- 29 -

6. Operating the hydraulic hammer

This chapter describes how to choose the correct chisel for the job and how to operate the hammer correctly.

To increase the hammer’s breaking performance and working life, pay attention to this chapter.

The hammer is powerful machinery and lots of damage can be done if you do not know how to use the

hammer safely. Read this chapter before operating the hammer.

6.1. Selecting the right chisel

The correct type of chisel must be selected to get the best possible working results and longest lifetime for

chisel.

The recommended selections of standard chisels for various kind of job are depicted as follows:

Basically, there are two types of breaking principle with a hydraulic hammer.

Penetrative (or cutting) breaking:

A conical, pyramid or wedge type tool is forced into the material. This method is most effective in soft,

layered or plastic material. The sharper edge the chisel has, the better the hammer penetrate the material.

However, breaking hard material will cause the sharp edges to wear very quickly.

Impact breaking:

Transferring strong mechanical stress wave into material breaks material. Best possible energy transfer

between chisel and material is achieved with a blunt chisel. This impact breaking is more effective in hard,

brittle and very abrasive materials. Generally, small size hammer is not suitable for impact breaking.

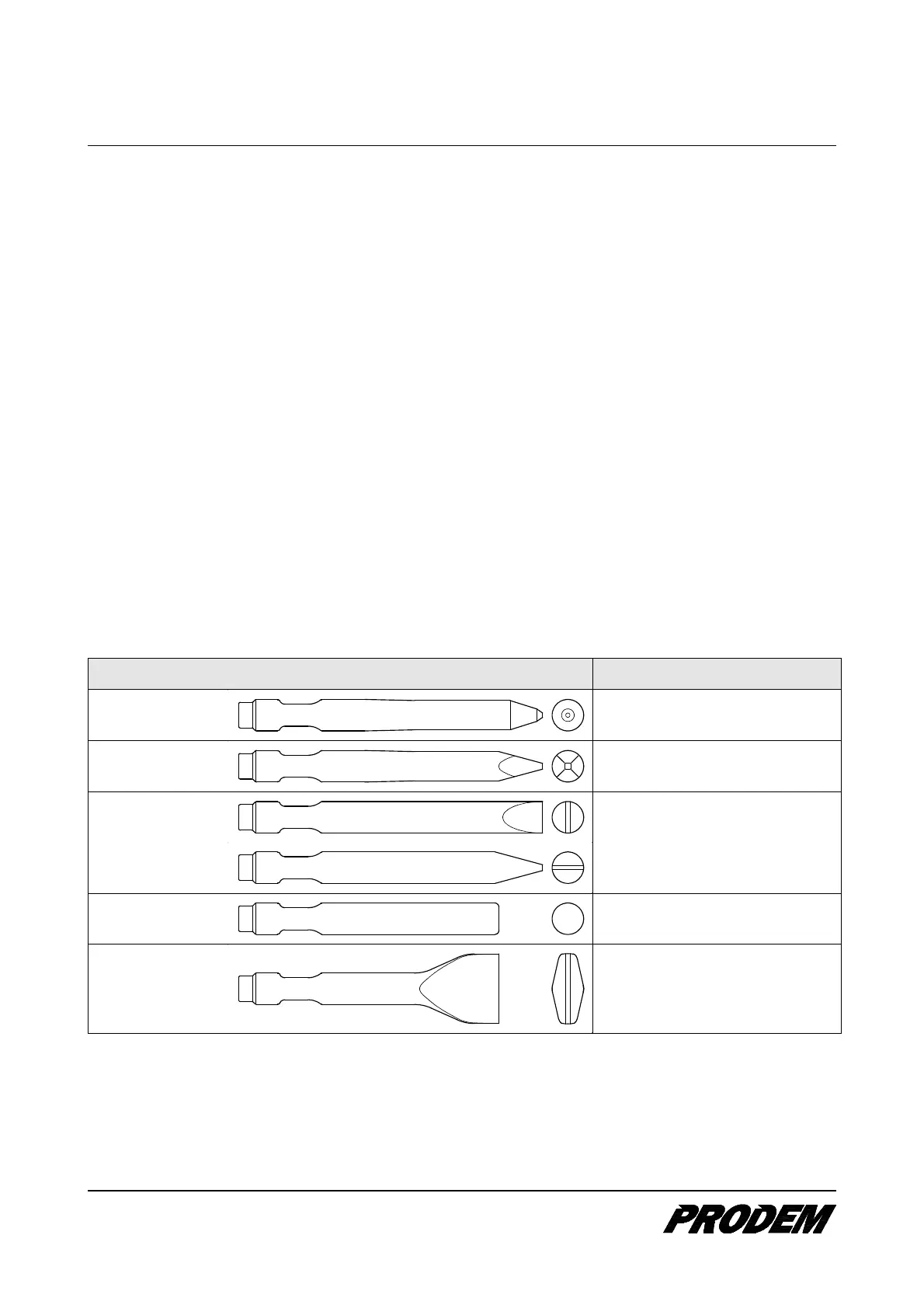

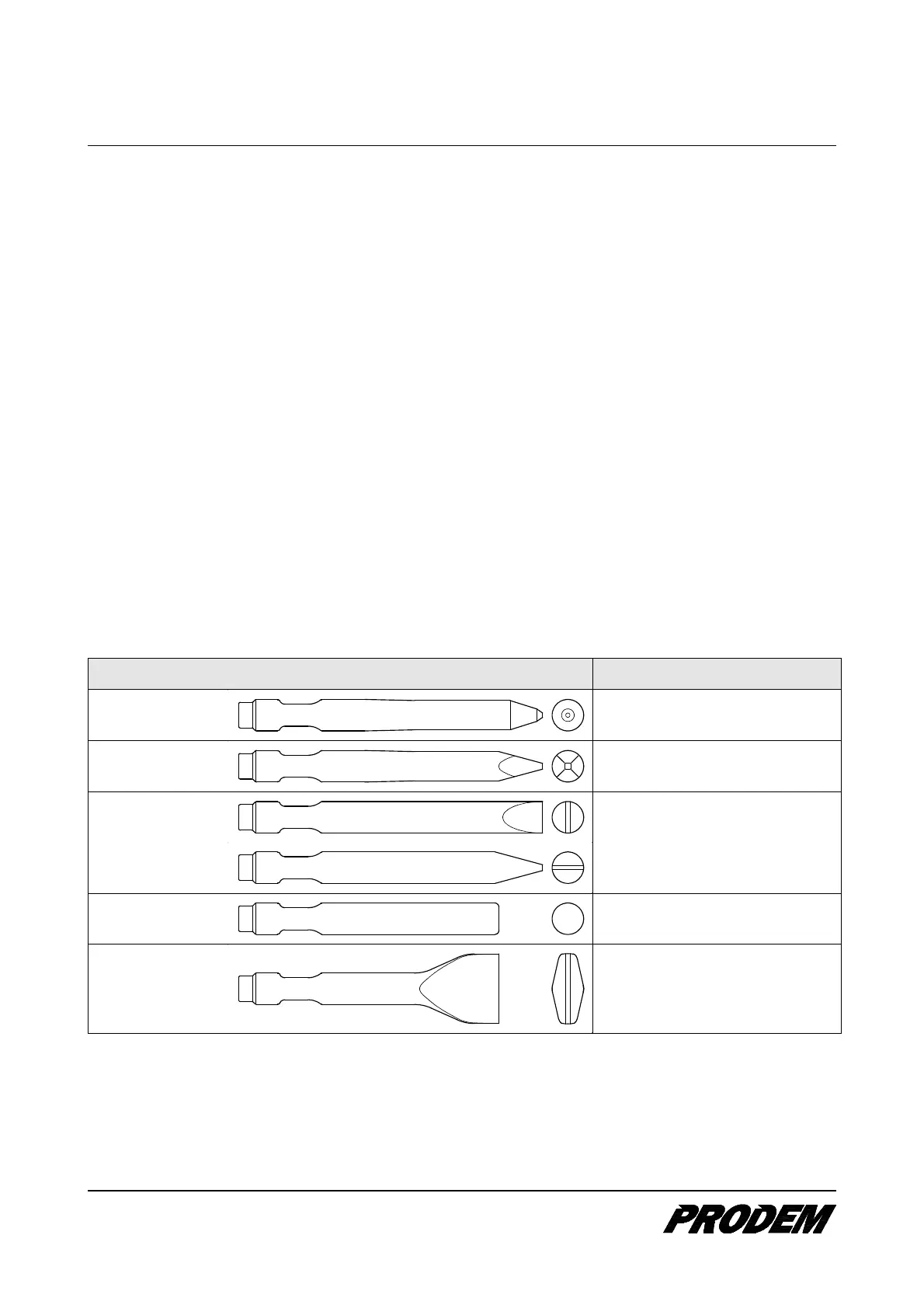

Standard chisels:

Type of Chisel Application

Moil point

(Conical)

Universal use; Breaking concrete,

bedrock and pavement

Moil wedge

(Pyramid)

Universal use; Breaking concrete,

bedrock and pavement

Flat wedge

- cross-cut

- inline-cut

Mining, Foundation,

Trenching and benching,

Concrete demolition,

Finishing slopes

Flat end

(Blunt)

Breaking oversize boulders,

Concrete demolition

Wide flat wedge

(Asphalt cutter)

Mining, foundation, trenching,

demolition, finishing slopes,

Breaking asphalt pavement

Note:

Chisels are subject to wear and tear in the course of normal operations. (Replacement of these parts due

to wear is not covered by the warranty.)

Only genuine PRODEM chisels should be used, if other makes of chisels are used the warranty may

become void.

Special designs available on request.

Loading...

Loading...