5

READ INSTRUCTIONS

BEFORE OPERATING

psi

0

5

10

15

20

TOP

TOP

3. Select fresh, firm food. Sort food according to size. Clean food thoroughly.

Prepare according to recipe. Fill hot Mason jars promptly with food and liquid

to recommended level. Allow ½-inch headspace for fruits. Most vegetables and

meats require 1-inch headspace due to expansion during processing. Work out

air bubbles with a clean, nonmetallic spatula. Wipe sealing edge clean with a

damp cloth. Adjust screw bands according to closure manufacturer’s directions.

4. Place three quarts of hot water and the canning rack in canner (Fig. D). For hot

packed foods, the water can be heated to 180°F, which is not quite boiling. To

prevent water stains on jars, add 2 tablespoons white vinegar to water in canner.

Always use the canning rack; jars may break if set directly on bottom of canner.

Note: Three quarts of water are needed no matter how many jars are being canned.

5. Place filled jars on canning rack immediately after each jar is filled.

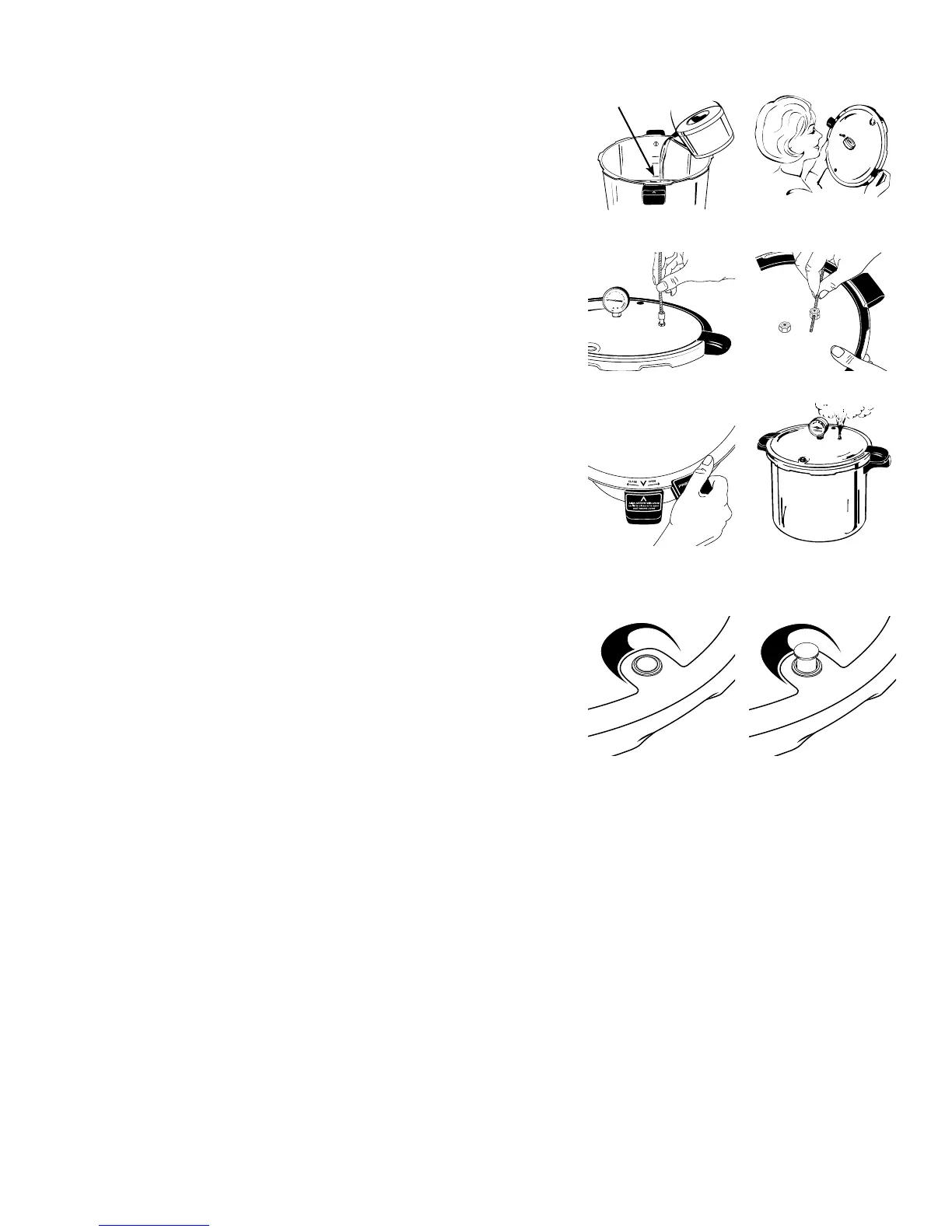

6. Hold cover up to the light and look through the vent pipe (Fig. E) to be certain

it is clear before placing the cover on the canner. If clear, proceed to step 7. If

blocked or partially blocked, clean the vent pipe with a small brush or pipe cleaner

(Fig. F). Also clean the vent pipe nut as shown (Fig. G).

7. Place cover on canner, aligning the V mark on the cover with the

V

mark on the

body handle (Fig. H). Press down on the cover handles to compress the sealing

ring; turn the cover in the direction indicated to close (clockwise) until the cover

handles are above the body handles. Do not rotate the cover beyond this point.

8. Position canner on a level burner and range only. Use on a tilted burner or range

may interfere with the operation of the pressure regulator. For electric coil and

smooth-top ranges, use the element that most closely matches the 8-inch diameter

of the canner bottom. This is the portion of the canner bottom which comes in

contact with the element.

To prevent damage to the pressure canner, do not use on any outdoor LP gas

burner or a gas range over 12,000 BTU’s. A high BTU burner will soften the

canner causing the bottom to warp. It may also result in property damage and/

or personal injury.

Using a relatively high heat setting, heat the pressure canner until a steady flow

of steam can be seen, heard, or felt coming from the vent pipe (Fig. I). Exhaust

air from the canner for 10 minutes by allowing steam to flow from the vent pipe.

Reduce heat, if necessary, to maintain a steady, moderate flow of steam.

9. Place pressure regulator on vent pipe. If heat was reduced for exhausting, adjust

to a relatively high setting and heat canner. As pressure develops in canner, the

air vent/cover lock will lift and lock cover on canner.

