11PM-1440BV v3 2020-10 Copyright © 2020 Quality Machine Tools, LLC

FEEDSHAFT CLUTCH

The clutch shown in Figure 3-7 disengages the power feed if

the saddle or cross slide hits an obstruction when power feed-

ing, thus minimizing the potential for damage. This could be

the result of either an accidental event, or deliberately stopping

the saddle at a precise location set by the saddle stop, Figure

3-6.

The clutch comprises a pair of spring loaded steel balls bear-

ing on a detent disc driven by the saddle feed gearbox. Spring

pressure is adjusted by two set screws on either side of the

feed shaft, arrowed in Figure 3-7. Setting the spring pressure

is a process of aiming for the best compromise between too

high — damaging feed pressure — and too low, stopping pre-

maturely.

Setting the clutch to work reliably with the micrometer carriage

stop is a good example of such a compromise: start with low

spring force, then work up in small increments until the car-

riage stops in the same location (say ± 0.002”, assuming a

constant depth of cut and feed rate).

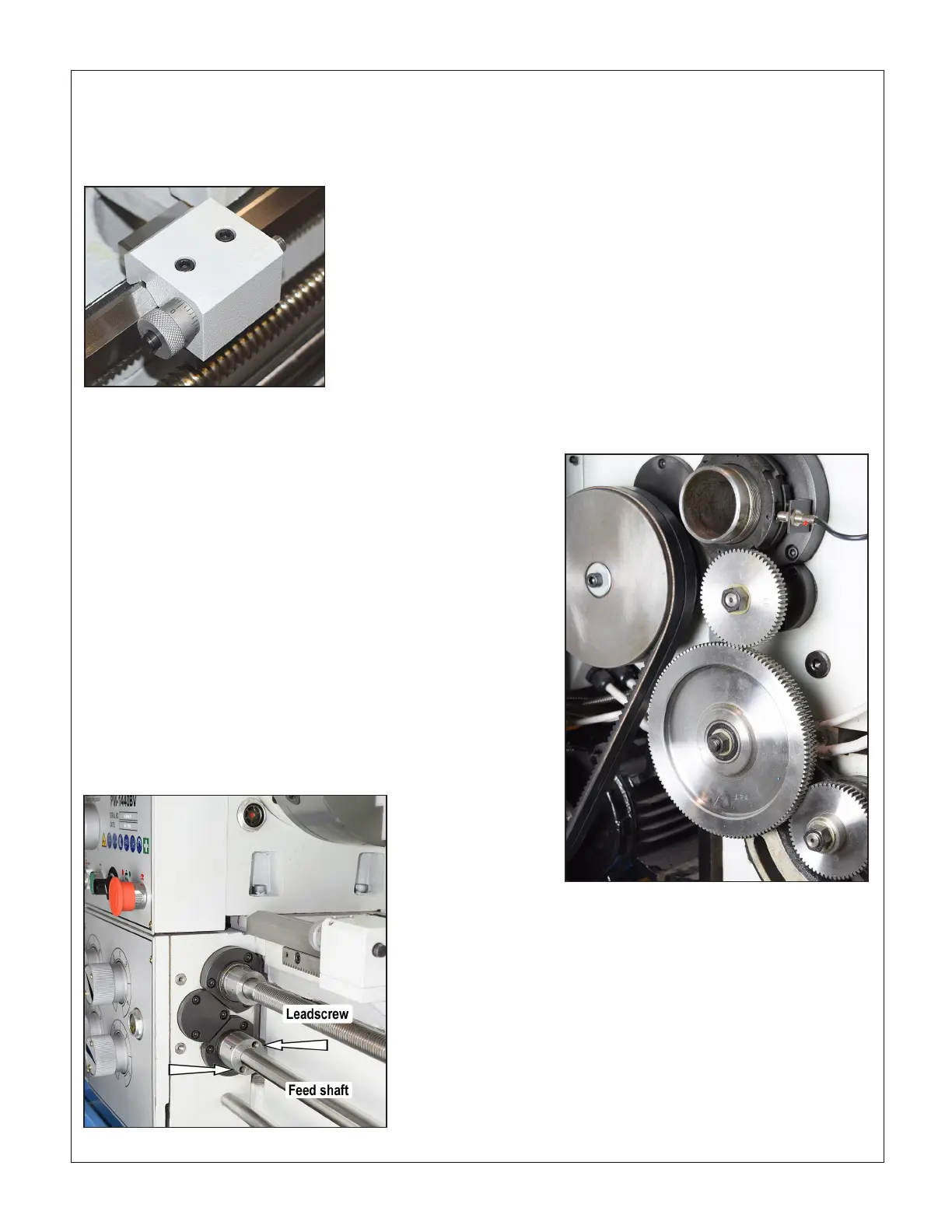

SADDLE STOP

The stop assembly, Figure 3-6, has a micrometer-style collar

graduated in 0.001 in. divisions. It can be clamped at any point

along the lathe bed (two M6 socket head screws on the under-

side secure the clamp plate to the block).

