8612517 200A SPOOL GUN KIT V1.0

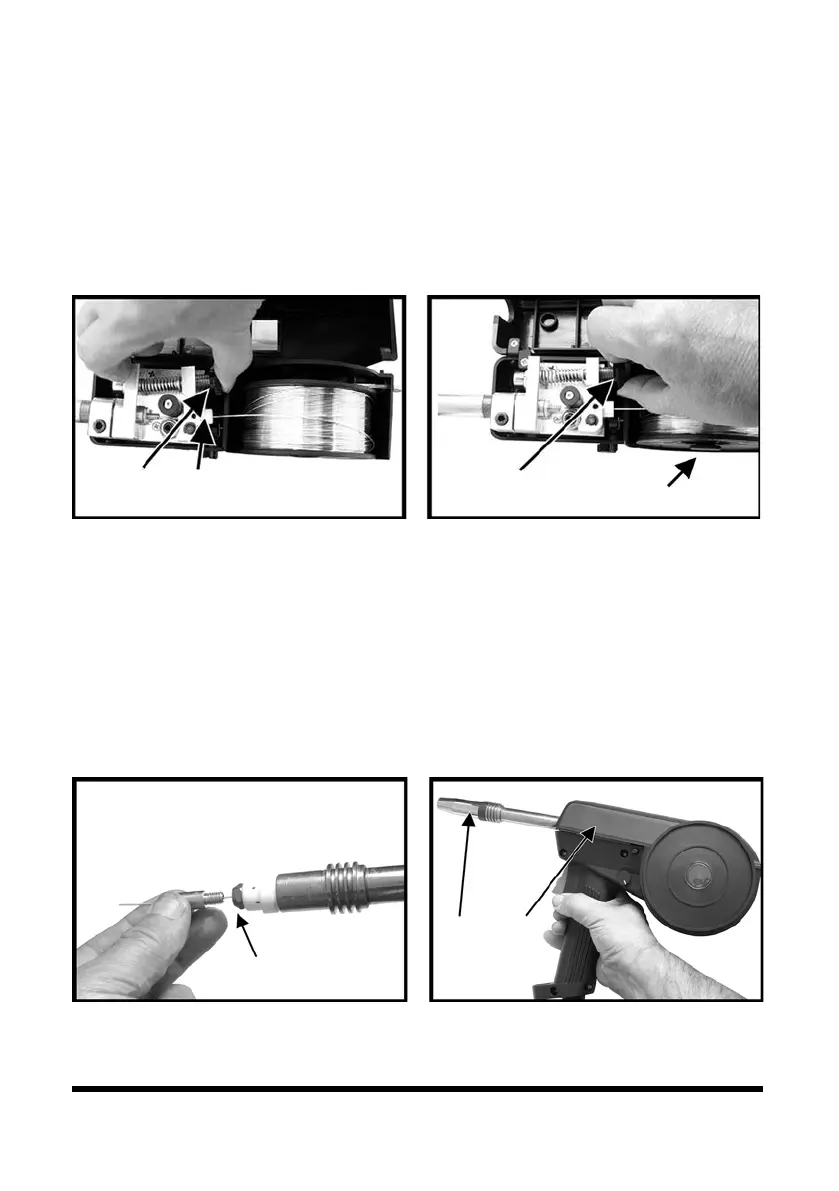

12. Align the wire into the groove of the drive roller and release

the tension arm. Check that the wire is in the drive roller’s

groove.

13. Apply an adequate amount of pressure to the drive roller

by winding in the tension adjusting knob (Fig. 5-1).

14. Adjust spool holder tension with the knob (Fig. 5-2).

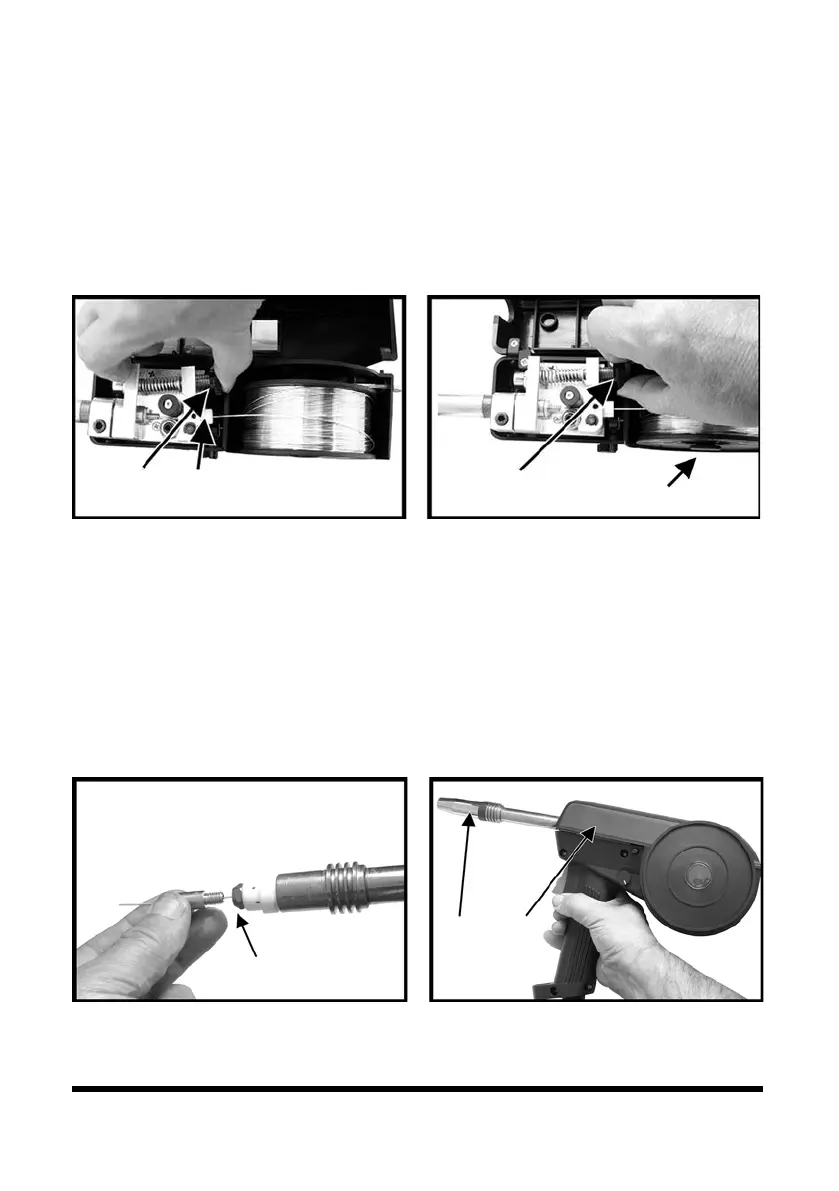

15. Remove the gas nozzle and contact tip from the torch

neck, Pull the trigger to drive the wire through the neck

until it exits the contact tip holder (Fig. 6).

16. Fit the correct sized contact tip and feed the wire through

it, screw the contact tip into the tip holder of the torch

neck and nip it up tightly (Fig. 6-1).

17. Fit the gas nozzle to the torch head (Fig. 7-1) and close the

wire spool cover. (Fig. 7-2).

18. Follow the instructions in the welding machine manual to

set up the gas flow and welding parameters.

6 For technical questions call 1-800-665-8685

Loading...

Loading...