11

PM 25MV v9 2021-12 Copyright © 2021 Quality Machine Tools, LLC

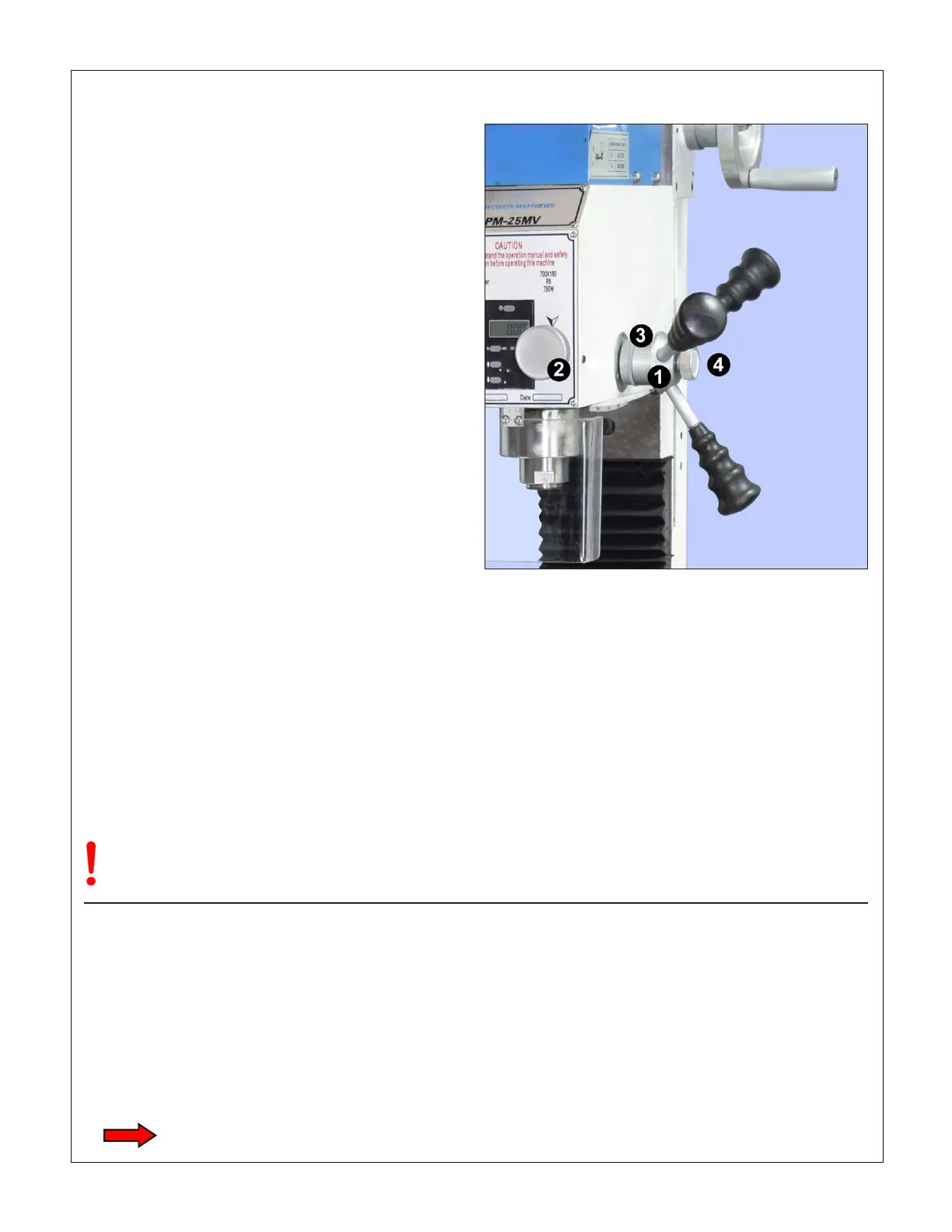

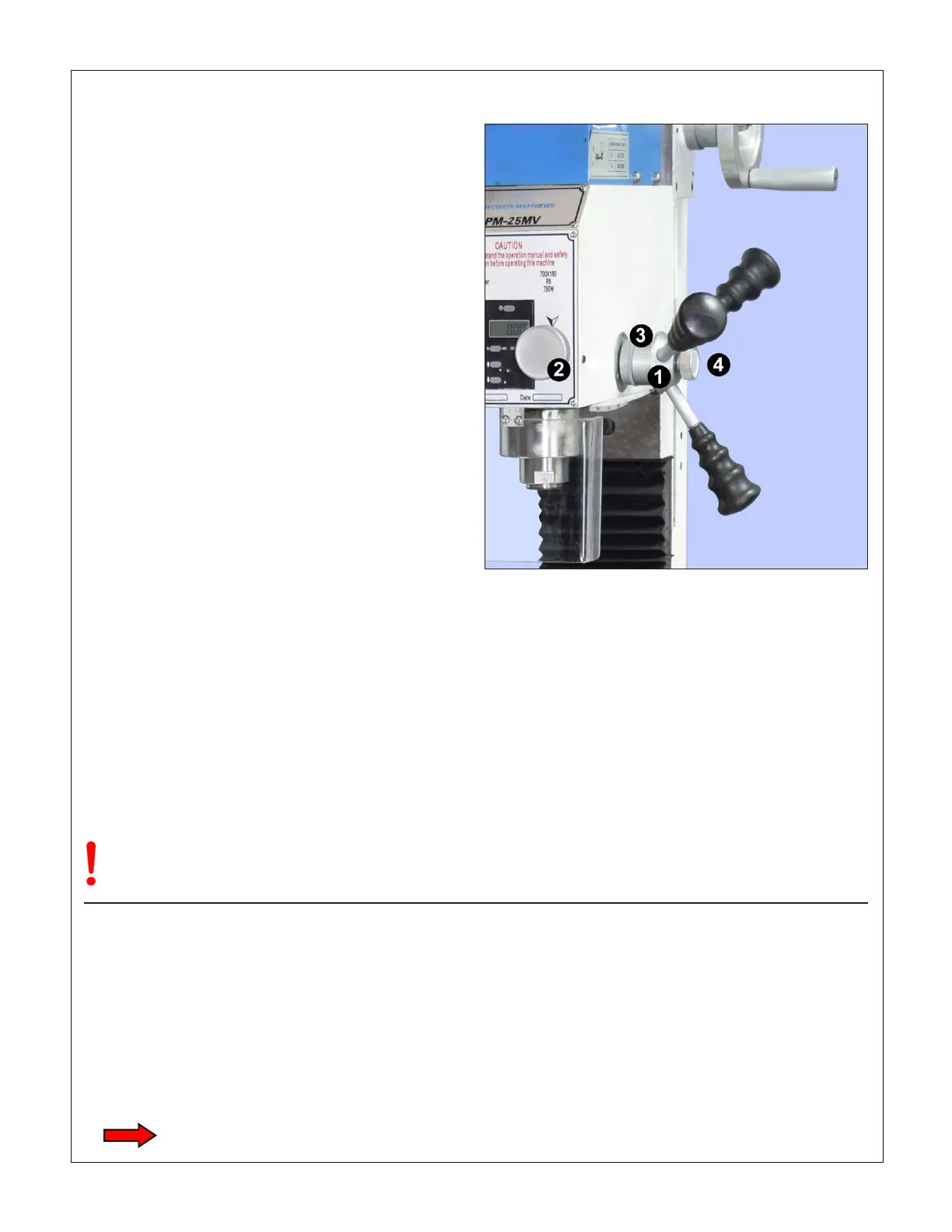

QUILL DOWNFEED

The quill is controlled in two dierent ways, coarse and

ne.

In the drilling mode, coarse feed, the mill operates like a

standard drill press with a 3-lever hub; lever action low-

ers or raises the quill in the usual way by rack and pin-

ion. Return action is assisted by a compression spring

within the quill and spindle assembly.

For milling operations the lever hub is not rotated by le-

ver action. Instead it is locked to a worm wheel, which

is turned by the ne control knob. This allows the quill

to be driven precisely to any desired position. The ne

control knob, because it drives through a worm, cannot

be back-driven by return-spring action on the quill (in

other words, it stays where it’s put). For milling opera-

tions the quill should be locked by the lever on the left of

the headstock, Figure 3-1.

Coarse feed (Figure 3-7)

For drilling operations, loosen knob (4), allowing the le-

ver hub to rotate independently of sleeve (3).

Fine feed (Figure 3-7)

For milling operations calling for precise, repeatable

control of tool depth, tighten knob (4) to engage hub (1)

with the internal taper on sleeve (3). Tighten the Z-axis

locks, Figure 3-6.

Rotate the ne control knob (2) to raise or lower the quill.

Lower the quill by rotating the ne control knob clock-

wise, positioning it precisely either by counting divisions