Figure 3-6 Saddle stop (representative)

Figure 3-7 Feedshaft clutch

THREAD CUTTING

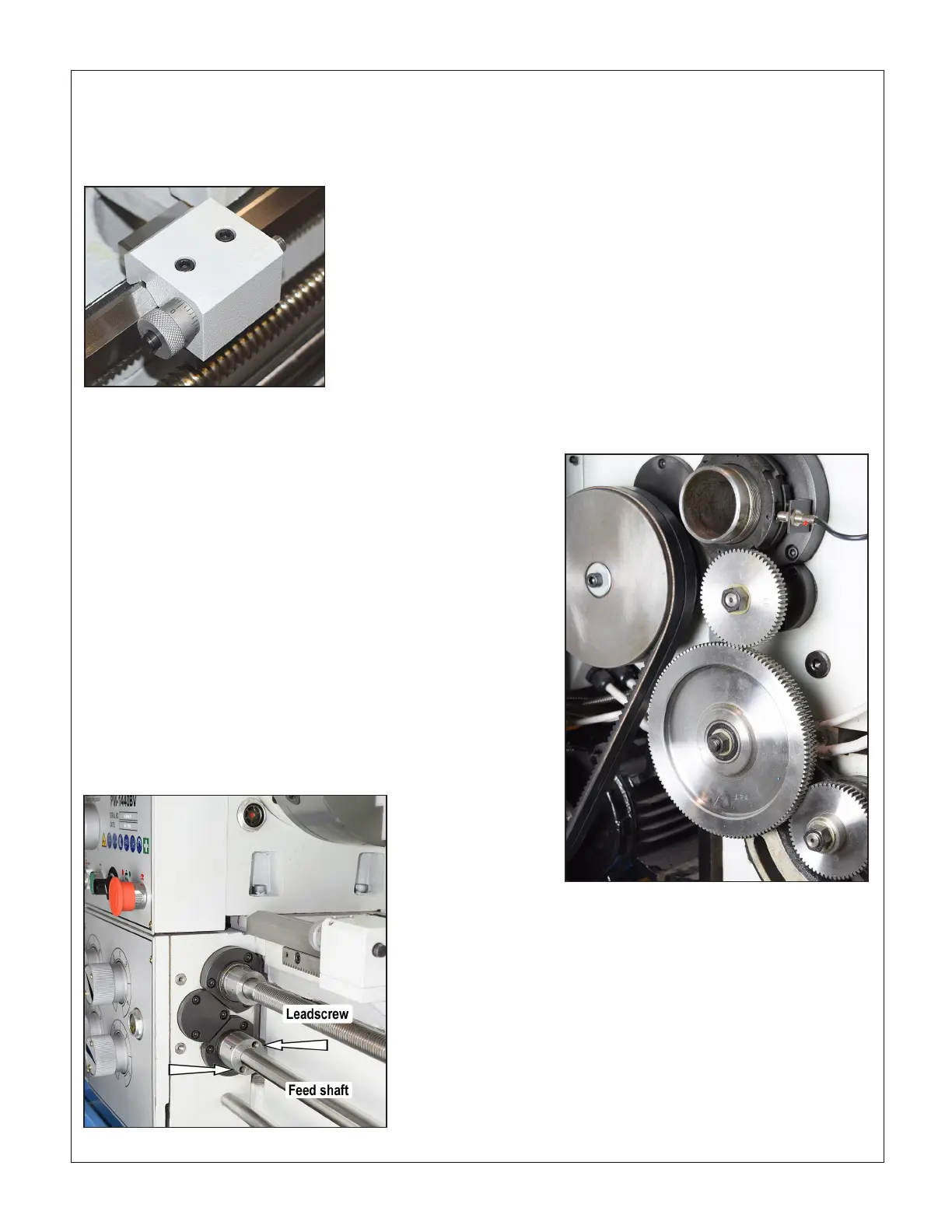

External change gears

The large gears in Figures 3-3 and 3-8 are transposing gears,

120T and 127T. They allow a standard-thread leadscrew, in

this case 8 TPI, to cut metric threads. The transposing gears

are cut from a single steel blank.

KEY FACTS TO REMEMBER ...

TPI threads

See Figure 3-3. For inch thread cutting, the 120T smaller gear

is simply an idler, transferring the drive from the upper change

gear to the lower change gear.

Metric threads

The upper change gear engages the 127T gear, Figure 3-8.

The smaller of the transposing gears, 120T, drives the lower

change gear.

For metric threads the split-nut on the apron must be left

engaged throughout the entire process.

Figure 3-8 External gear setup for metric threads

The lower change gear is installed hub outward.

METRIC vs. U.S. THREAD SETUPS

The 127T/120T transposing gear is installed 127T to the out-

side for metric threads, 120T out for U.S. threads. This calls

for reversal of the gear’s ball bearing assembly — two ball

bearings on a shouldered bushing. The bushing has to be

tapped clear of the ball bearings, then re-installed the other

way around.

A time-saving suggestion: Remove the shouldered bushing

and part-o the larger diameter portion. Re-install the smaller

diameter in the ball bearings. For the removed portion substi-

tute a separate plain collar. This will allow the transposing gear

to be installed either way with no additional eort.

Loading...

Loading...