6

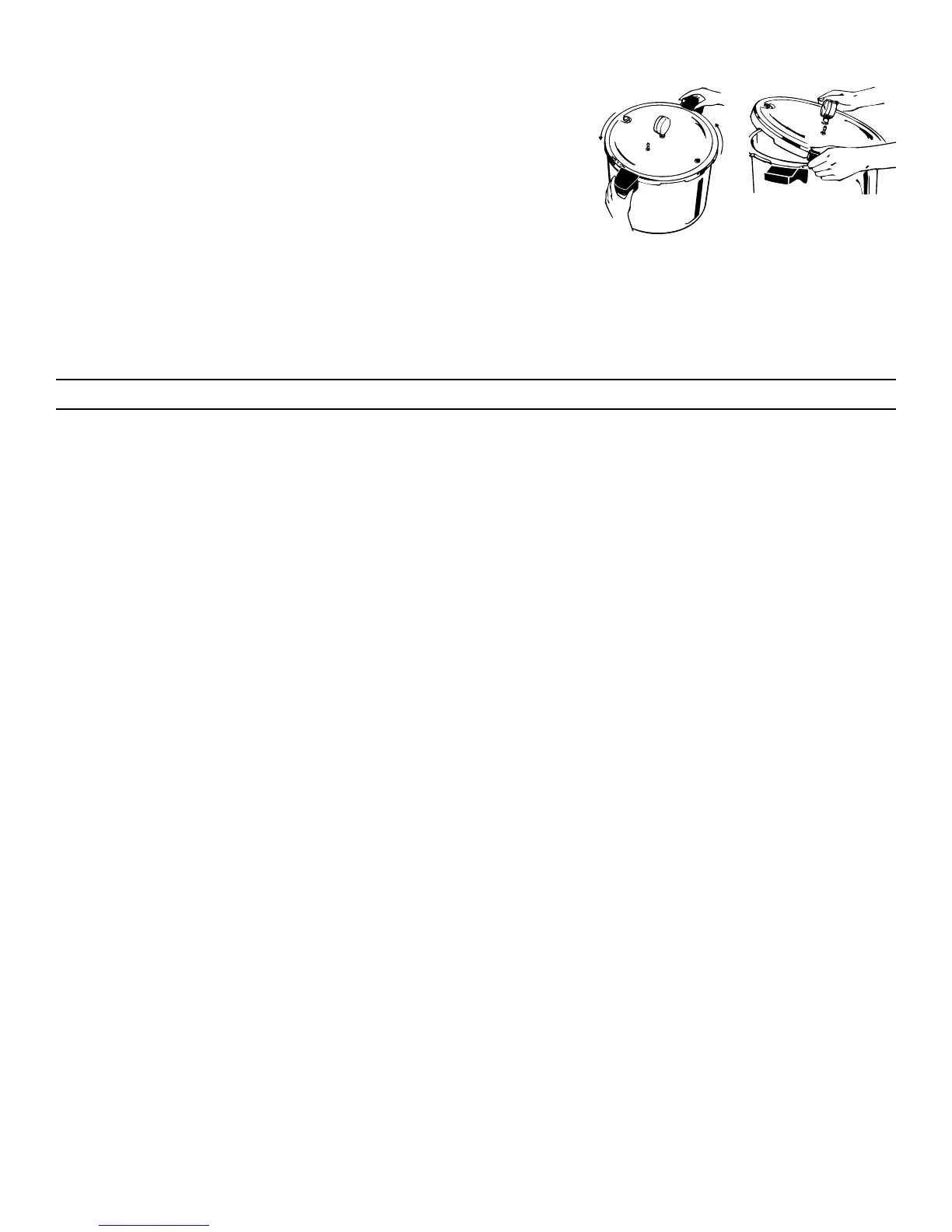

14. To remove cover, turn counter-clockwise until cover hits stop (Fig. K). Cover

handles will be beyond the body handles. CAUTION! If cover seems to stick

or is hard to turn, do not force it open. Sticking may indicate that there is still

pressure inside the canner. If in doubt about pressure being completely reduced,

let the canner stand until cool before removing the cover.

