57289

REVISED

2.1.06

8

bracket. Install existing OEM bolts

through bracket, spacer and into the two

bottom holes (with loctite). Torque to 70

ft./lbs.

b) Install 1-1/8” spacer tube at rear

of upper OEM rubber mount with 1/2” x

2-1/2” hex bolt, 1/2” flat washer and 1/2”

nyloc nut. Torque to 70 ft./lbs.

c) Install 3/4” spacer tube at rear of

upper OEM rubber mount with 1/2” x 2-

1/4” bolt, 1/2” flat washer and 1/2” nyloc

nut. Torque to 70 ft./lbs.

10) Install passenger side differential

drop bracket using 1/2” x 1-1/4” hex bolt

with 1/2” flat washer and nyloc nut into

upper hole of OEM rubber mount. Wide

part of bracket should be at bottom with

hole towards front, as shown in ILLUS-

TRATION 6. Reinstall OEM bolt through

bracket and into side of differential (using

loctite). Torque to 70 ft./lbs.

11) Install driver side differential

drop bracket using OEM bolts in two

bottom holes (using loctite). Use 1/2” x

1-1/4” hex bolts, 1/2” flat washers and

1/2” nyloc nuts in two upper holes.

Torque to 70 ft./lbs. See ILLUSTRA-

TION 7.

12) Remove tie rods from steering

knuckles. Remove two bolts on back

side of spindle which hold the metal

bracket for the brake hose.

13) Support lower a-arm with floor

jack and separate upper ball joint from

spindle. Using file, file corners off of

spindle to contour with bottom of new

spindle adapter so that the bottom of

the new spindle seat surface is in con-

tour with OEM spindle top surface.

Clean out hole on top of steering

knuckle (spindle).

ILLUSTRATION 7

FLAT

WASHER, 1/2”

HEX BOLT,

1/2” X 1

1/4” LG.

DRIVER SIDE

DIFFERENTIAL

DROP BRACKET

90-1283

NYLOC NUT, 1/2”

FLAT WASHER, 1/2”

EXISTING

PASSENGER SIDE SHOWN

F

R

O

N

T

O

F

V

E

H

I

C

L

E

EXISTING

(USE

LOCTITE)

EXISTING

(USE LOCTITE)

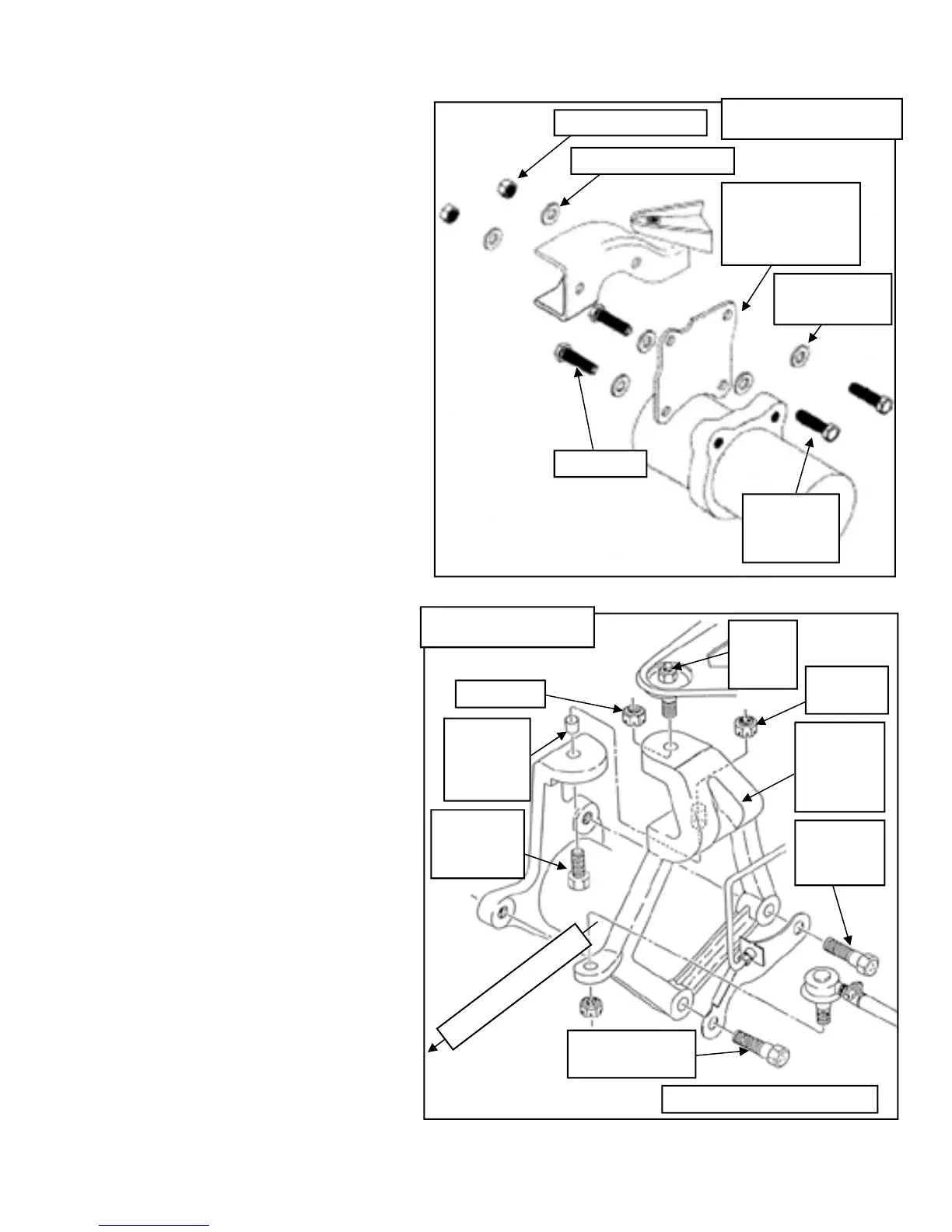

ADAPTER

SPINDLE

90-4010

90-4009

LOCK

NUT, 5/8”

UPPER

BALL

JOINT

EXISTING

TAPERED

SPINDLE

SLEEVE

96-4026

HEX

BOLT, 5/8”

X 2-1/2”

ILLUSTRATION 8

Loading...

Loading...