loosen the cap on the reset pin by

turning it counter clockwise. Remove the

reset pin cap.

2. Hold the barrel in place, then remove the reset pin spring and

reset pin.

3. Slide the barrel from the receiver by

pulling it forward. If excessive dirt is built up

inside the receiver, clean it with a wire brush.

4. Unthread the nose piece from the barrel

by turning it counter clockwise. Pull the

piston forward out of the barrel.

NOTE: If a vise clamp is used to hold the

barrel, protect the bar rel from damage.

5. Clean the piston using a wire brush.

Inspect it for worn or damaged piston ring,

chipped end, or bending. Apply lubricant to the

piston shank to minimize piston sticking from

an overdrive con dition. Wipe the piston dry.

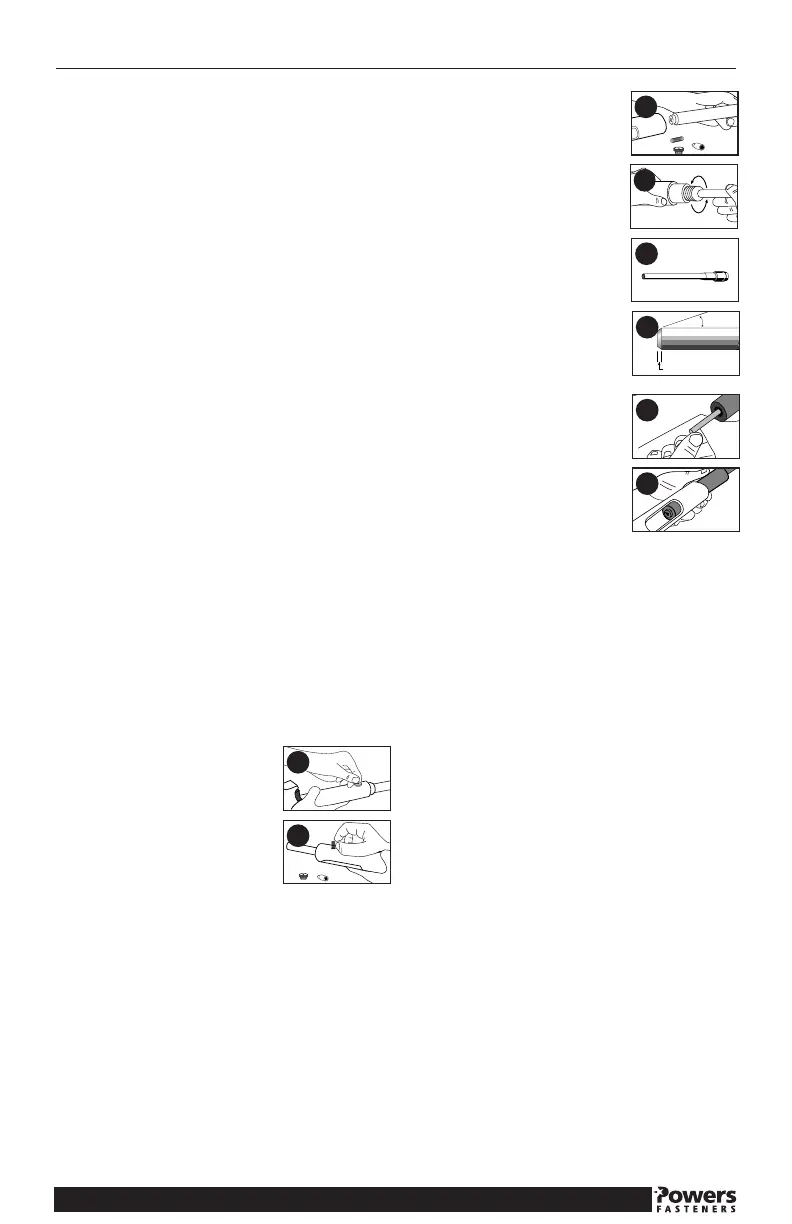

6. If a piston tip is damaged, it can be

shortened a maximum of 0.20 inches. The

tip of the piston

should be grooved flat and at 90 degrees to

the shank of the piston. The cham fer of the

piston must also be reground as

shown. Piston grinding should be performed

by qualified per sonnel using the proper

equipment.

REASSEMBLY:

7. Press the piston into the barrel. Thread

the nose piece into the barrel and tighten it

clockwise until finger tight. Be sure the nose

piece is fully seated.

8. Align the slot in the barrel with the reset pin opening in the

bottom of the receiver. Insert the barrel into the receiver. Insert

the reset pin, and reset pin spring. Tighten the reset pin cap

clockwise until it is finger tight and fully seated.

Upon reassembly of the tool perform the following test.

Depress the tool against a flat, hard surface and pull the trigger.

The barrel assembly should slide smoothly inside the tool receiver.

The firing pin should release after the trigger has been pulled.

CAUTION: THIS TEST SHOULD BE PERFORMED

WITHOUT A PIN OR POWDER LOAD IN THE TOOL.

1

2

3

4

5

6

7

8

Loading...

Loading...