41

Packaged and Split Rooftop Ventilator

© 2021 Mitsubishi Electric US, Inc.

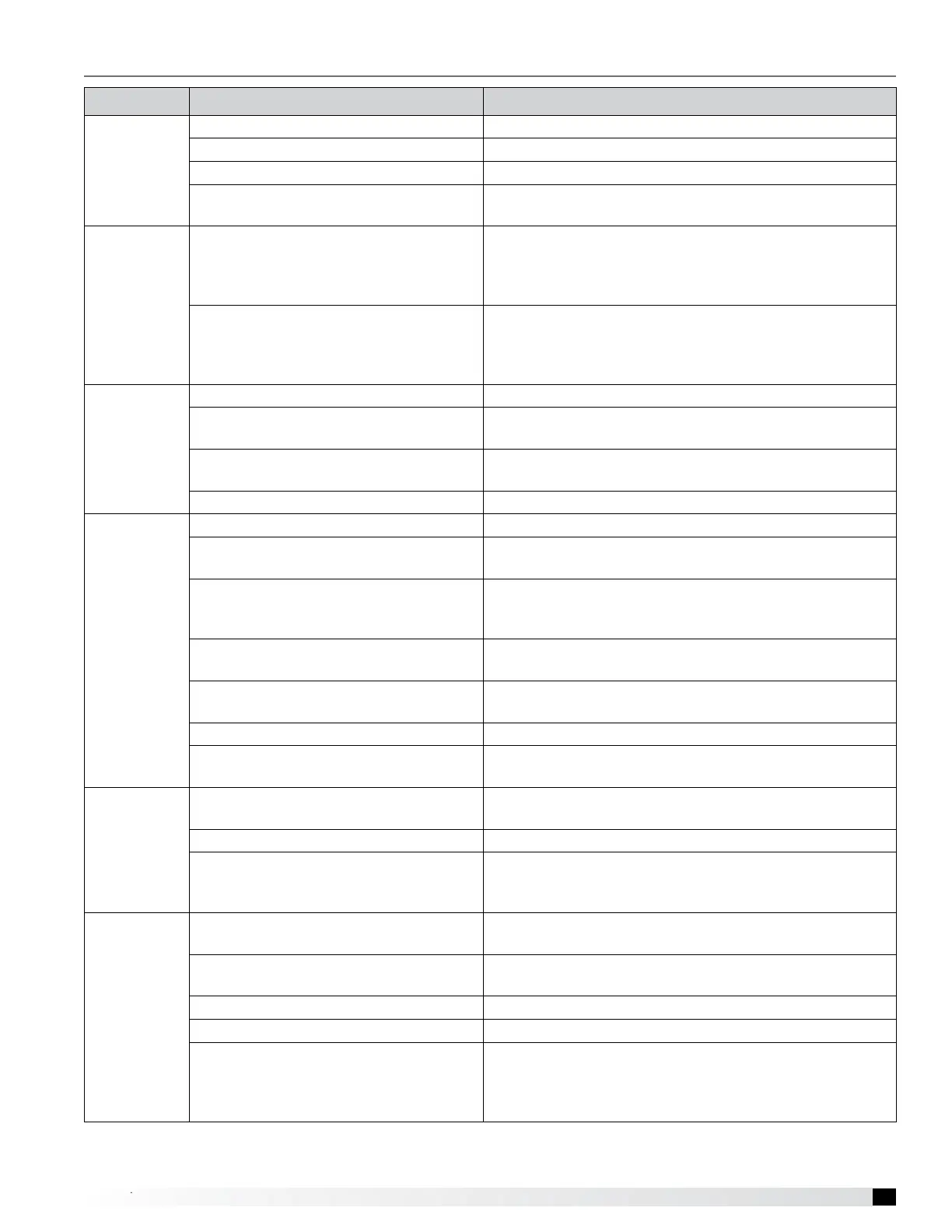

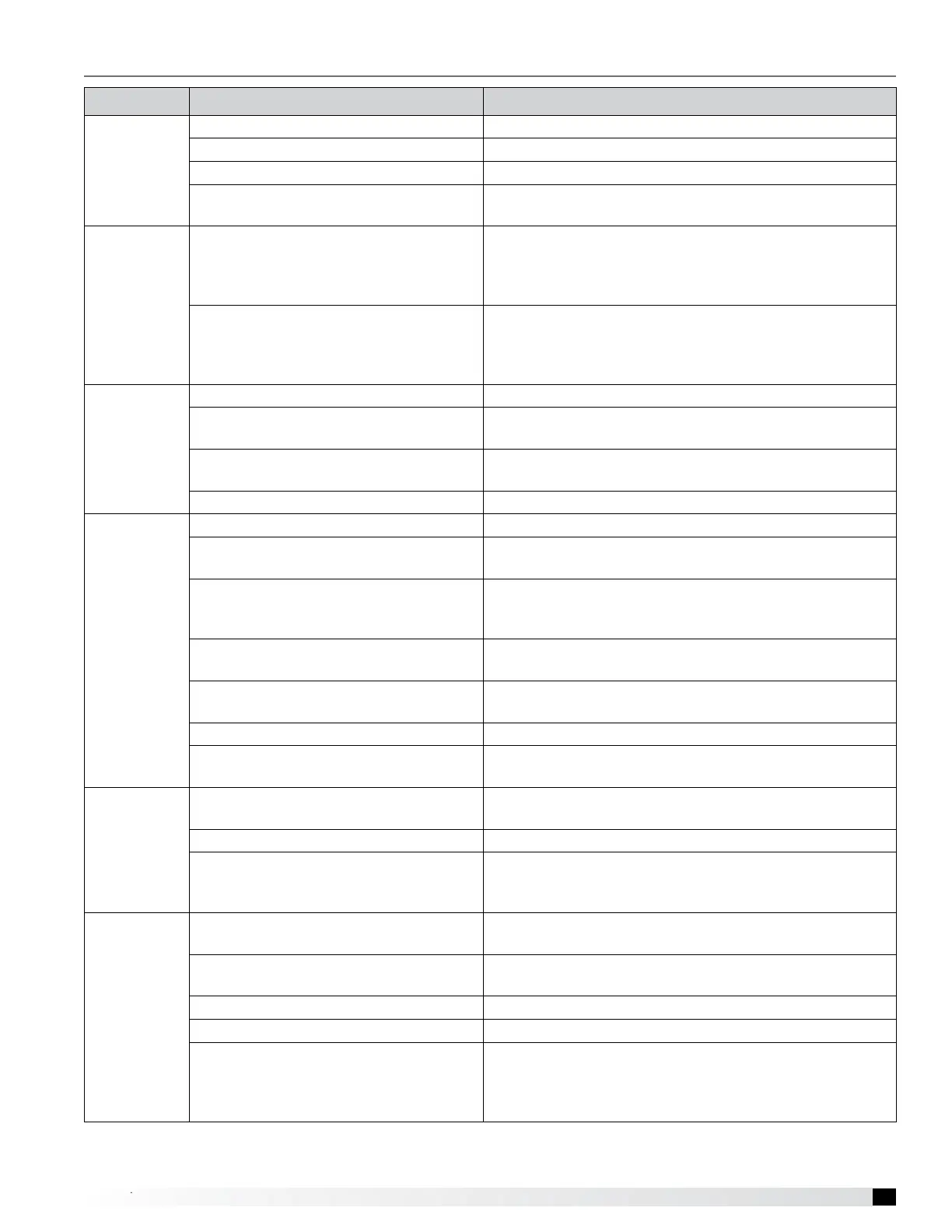

Troubleshooting – Unit

Symptom Possible Cause Corrective Action

Blower fails

to operate

Blown fuse or open circuit breaker. Replace fuse or reset circuit breaker and check amps.

Defective motor or capacitor. Replace.

Motor overloaded. Reset VFD and check amps.

Electrical.

Check for On/O switches. Check for correct supply

voltage. Check Control wiring.

Motor

starters

“chatter” or

do not pull in

Control power (24 VAC) wiring run is too

long. (Resistance should not

exceed 0.75 ohms).

Shorten wiring run to mechanical room or install a relay

to turn unit on/o. Consult factory for relay information.

Increase wire gauge size so that resistance is 0.75 ohms

or less.

Incoming supply power is less than

anticipated. Voltage supplied to starter

coil must be within +10% / -15% of

nominal voltage stated on the coil.

Need to increase supply power or use a special control

transformer which is sized for the actual supply power.

Motor over

amps

Static pressures are higher than design. Check for dirty lters. Improve ductwork.

Motor voltage incorrect.

Check motor wiring. Check motor nameplate versus

supplied voltage.

Motor horsepower too low.

See specications and catalog for fan curves to determine

if horsepower is sucient.

Shorted windings in motor. Replace motor.

Low airow

(cfm)

Unit damper not fully open. Adjust damper linkage or replace damper motor.

System static pressure too high.