on the graduated dial, or by reference to the digital read-

out (DRO), Figure 3-1. Use the locking lever left of the

headstock to hold the quill rmly in position.

Figure 3-7 Quill downfeed controls

The lever hub (1) is connected at all times to the quill pinion, which

engages a rack on the back side of the quill. The ne control knob

(2) drives sleeve (3) through a worm gear. If clamp knob (4) is

unscrewed, both (2) and (3) rotate freely, doing nothing to the quill.

Fine feed is engaged by tightening knob (4) to clamp (3) and (1)

together.

If you are counting downfeed divisions be

aware of backlash in the worm drive.

The quill DRO – which has no backlash issues – oers a

much less laborious way of setting tool height, but note

that the quill is spring-loaded. This calls for care when

releasing the quill locking lever. If the ne control knob

has been allowed to disengage (backed o counter

clockwise), the quill may jump up by 0.01” or more. To

avoid this, make sure the ne control has been turned

clockwise to apply downward pressure on the quill be-

fore the locking lever is released.

QUILL DRO

The quill DRO is in metric mode when switched on.

Press the mm/in button to display inches.

Replace the battery by removing the small molded cov-

er on the face of the DRO unit (align the dots). Check

the type number and voltage of the installed battery. Re-

place with an equivalent silver oxide cell available from

local retailers.

Switch o the DRO when not in use!

Loading...

Loading...