2

Cold fresh air

from outside

100-150 mm

from the ceiling

Removal of warm exhaust air

from the premises

Inflow & exhaust are

operating simultaneously

with no air flows mixing

Copper

heat exchanger

Preheated fresh air

from outside

Unit slope

3-5 degrees

Removal of exhaust air

from the premises

INTENDED USE

PRINCIPLE OF WORK

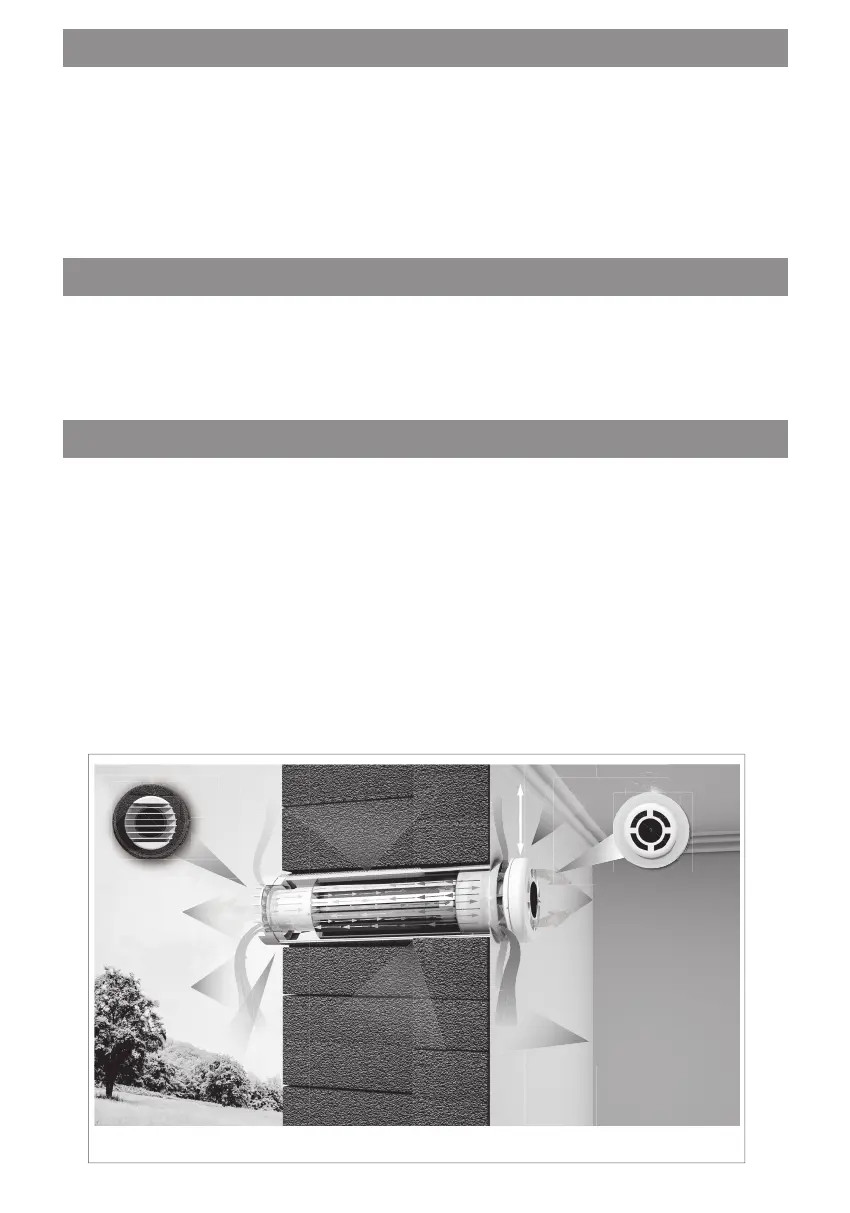

The basis of the technical solution for recuperation ventilation is the countercurrent, with a

continuous thermal cycle, a copper heat exchanger, which makes it possible to form two

different-directed airflows in the volume of one cylinder (Fig. 1).

Warm exhaust air that is removed from the room, passing through a copper heat exchanger

transmits its warmth to the counter stream of fresh air from the outside.

The system allows recover heat, which contributes to increasing the overall recuperation

rate and allows maintain the optimum humidity mode in the room. Taking into account that

air streams are separated and regulated at levels “inflow” – “exhaust”», there is no mixing of

different-directional air flows.

High velocity of the flow with sufficient heat transfer efficiency ensures removal of up to

90% moisture in a dispersed state, preventing its condensation and freezing of the heat

exchanger at low ambient temperatures.

DESCRIPTION OF THE DEVICE

Ventilation units “PRANA-150”, “PRANA-200C”, “PRANA-200G” are intended for creation and

maintenance of healthy microclimate in premises.

These systems are recommended for use in residential and public facilities (apartments,

houses, office premises, educational establishments, kindergartens, etc.).

PRANA-150 and PRANA-200G belong to the category of innovative and reliable ducts

aimed at creating and maintaining a healthy microclimate in premises of various functional

purposes.

High energy efficiency and significant air exchange capabilities make it possible to apply

these ventilation units for organizing domestic ventilation.

Technologically, the system is a monoblock with high-efficiency counter-current copper

recuperator ready to use in accordance with the design and assembly tasks and conditions.

Fig.1. The principle of work of recuperator PRANA-150, PRANA-200C, PRANA-200G

Loading...

Loading...