Figure 5

The center

between the

two holes to be

drilled

The center of

the hole to be

drilled

The center of

the hole to be

drilled

NOTE: When drilling two holes, align the central line on the jig

with the mark.

NOTE: When drilling single holes, align one of the two outside

lines with the center of the hole being drilled.

2. Start to drill the hole, drill at a slow speed until the stop

collar touches the edge of the jig.

Figure 6

Drilling Holes into Assembled Material

The POWERTEC Pocket Hole Jig can also be used to repair or

strengthen previously assembled case goods or drawers.

1. Reference the Drilling After Assembly chart for the

appropriate drill length for the material thickness

2. Measure from the bottom of the stop collar to the first step of

the drill bit and tighten the stop collar.

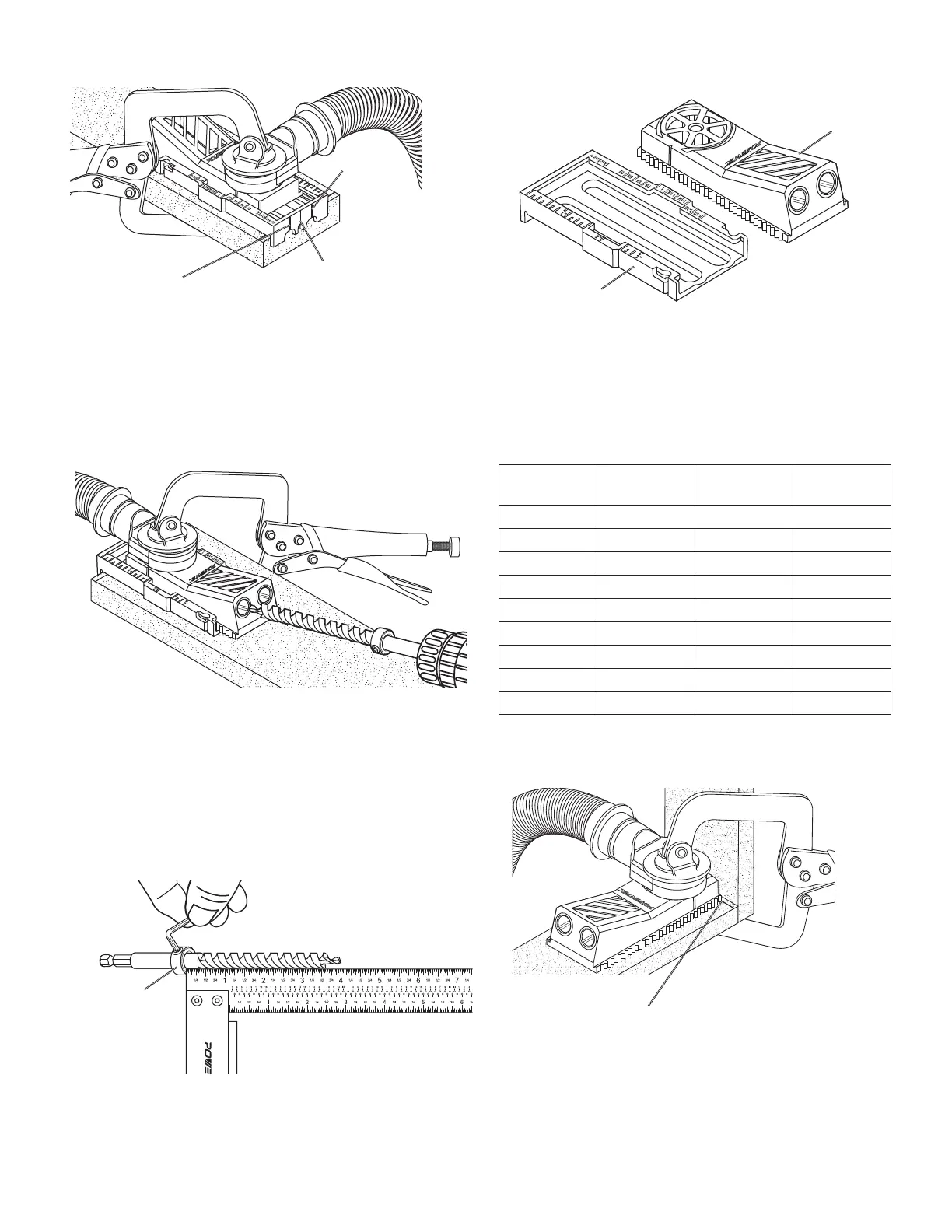

Figure 7

Stop Collar

3. Remove the pocket hole jig body from the pocket hole jig

slide bracket.

