- 13 -

3. Installation

3.1. Installation of the piping

CAUTION!

Inappropriate piping may result in damaging the compactor or carrier and shortening of its life.

Be sure to follow our regulations on pipe installation.

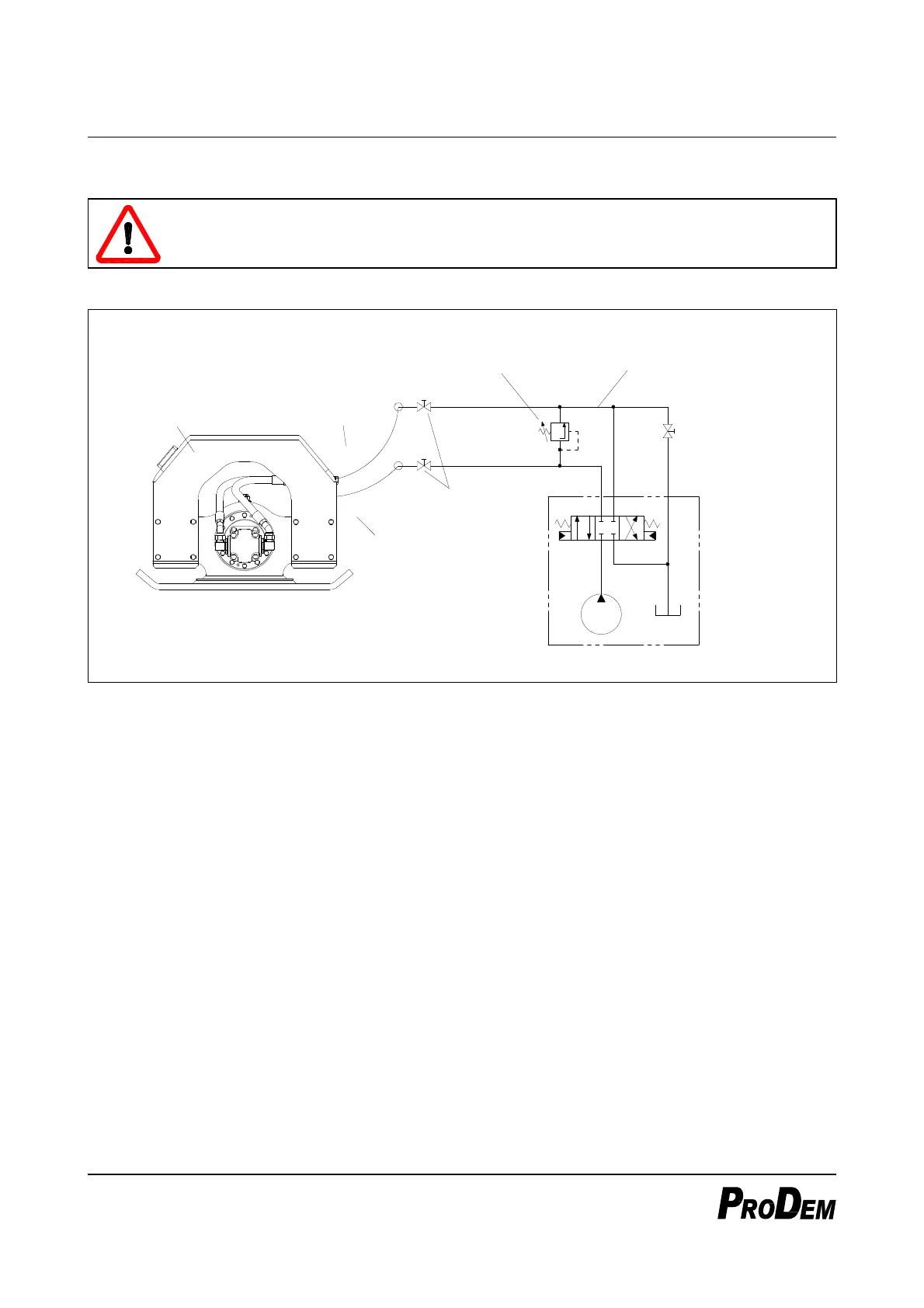

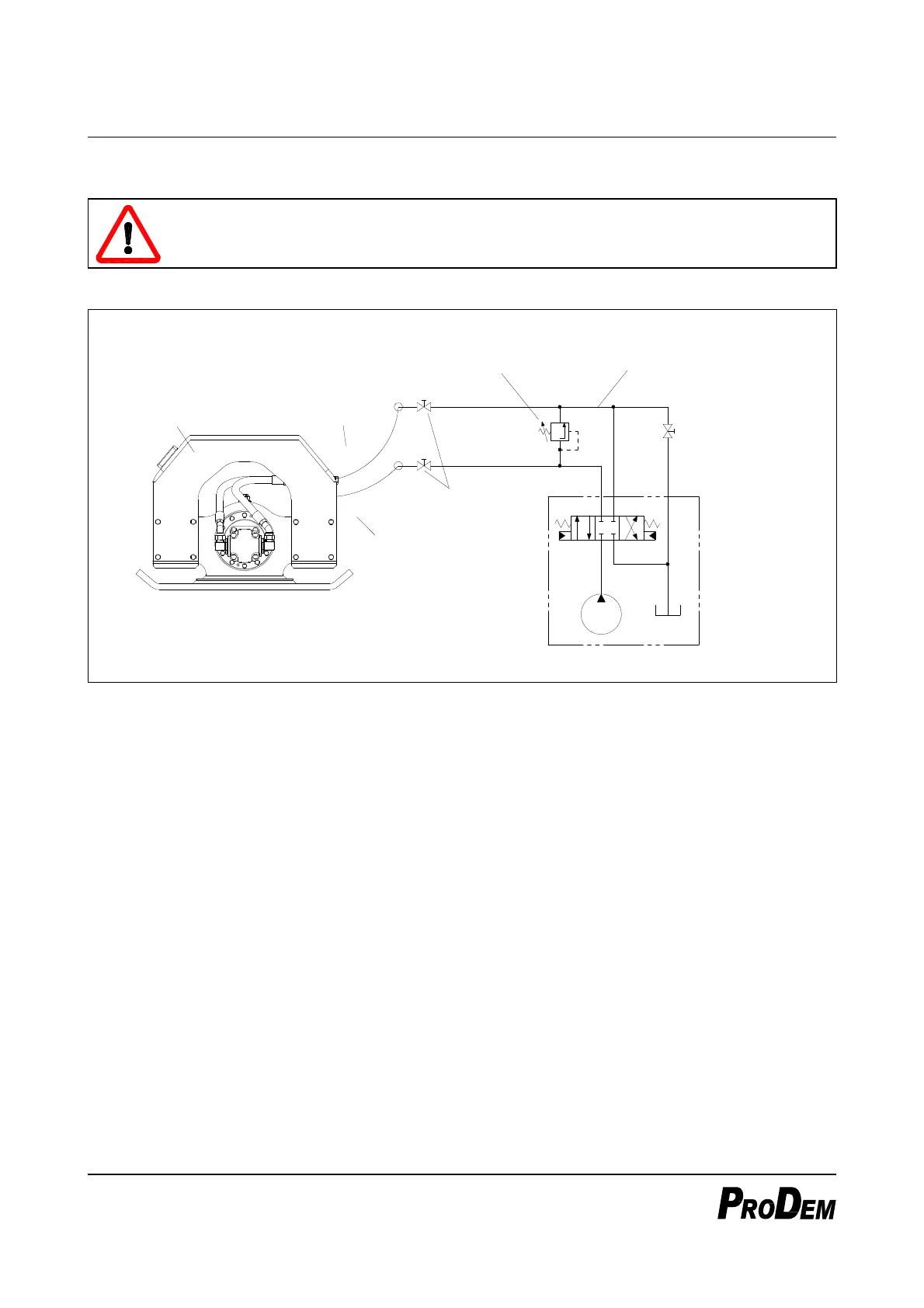

Hydraulic Circuit Diagram (recommended)

Compactor

'P' Port

(IN)

'T' Port

(OUT)

Stop Valve

Relief Valve

(See ※)

Drain line

(necessarily required)

Stop Valve for

by-directional

operation

(option)

★ Carrier's hydraulic systemmay vary depending

on the model and maker.

P

T

P

T

A

B

Figure 12 The above circuit diagram is for reference only.

The specifications of carrier’s hydraulic system required to operate the compactor is as follows.

Pump Flow: Higher than the minimum working flow of the compactor

System Pressure: 180 bar or higher

Allowable Back-Pressure: 15 bar or less

Compactor piping is basically the same as breaker piping, and thus it is possible to use the breaker piping

as it is without any modification.

★ But, the drain(low-pressure) line must be connected directly to oil cooler or oil tank.

If the drain line is connected to the control valve of the carrier, the compactor’s motor can be

damaged.

If the drain line of carrier has a stop valve for by-directional operation, be sure to operate the compactor

with opening the stop valve.

The drain line should has sufficiently large inner diameter to meet the specified maximum acceptable

back-pressure of the compactor. If the back pressure – measured at the ‘T’ port during operation – is

higher than the specified value, check the inner diameters of pipes, hoses or fittings of the drain line.

Loading...

Loading...