12PM-1440BV v3 2020-10 Copyright © 2020 Quality Machine Tools, LLC

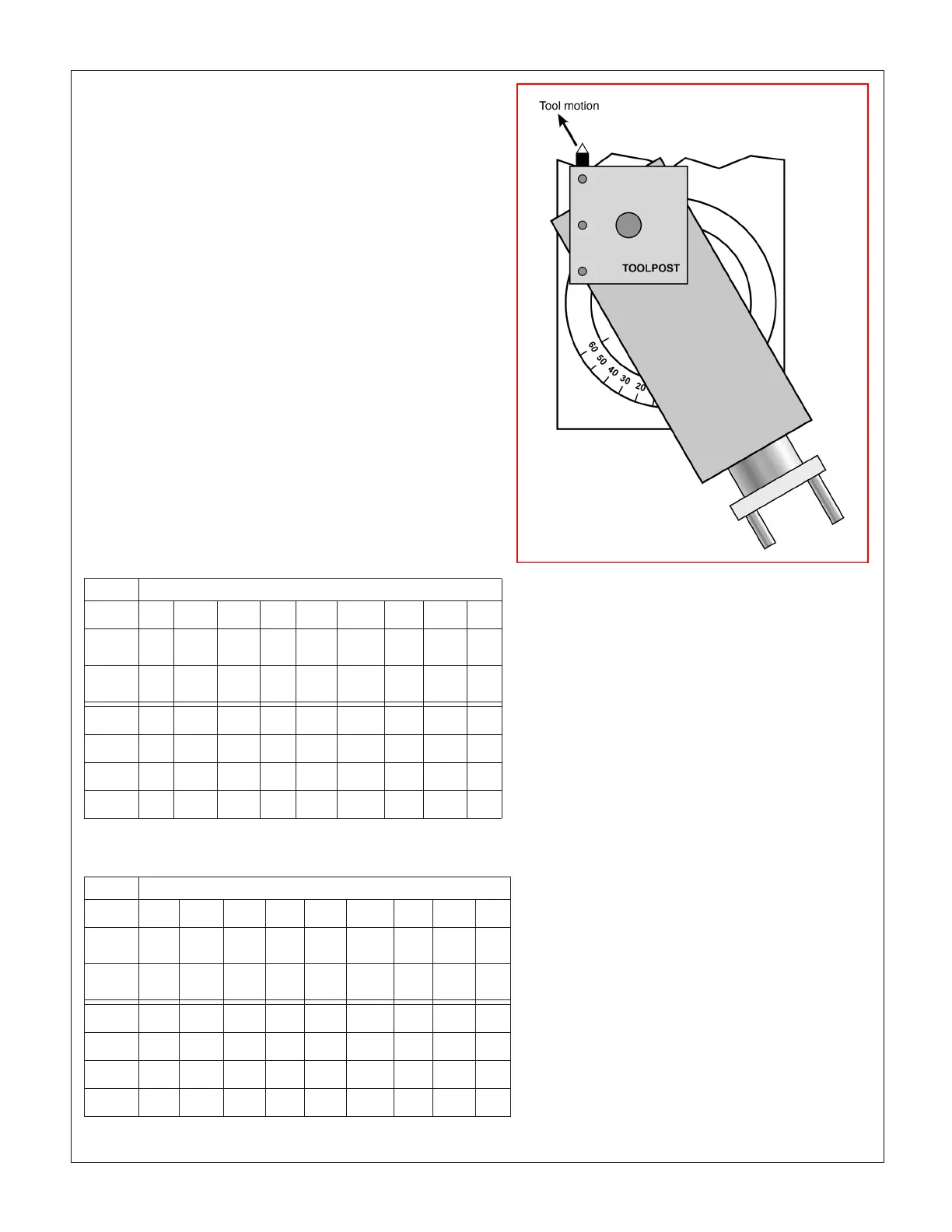

Gear shifters

R-1 U-1 U-1 U-1 U-1 U-1 T-1 U-1 U-3

er

gear

60 60 60 60 40 40 30 40 60

er

gear

60 54 57 60 44 46 60 52 63

A-D 4 4-1/2 - 5 5-1/2 - 6 6-1/2 7

B-D 8 9 9-1/2 10 11 11-1/2 12 13 14

A-C 16 18 19 20 22 23 24 26 28

B-C 32 36 38 40 44 46 48 52 56

Figure 3-9 Threads per Inch (TPI)

Gear swapping

Any change to the drive train typically calls for one or both

of the upper and lower gears to be exchanged for a larger or

smaller gear. This will require the transposing gear pair to be

repositioned. The procedure for this is:

1. Use a 18 mm wrench to remove the hex nuts from the up-

per and lower gear shafts.

2. Remove the gears, washers, keys and bushing (lower gear

only).

3. While holding the gear support casting (quadrant) with one

hand, use a 16 mm wrench to loosen its anchor nut. Allow

the casting to swing downward.

4. Loosen the 16 mm hex nut securing the transposing gears

to the support casting.

5. Install the lower gear (for TPI threads the 120T gear is out-

side, for metric threads, inside).

6. Bring the transposing gears into mesh with the lower gear,

trapping a scrap of bond paper (letter stock) between the

two to hold them at the correct separation.

7. Tighten the transposing gears in position, then remove the

paper. Check for working clearance between the gears.

8. Install the upper gear.

9. Swing the gear support casting upward to mesh the 127T

gear with the upper gear, again using a paper scrap for

separation.