Improve ductwork to eliminate losses using good duct

practices.

Blower speed too low.

Check maximum motor RPM and compare with catalog

data. Verify that external control wiring is in place if

required.

Fan wheels are operating backwards.

For 3-phase, see Direction of Fan Wheel Rotation

Direction in Start-Up, Components section.

Dirty lter.

Replace lters or follow cleaning procedures in Routine

Maintenance section of this manual.

Leaks in ductwork. Repair.

Elbows or other obstructions may be

obstructing fan outlet.

Correct or improve ductwork.

High airow

(cfm)

Blower fan speed too high.

Check for correct maximum fan RPM. Decrease maximum

fan speed if necessary in the VFD.

Filter(s) not in place. Install lters.

Insucient static pressure (Ps).

(airow resistance)

Induce Ps into system ductwork. Make sure grilles

and access doors are installed. Decrease fan speed if

necessary.

Excessive

noise or

vibration

Fan wheel rubbing on inlet.

Adjust wheel and/or inlet cone. Tighten wheel hub or

bearing collars on shaft.

Bearings.

Replace defective bearing(s). Lubricate bearings. Tighten

collars and fasteners.

Loose wheel on shaft. Tighten wheel hub.

Motor base or blower loose. Tighten mounting bolts.

Noise being transmitted by duct.

Make sure ductwork is supported properly. Make sure

ductwork metal thickness is sized for proper stiness.

Check duct size at discharge to ensure that air velocities

are not too high.

Always have a completed Pre-Start-Up Checklist and Start-Up Checklist prior to requesting parts or service information.

Loading...

Loading...