15. Lift cover toward you to keep steam away from you when opening (Fig. L).

16. Remove jars from canner. Set jars upright on board or cloth, away from drafts,

to cool. When jars are cold, test seal, remove bands, wipe jars, label, date, and

store in a cool, dry place. NOTICE: When processing consecutive batches,

be sure to check the water level in the canner between batches. Add water, if

necessary, to keep water at the 3-quart mark (see page 5, Fig. D).

17. When canning is complete, allow canner to cool completely before cleaning.

Canner Storage: When your canner is not in use, store it in a dry place at temperatures above freezing with the cover inverted on the

canner body. Storing the canner with the cover locked on may cause unpleasant odors and deform the sealing ring. Before storing, allow

the canner to dry completely.

HELPFUL HINTS FOR CANNING

Bubbles often appear in the jar after removal from the canner because food is still boiling in the jar. Ordinarily bubbles do not appear

once the product has been allowed to thoroughly cool.

Jar breakage during processing is caused by (1) packing jars too solidly or overfilling them; (2) weakened, cracked jars; (3) jars

touching the bottom of canner; (4) improperly tightened lids; or (5) using jars other than Mason jars.

Liquid lost from jars during processing is caused by (1) packing jars too solidly or overfilling them; (2) an insufficient exhaust period;

(3) a variation or sudden reduction of pressure in the canner—allow pressure to drop naturally; or (4) the failure to adjust the jar lids

according to manufacturer’s directions. If liquid is lost during processing, do not open the jar to replace the liquid. Loss of liquid will

not cause spoilage, but food above the liquid will discolor. If at least half of the liquid is gone, place the jar in the refrigerator and

use the food within 2–3 days.

It is better to overprocess food than underprocess. Underprocessing may result in spoilage and unsafe food.

Flat sour, a type of food spoilage, is caused by canning overripe food or allowing precooked foods to stand in jar too long before

processing. It may be prevented by using fresh products and properly processing, cooling, and storing. Flat sour shows no indication

of spoilage until jar is opened. Discard contents.

Food spoilage or jars not sealing is caused by (1) the failure to follow exact timetables and recipes; (2) the failure to wipe the sealing

edge of the jar clean before placing the lid on the jar; (3) having foods, seeds, or grease lodged between the lid and the jar; (4) using

jars which are nicked, cracked, or have sharp sealing edges; (5) the failure to adjust jar lids according to manufacturer’s directions;

or (6) turning the jars upside down while the jars are cooling and sealing.

If a jar does not seal, refrigerate it and use the food within 2–3 days. Otherwise, reprocess or freeze the food within 24 hours. Freeze

or repack using new lids. Reprocess for the full recommended processing time.

Mold can form only in the presence of air. Therefore, the jars are not sealed if mold is present. Discard the contents.

The black deposit sometimes found on the underside of a lid is caused by tannins in the food or hydrogen sulfide which is liberated

from the food by the heat of processing. This does not indicate spoilage.

Two-piece canning closures seal by the cooling of the contents of the jar, not through pressure of the screw band on the lid. Therefore,

although the screw band is firmly tight, the jar is not sealed until cooled. During processing, the flexible metal lid permits air to be

exhausted from the jar.

Adjust the two-piece canning closures by screwing the bands down evenly and firmly until a point of resistance is met (finger tight).

Do not use undue exertion.

The loss of color from beets during canning is usually due to the variety of beets used or using beets that are too old. If possible, can

young, tender, very dark beets which are freshly gathered. Precook beets with 2 inches of the stem and all of the root on, as this helps

to retain the juices.

Fruit which has been canned without sugar will often turn brown when exposed to air just as fresh fruit does.

The diameter of Mason jars may vary from one manufacturer to another. Before filling Mason jars, test load your canner. It may be

necessary to double-deck pint and half-pint jars to reach the maximum capacity of your canner as shown in the chart on page 4. It is

recommended that you stagger the jars by placing one jar on top of two. Jars may touch. The canning rack which accompanied your

pressure canner must be placed on the bottom of the canner to prevent jar breakage. Although it is not necessary to use a rack between

layers of jars, if you wish to do so, a rack can be ordered from the Presto Consumer Service Department (see page 33).

Fig. LFig. K

Loading...

Loading...