10. Tighten the gear support casting.

11. Lubricate the gears.

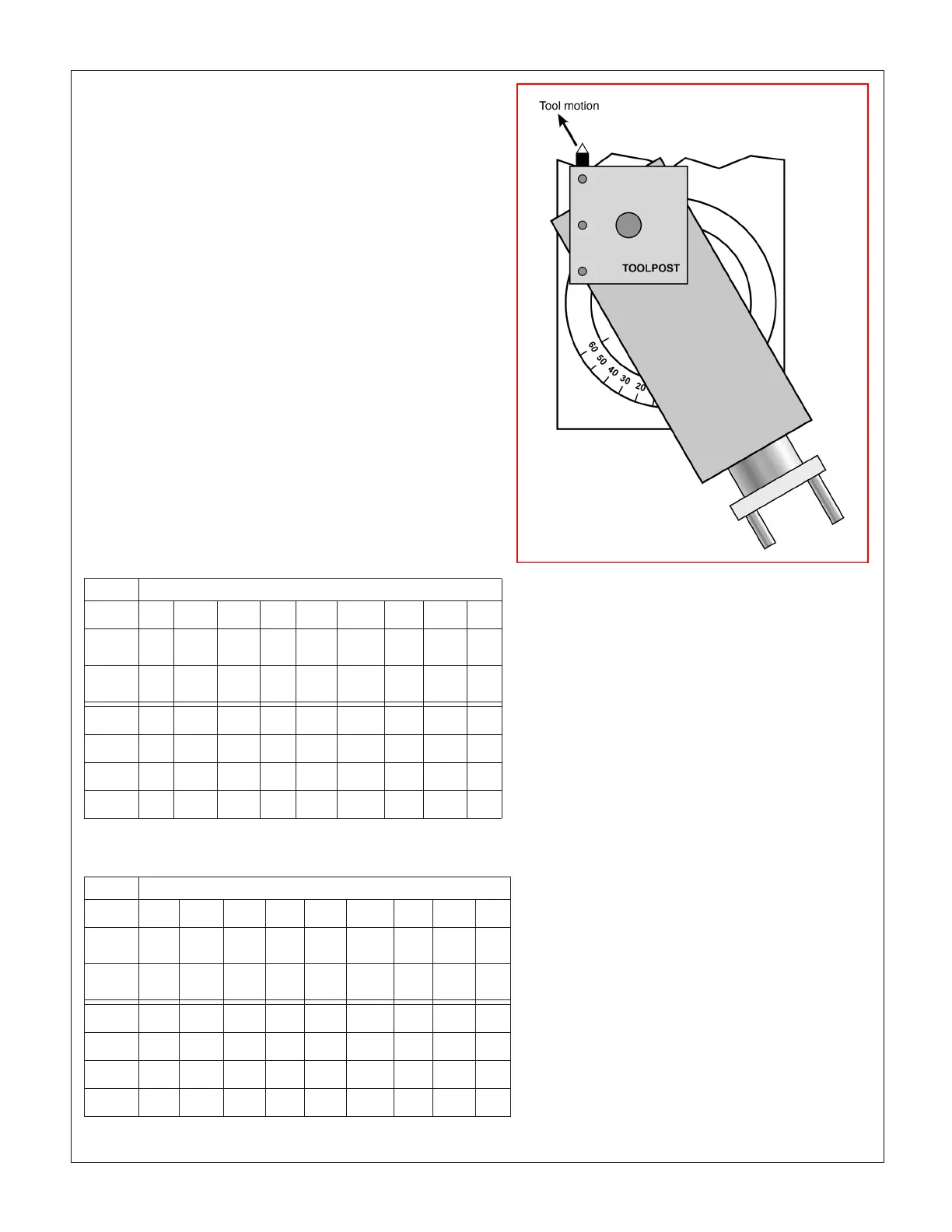

Gear shifters

R-4 U-4 S-3 T-4 U-1 R-3 T-1 U-3 U-1

er

gear

56 60 60 30 60 60 30 60 42

er

gear

60 60 60 60 60 60 60 60 63

A-D 7.0 6.0 - 5.0 - 4.5 4.0 - -

B-D 3.5 3.0 - 2.5 - 2.25 2.0 1.8 1.6

A-C 1.75 1.5 1.4 1.25 1.2 - 1.0 0.9 0.8

B-C - 0.75 0.7 - 0.6 - 0.5 0.45 0.4

Figure 3-10 Metric thread pitches (mm)

COMPOUND SETUP FOR THREAD CUTTING

Thread cutting on the lathe is unlike most other turning

operations, for two reasons: 1. The cutting tool must be

precisely ground with an included angle of 60 degrees

for most American and metric threads, and; 2. It is pref-

erable to feed the tool into the workpiece at an angle

so it cuts mostly on the left ank of the thread, Figure

3-11. The correct angle relative to the cross slide (zero

degrees) is debatable — should it be 29, 29-1/2 or 30

degrees? Many machinists prefer 29 degrees because

it holds the cutting tool marginally clear of the right ank

of the thread, close enough for cleanup of the ank while

at the same time avoiding appreciable rubbing.

CUTTING PROCEDURE FOR TPI THREADS

This procedure assumes that a single point thread cut-

ting tool will be used, and that the threading dial assem-

bly, Figure 3-13, has been pivoted forward to engage its

worm wheel with the leadscrew.

The threading dial cannot used for metric threads!

The split-nut on the apron must be left engaged

throughout the entire process.

For metric and UNC/UNF threads the tool is ground to

60

o

(included angle). It is installed so that its anks are

exactly 30

o

either side of the cross axis, ideally with the

compound oset as Figure 3-11. Single-point threads

are cut in 10 or more successive passes, each shaving

a little more material o the workpiece.

Figure 3-11 Setting up the compound for 30

o

infeed

Loading...

Loading...