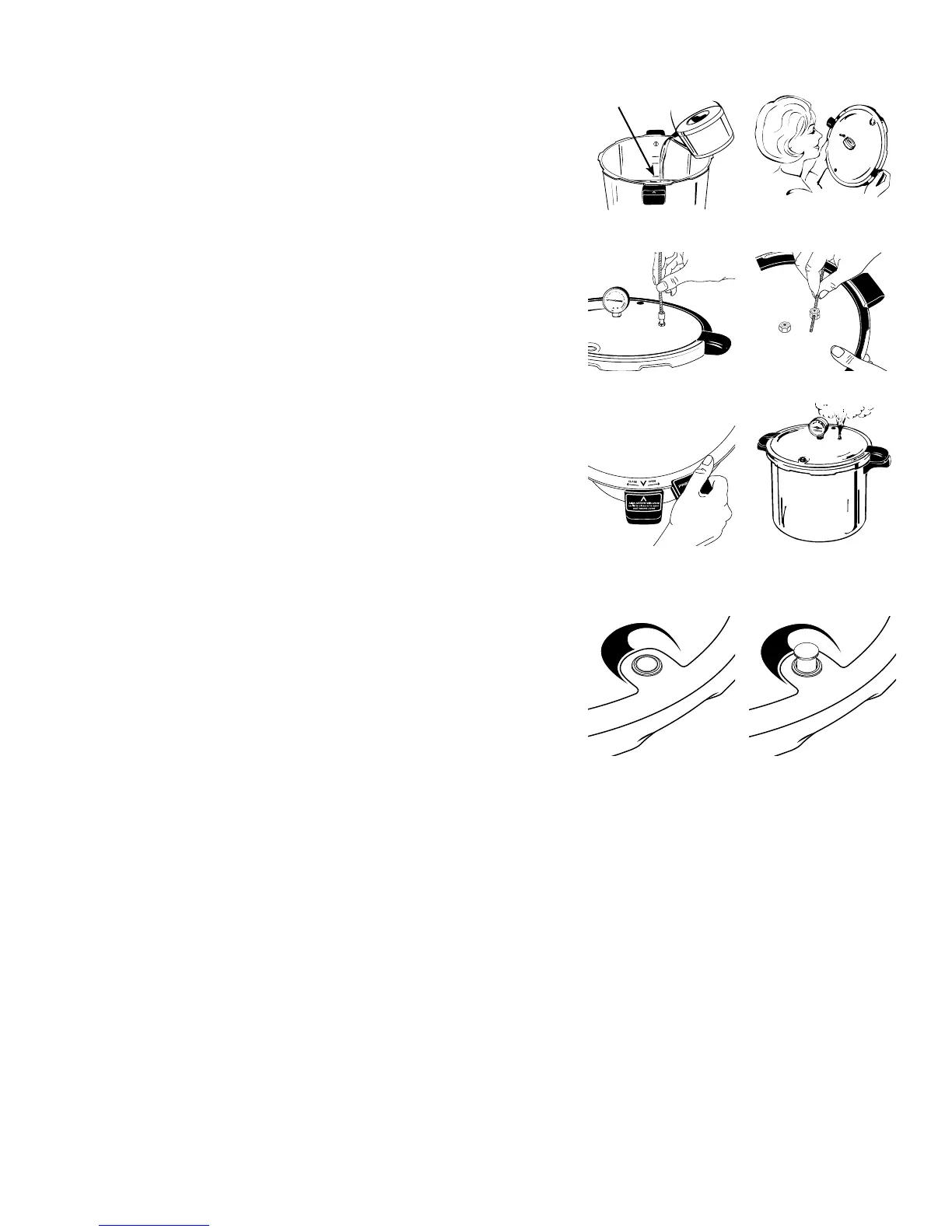

The air vent/cover lock is a visual indicator of the presence of pressure. When in the up position, pressure is in the canner; when in

the down position, there is no pressure in the canner (Fig. J). Also, as pressure builds, the pointer of the gauge will move across the

face. Continue heating until the pressure dial gauge registers the correct pressure. Adjust heat to maintain the correct pressure on the

dial gauge. The pressure regulator will rock ONLY at 15 pounds of pressure.

10. Processing time begins when the pressure dial gauge registers the correct pressure. Adjust heat to maintain correct pressure on the

pressure dial gauge. If pressure drops below desired setting, it will be necessary to bring pressure to the correct setting and begin

processing countdown from the beginning for the full amount of time.

Helpful Hint: To more easily maintain pressure, it may be beneficial to reduce the heat when the pressure dial gauge registers 1½–2

pounds less than the desired pressure. However, do not begin the processing countdown until correct pressure is reached.

11. At the end of processing time, turn burner to off and remove canner from heat source. NOTICE: Lift pressure canner to remove it

from burner. Sliding any cookware may leave scratches on stovetops.

12. Let pressure drop of its own accord. Do not attempt to speed the cooling of the canner, which can cause jar breakage, liquid

loss from the jars, and other problems. Pressure is completely reduced when the air vent/cover lock and overpressure plug have

dropped and no steam escapes when the pressure regulator is lifted. Do not use the pressure dial gauge as an indicator for when

pressure is completely reduced.

13. When pressure has been completely reduced, remove the pressure regulator from the vent pipe and let the canner cool for 10 minutes.

Do not remove the pressure regulator until pressure is completely reduced and the air vent/cover lock has dropped. Always remove

the pressure regulator before opening the cover.

Fig. D

Fig. E

Fig. F Fig. G

Align the V mark on the

cover with the

V

mark

on the body handle.

Fig. H

3-quart water line

(lowest mark)

Fig. I

Air vent/cover lock in UP

position. Pressure in unit.

Air vent/cover lock in DOWN

position. No pressure in unit.

UNLOCKED

Fig. J

LOCKED

Loading...

Loading...