Figure 8

Pocket Hole Jig Slide Bracket

Pocket Hole Jig Body

4. Scribe a line on the assembled material. Reference

the Drilling After Assembly chart for distant from the

edge measurement

5. Align the edge of the pocket hole jig to the scribed line

and clamp firmly in place with the appropriate clamp for

the application.

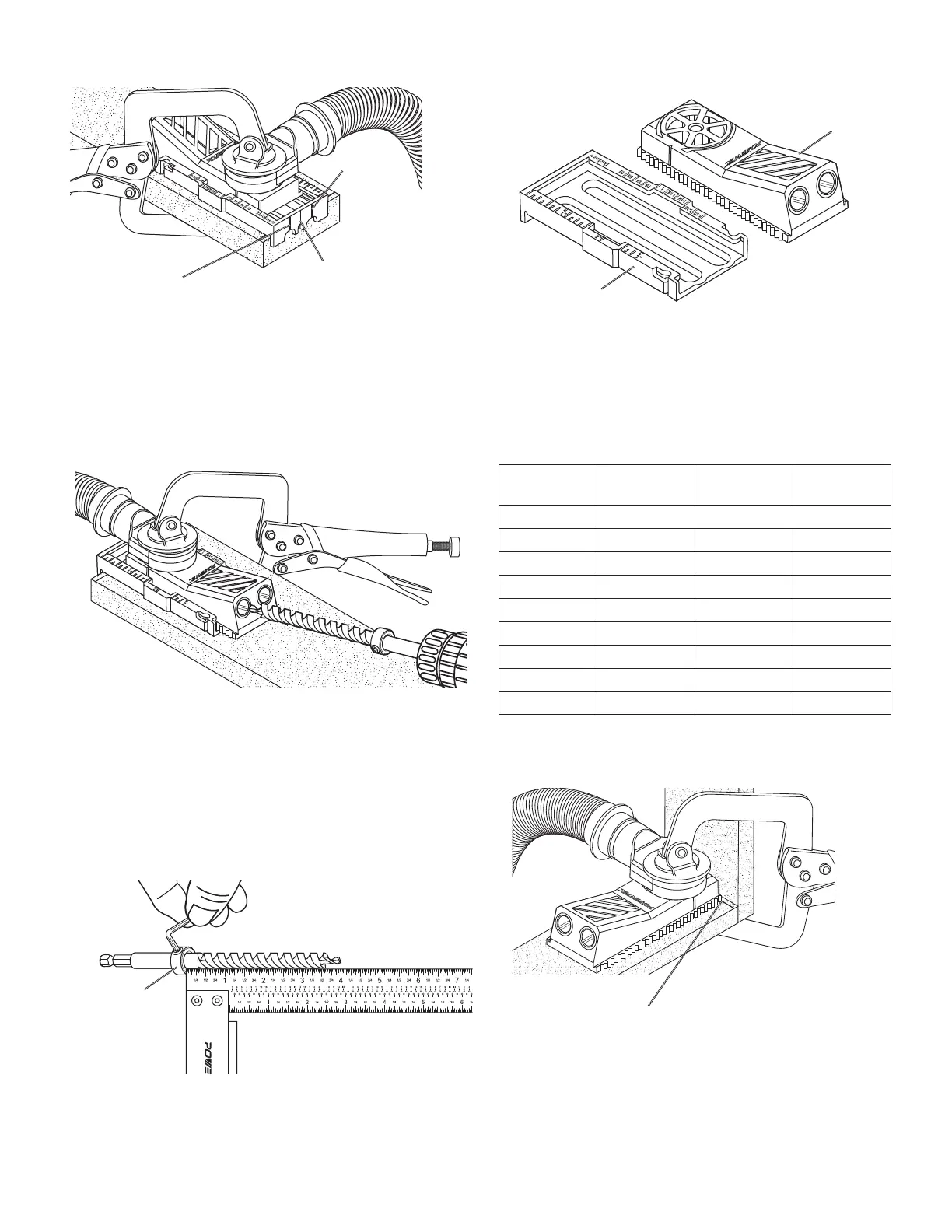

Drilling After Assembly

Material

Thickness

Distance

from Edge

Drill

Length

Screw

Length

1/2"

NOT RECOMMENDED

5/8" Snap to edge 3‑1/2" 1"

3/4" 1/8" 3‑1/2" 1‑1/4"

7/8" 3/8" 3‑3/4" 1‑1/2"

1" 5/8" 3‑3/4" 1‑1/2"

1‑1/8" 7/8" 4 1‑1/2"

1‑1/4" 1‑1/16" 4 2"

1‑3/8" 1‑5/16" 4 2"

1‑1/2" 1‑9/16" 4 2‑1/2"

Figure 9

Align to scribed mark

6. Start to drill the hole, drill at a slow speed until the stop

collar touches the edge of the jig.

Loading...

Loading...